A test method for low temperature toughness

A test method and low-temperature toughness technology, which is applied in the field of low-temperature toughness testing, can solve problems affecting the accuracy of test results and sample temperature differences, and achieve the effects of simple installation, improved temperature stability, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

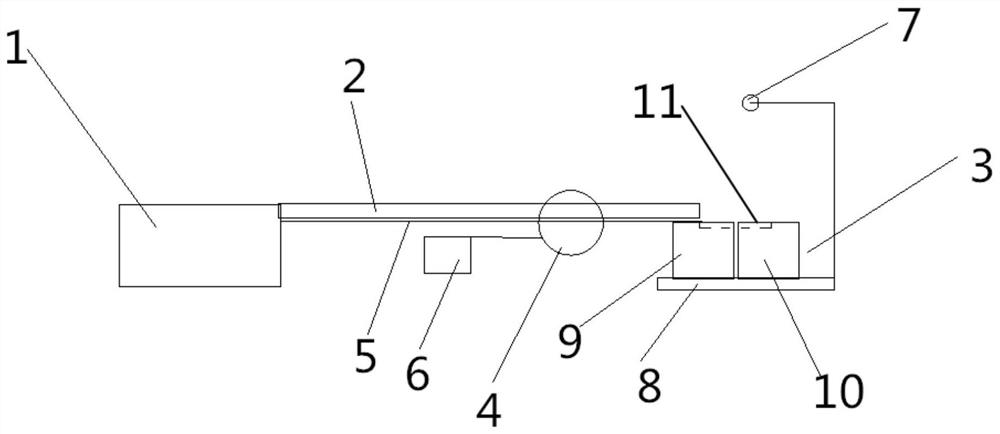

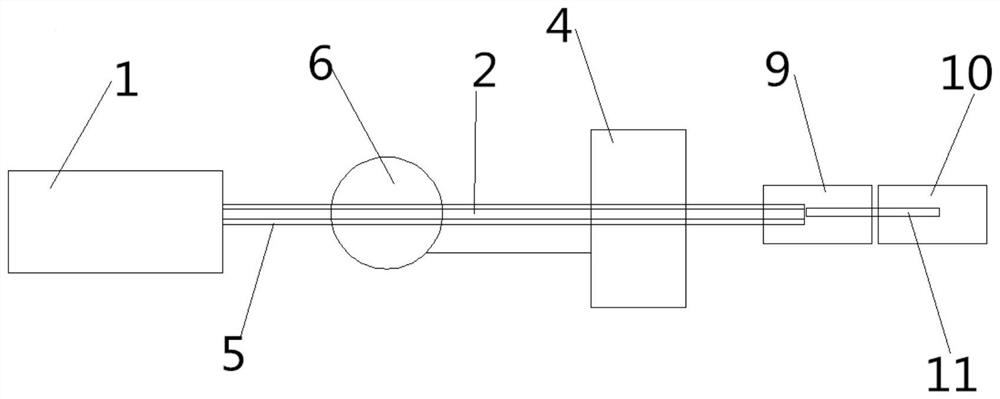

[0036] The technical solutions in the embodiments of the present application will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present application.

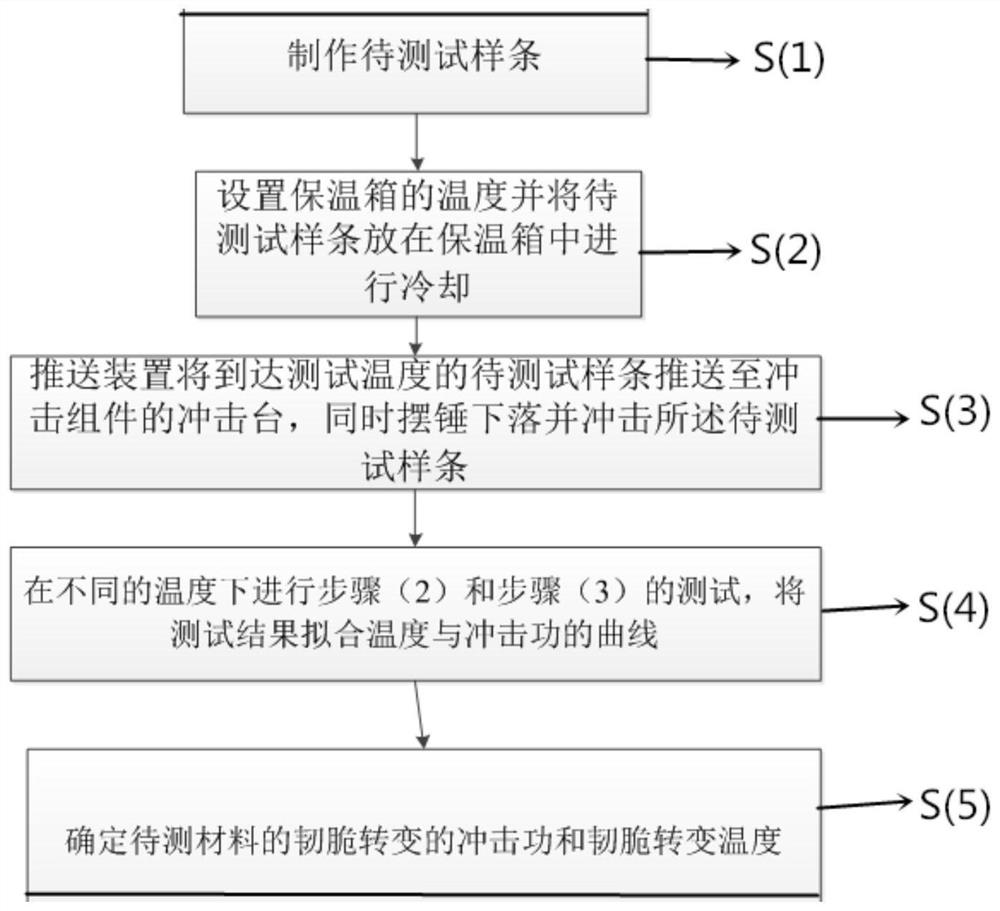

[0037] like Figure 1 to Figure 4 As shown, the present invention provides a test method for low temperature toughness, the method comprises the following steps:

[0038] S(1) Make the spline to be tested;

[0039] S (2) set the temperature of the incubator 4 and place the specimen to be tested in the incubator 4 for cooling;

[0040] S (3) Pushing device 1 pushes the specimen to be tested that reaches the test temperature to the impact table of impact assembly 3, and simultaneously the pendulum 7 falls and impacts the specimen to be tested;

[0041] S (4) carry out the test of step (2) and step (3) at different temperatures, and fit the curve of temperature and impact energy to the test result;

[0042] S(5) determines the impact energy and the ductile-brittle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com