Plastic composite sheet and its producing method

A composite sheet material and manufacturing method technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as low cost, and achieve the effects of prolonging service life, beautiful appearance, and excellent heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

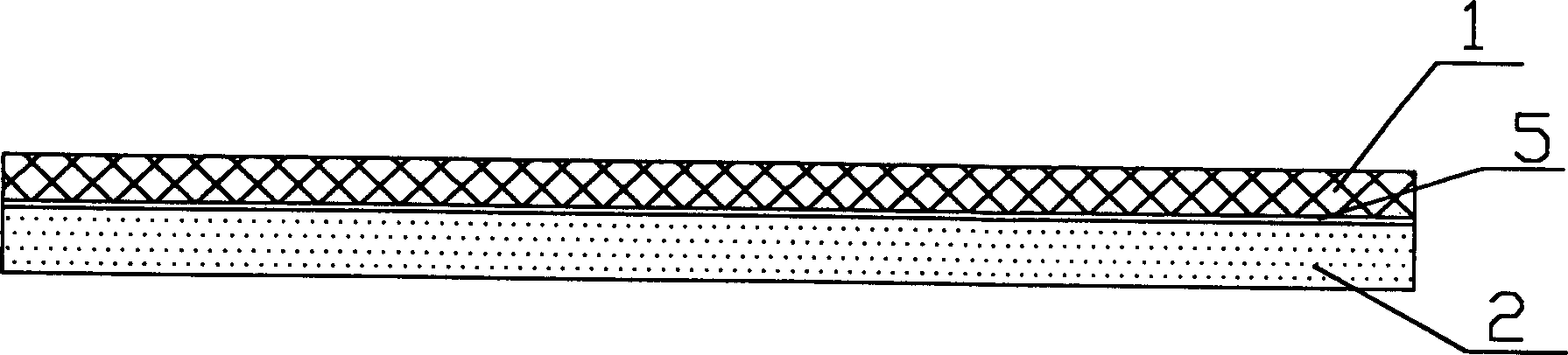

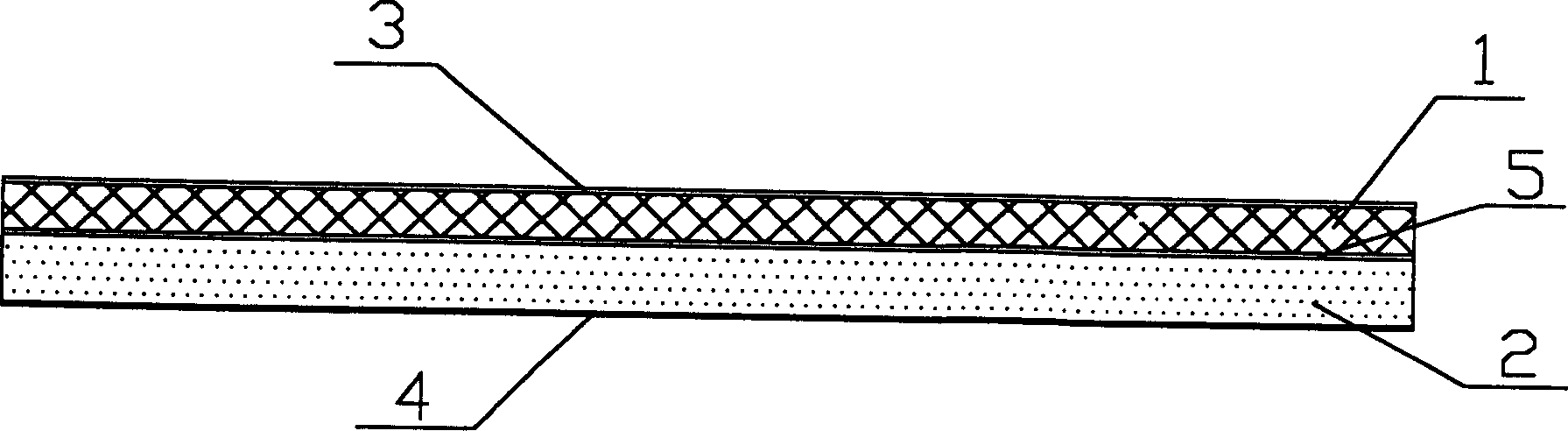

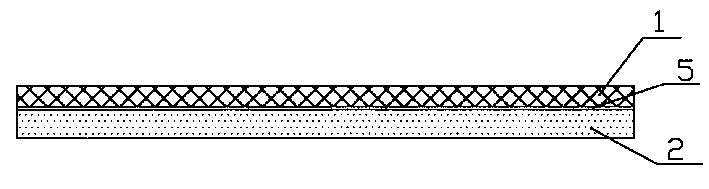

[0052] refer to figure 1 , The plastic composite sheet of the present invention comprises a surface layer (1), a middle layer (5) and a base layer (2).

[0053] Surface layer (1): PVC (intrinsic viscosity 120) plastic sheet with a thickness of 0.4mm;

[0054] Middle layer (5): an EVA film with a thickness of 0.02 mm, a vinyl acetate content of 17%, and a melt index of 135;

[0055] Base layer (2): a 20% random PP modified PP foamed plastic sheet with a thickness of 4mm;

[0056] Matting agent b coating (3): a coating coated with matting agent b on the outer surface of the surface layer (1) and pressed with a pattern, the thickness of the coating (3) is 0.01mm

[0057] Coating layer (4): coated with vinyl chloride resin on the bottom surface of the base layer (2), the vinyl chloride resin of the coating layer (4) is vinyl chloride / vinyl acetate diethylene oxide with a vinyl acetate content of 5% and an absolute viscosity of 1.80. meta-copolymer resin.

[0058] The compositi...

Embodiment 2

[0065] Such as figure 1 A plastic composite sheet as shown, wherein:

[0066] Surface layer (1): PVC (intrinsic viscosity number 150), thickness 0.6mm, pressed with patterns;

[0067] Middle layer (5): polyurethane hot melt adhesive (provided by Jiangsu Sentai Polymer Material Co., Ltd.), with a thickness of 0.03 mm.

[0068] Base (2): 10% LDPE modified PP foam plastic sheet, 5mm thick;

[0069] Coating (3): There is a matting agent b coating on the outer surface of the surface layer (1), and the composition of the matting agent is as follows:

[0070] Vinyl resin 1%

[0071] Tetrahydrofuran 98%

[0072] Silica 1%;

[0073] Wherein, the vinyl chloride resin used in the matting agent is a vinyl chloride / vinyl acetate binary copolymer resin with a vinyl acetate content of 13% and an absolute viscosity of 1.30.

[0074] Coating layer (4): Polyurethane sol is coated on the bottom surface of the base layer.

[0075] Preparation method: Coat the bottom surface of ...

Embodiment 3

[0077] Such as figure 1 A plastic composite sheet as shown, wherein:

[0078] Surface layer (1): PVC (intrinsic viscosity number 150) plastic sheet, thickness 0.6mm;

[0079] Middle layer (5): EVA film with a vinyl acetate content of 17%, a melt index of 135g / min, and a thickness of 0.06mm;

[0080] Base layer (2): PE with a melt index of 2.4g / min, which contains 25% EVA (melt index 5g / min, vinyl acetate content 20%) foam plastic sheet, thick 3mm;

[0081] Coating (3): There is a matting agent b on the outer surface of the surface layer (1), and the composition of the matting agent is as follows:

[0082] Vinyl resin (average degree of polymerization 1000) 30%

[0083] Tetrahydrofuran 60%

[0084] Silica 10%;

[0085] Among them, the vinyl chloride resin used in the matting agent is a vinyl chloride / vinyl acetate / maleic anhydride ternary copolymer resin with a chlorine content of 52% and a specific viscosity of 1.20.

[0086] Coating layer (4): Polyurethane s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com