Thermal pressed silicon rubber sheets and manufacture thereof

A silicone rubber sheet, thermocompression bonding technology, applied in the direction of rubber layer products, chemical instruments and methods, film/sheet adhesives, etc., can solve the increase of surface roughening steps, cost increase, anisotropy Problems such as poor surface release properties of conductive adhesives, to solve pollution problems, reduce costs, and avoid adhesion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

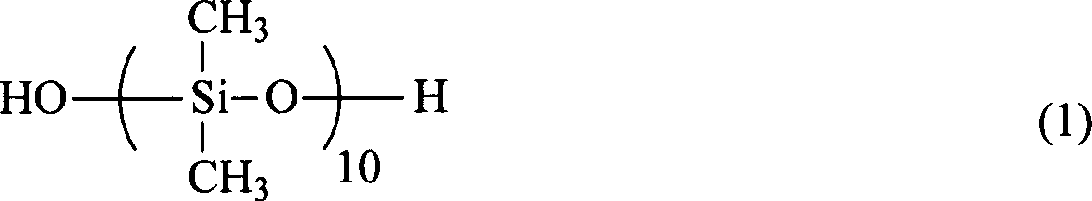

[0118] Using a kneader, 100 parts by weight of methylvinyl polysiloxane having an average degree of polymerization of 8,000, which is composed of 99.85 mol% of dimethylsiloxane units and 0.15 mol% of methylvinylsiloxane units Oxane, 400 parts by weight of alumina powder as a filler with good thermal conductivity: alumina AL-45 (manufactured by Showa Denko (KK)), 30 parts by weight of specific surface area of 200m 2 Silica fine powder per g: Aerosil 200 (manufactured by Japan Aerosil (KK)) and 5 parts by weight of α, ω-dihydroxymethylpolysiloxane represented by the following formula (1), uniformly mixed, And heat treatment at 150°C for 2 hours.

[0119]

[0120] After cooling, use a twin-roller to add 0.5 parts by weight of a silicone rubber compound with a specific surface area of 140 m to 100 parts by weight of the silicone rubber compound. 2 / g of cerium oxide powder, 1.5 parts by weight of organic peroxide as a curing agent: C-23 (manufactured by Shin-Etsu Chemical ...

Embodiment 2

[0129] 100 parts by weight of methylvinylpolysiloxane with an average degree of polymerization of 8,000 formed from 99.85 mol% of dimethylsiloxane units and 0.15 mol% of methylvinylsiloxane units using twin rolls In alkanes, the average particle diameter of mixing 50 parts by weight is 23nm, and the BET specific surface area of 0.10 weight % of volatile matter is 130m 2 / g of acetylene black, the BET specific surface area of 5 parts by weight is 120m 2 / g of hydrophobic silica (Aerosil R-972: trade name, manufactured by Degussa Co.) and 0.5 parts by weight of BET specific surface area is 140m 2 / g of cerium oxide powder, kneading and kneading to homogenize it.

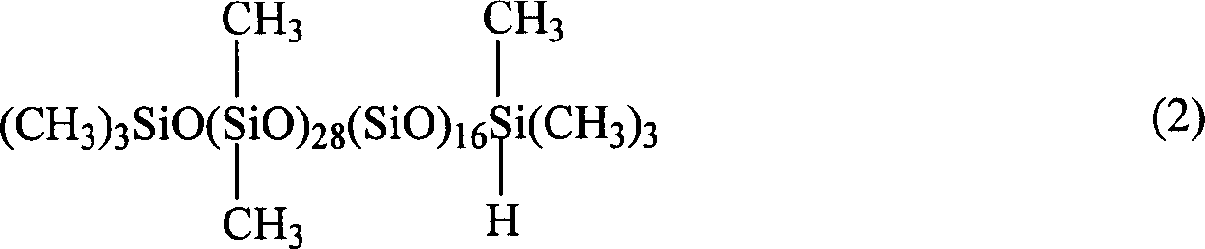

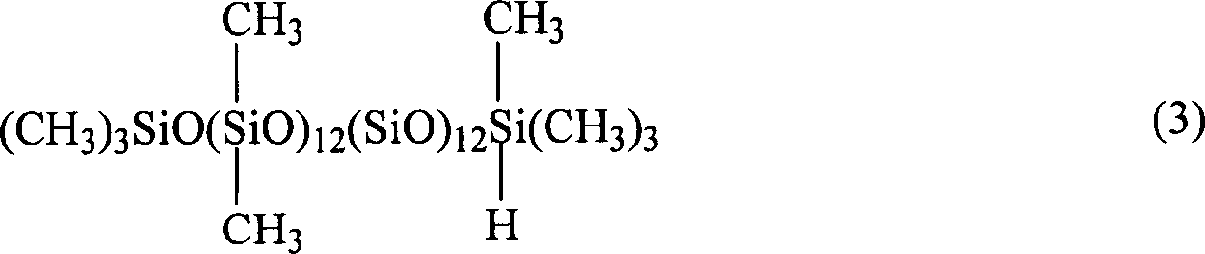

[0130] With respect to 100 parts by weight of the silicone rubber compound, 0.1 parts by weight of isopropanol solution of chloroplatinic acid (platinum content is 2% by weight), 0.1 parts by weight of ethynylcyclohexanol as a reaction inhibitor, and 1.2 parts by weight Parts of methylhydrogen polysiloxane repres...

Embodiment 3

[0137] A first silicone rubber layer with a thickness of 0.2 mm was prepared in the same manner as in Example 1.

[0138] The second silicone rubber composition was prepared in the same manner as in Example 1 except that polyorganosilsesquioxane was used to solidify the silicone resin powder with an average particle diameter of 10 μm. After heating and curing the composition at a temperature of 150°C for 5 minutes, and post-curing at a temperature of 200°C for 4 hours, the type A hardness thereof was measured as 55 by a JIS K 6253 Chow hardness tester.

[0139]The composition and molding method of the second silicone rubber layer are the same as in Example 1, the thickness of the second silicone rubber layer obtained is 10 μm, and the total thickness of the silicone rubber sheet formed by the combination of the first silicone rubber layer and the second silicone rubber layer is 0.21 mm and the same post-cured laminated silicone rubber sheet as in Example 1.

[0140] The surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com