Production method of PVDF (polyvinylidene fluoride) ferroelectric field effect transistor based on molybdenum disulfide film

A technology of electric field effect and molybdenum disulfide, which is applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problems of high switching ratio and unrealizable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

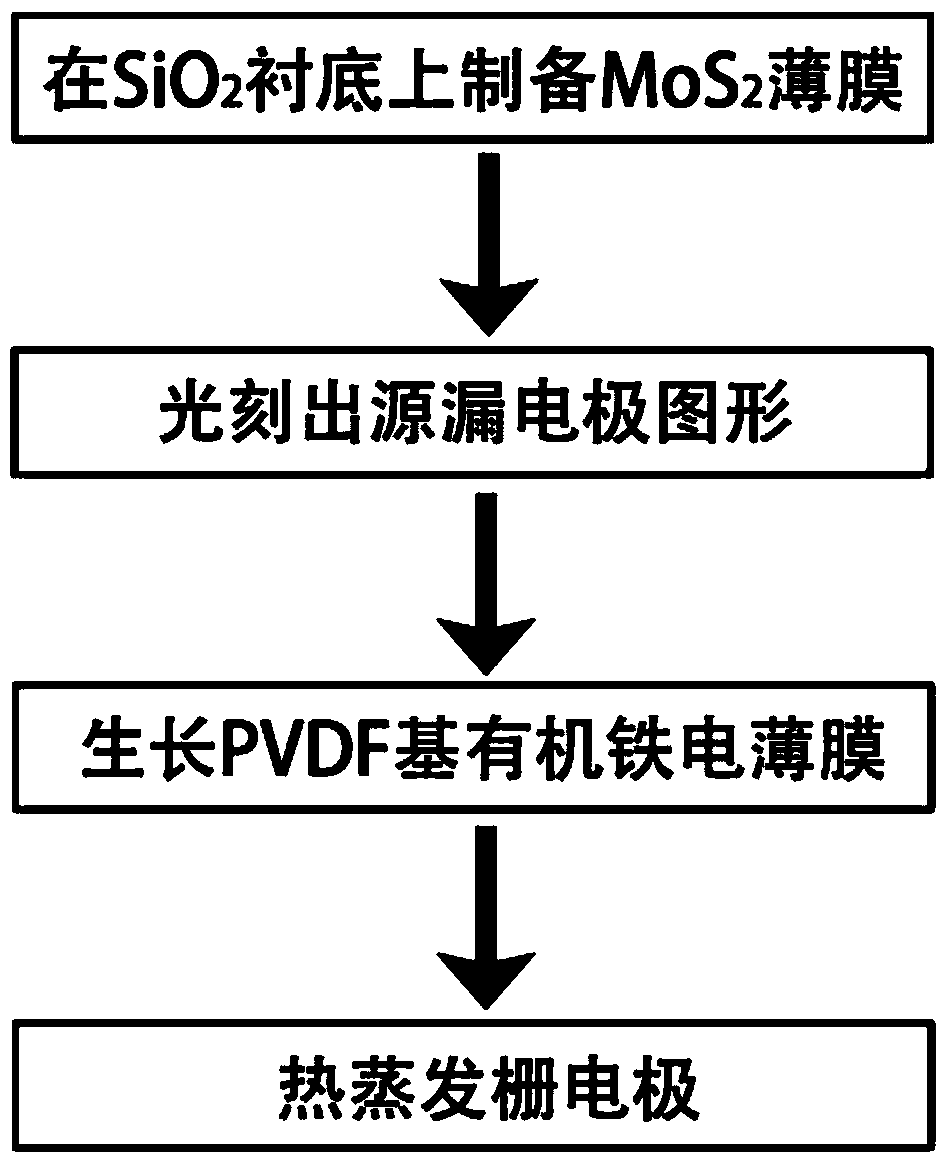

[0024] SiO 2 The substrate material is cleaned to ensure the cleanliness of its surface, and MoS is grown by chemical vapor deposition 2 film. Then in MoS 2 The surface of the film is spin-coated with photoresist, baked, exposed to ultraviolet light, developed, and baked to obtain the required source-drain electrode pattern structure; then the source-drain Au electrode is obtained through thermal evaporation of Au and lift-off steps;

[0025] The rotational speed of the spin-coated photoresist described therein is 4k rpm, the baking temperature is 85 degrees Celsius, and the ultraviolet light exposure time is 20 seconds.

[0026] The PVDF-based polymer P(VDF-TrFE) is dissolved in a dimethyl sulfoxide solution, and the concentration of the solution is 0.01% by mass. Then the P(VDF-TrFE) organic ferroelectric polymer dimethyl sulfoxide solution is evenly spread into the liquid tank of the Langmuir-Brockett device that has been injected into the static ultrapure water, and the...

Embodiment 2

[0032] SiO 2 The substrate material is cleaned to ensure the cleanliness of its surface, and MoS is grown by mechanical exfoliation 2 film. Then in MoS 2 The surface of the film is spin-coated with photoresist, baked, exposed to ultraviolet light, developed, and baked to obtain the required source-drain electrode pattern structure; then the source-drain Au electrode is obtained through thermal evaporation of Au and lift-off steps;

[0033]The rotational speed of the spin-coated photoresist described therein is 4k rpm, the baking temperature is 85 degrees Celsius, and the ultraviolet light exposure time is 20 seconds.

[0034] The PVDF-based polymer P(VDF-TrFE) is dissolved in a dimethyl sulfoxide solution, and the concentration of the solution is 2.5% by mass. Then the P(VDF-TrFE) organic ferroelectric polymer dimethyl sulfoxide solution was transferred layer by layer to MoS by spin coating. 2 A ferroelectric film with a certain thickness is obtained on a patterned substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com