Preparation method of polyurethane and sericin medical composite film with water absorption and moisture permeability

A technology of sericin and composite film, which is applied in the direction of absorbent pads, medical science, bandages, etc., can solve the problems of waste of resources, environmental pollution, loss, etc., and achieve the effect of being difficult to control, expanding the scope of use, and easy to swell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

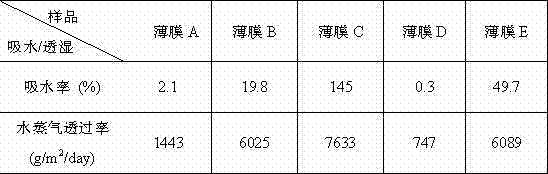

Examples

Embodiment 1

[0022] (1) Preparation of polyurethane solution: Mix 9 g of aliphatic polyurethane with 16.7 g of N,N-dimethylformamide solvent, and keep stirring in a water bath at 40 °C until completely dissolved to obtain a polyurethane solution with a concentration of 35%.

[0023] (2) Preparation of sericin suspension: Disperse 1 g of sericin particles in 6.6 g of N,N-dimethylformamide solvent and stir for a period of time to obtain a uniformly dispersed sericin suspension;

[0024] (3) Configuration of polyurethane / sericin blend solution: Add the sericin suspension obtained in (2) above into the polyurethane solution in (1) above, and stir at high speed for 30 minutes to obtain a uniformly mixed film-making solution, in which sericin Protein content is 3 wt%;

[0025] (4) Dry film formation: Pour a certain volume of film-forming solution onto the glassine paper, control a certain force and speed with a smear stick, coat the film evenly, and then put it in an oven at 70 °C for 5 minutes ...

Embodiment 2

[0027] (1) Preparation of polyurethane solution: Mix 7 g of medical polyurethane with 10.5 g of N,N-dimethylformamide solvent, and keep stirring in a water bath at 50 °C until completely dissolved to obtain a polyurethane solution with a concentration of 40%;

[0028] (2) Preparation of sericin suspension: Disperse 3 g of sericin particles in 12.8 g of N,N-dimethylformamide solvent and stir for a period of time to obtain a uniformly dispersed sericin suspension;

[0029] (3) Configuration of polyurethane / sericin blend solution: Add the sericin suspension obtained in (2) above into the polyurethane solution in (1) above, and stir at high speed for 30 minutes to obtain a uniformly mixed film-making solution, in which sericin The protein content is 9 wt%;

[0030] (4) Dry film formation: Pour a certain volume of film-forming solution onto the glassine paper, control a certain force and speed with a smear stick, coat the film evenly, and then put it in an oven at 30 °C for 30 minu...

Embodiment 3

[0032] (1) Preparation of polyurethane solution: Mix 5 g of medical polyurethane with 6.1 g of N,N-dimethylformamide solvent, and keep stirring in a water bath at 60 °C until completely dissolved to obtain a polyurethane solution with a concentration of 45%;

[0033] (2) Preparation of sericin suspension: Disperse 5 g of sericin particles in 17.2 g of N,N-dimethylformamide solvent and stir for a period of time to obtain a uniformly dispersed sericin suspension;

[0034] (3) Configuration of polyurethane / sericin blend solution: Add the sericin suspension obtained in (2) above into the polyurethane solution in (1) above, and stir at high speed for 30 minutes to obtain a uniformly mixed film-making solution, in which sericin The protein content is 15 wt%;

[0035] (4) Wet film formation: Pour a certain volume of film-making liquid onto glassine paper, control a certain force and speed with a smear stick, coat the film evenly, and then immerse in a certain volume of clear water to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water vapor transmission rate | aaaaa | aaaaa |

| Water vapor transmission rate | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com