Thermal-reversible self-repair polyurethane membrane and preparation method therefor

A polyurethane film and self-healing technology, which is applied in the field of self-healing polymer-based composite materials and its preparation, can solve the problems of low hardness and low heat-resistant temperature, and achieve high self-healing ability, good manufacturability, and good environmental protection characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

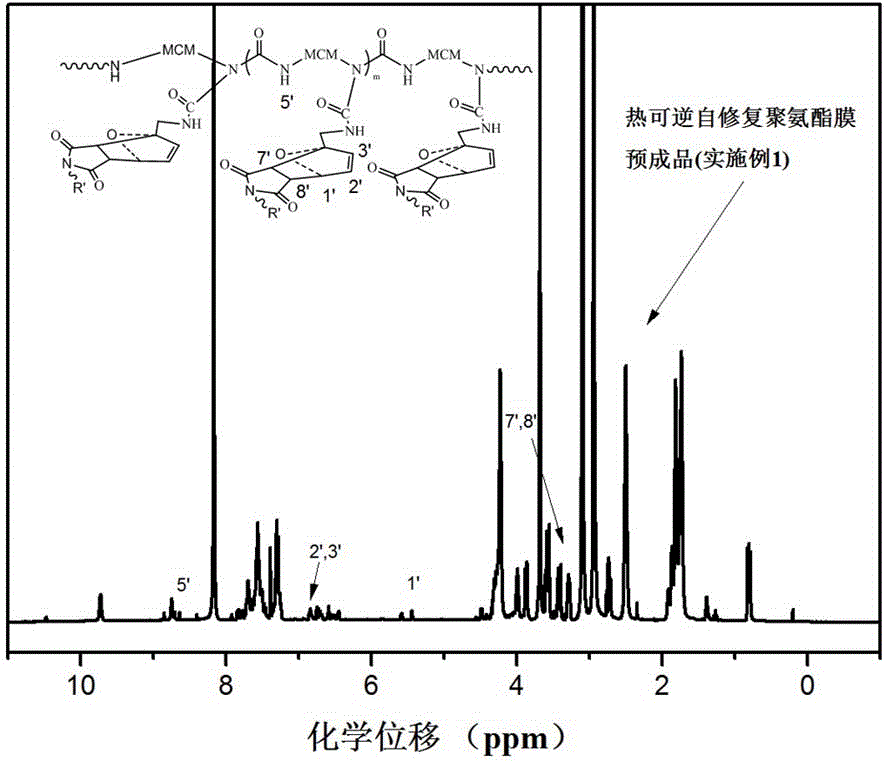

Embodiment 1

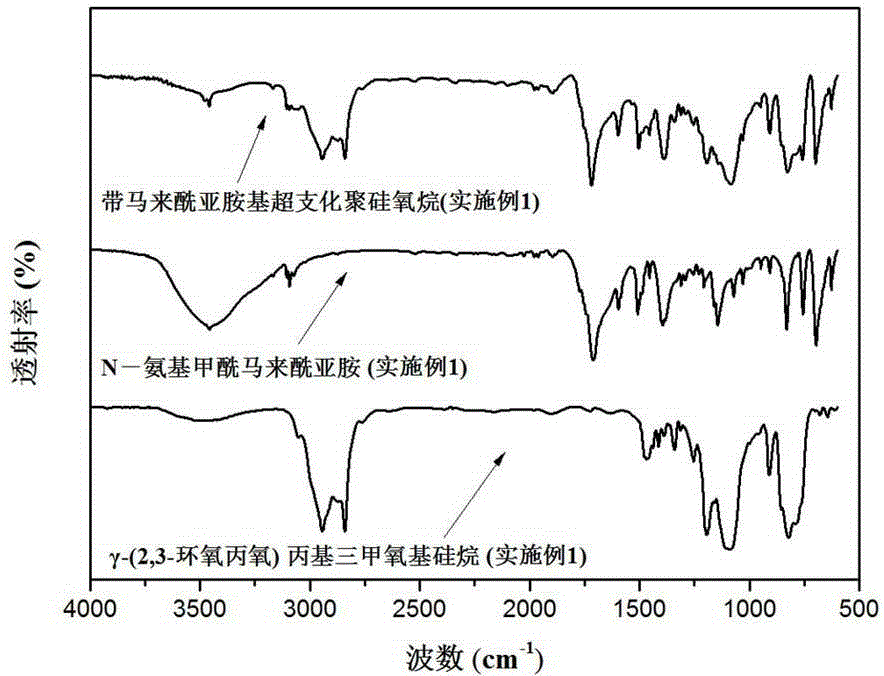

[0035] (1) Preparation of hyperbranched polysiloxane with maleimide group

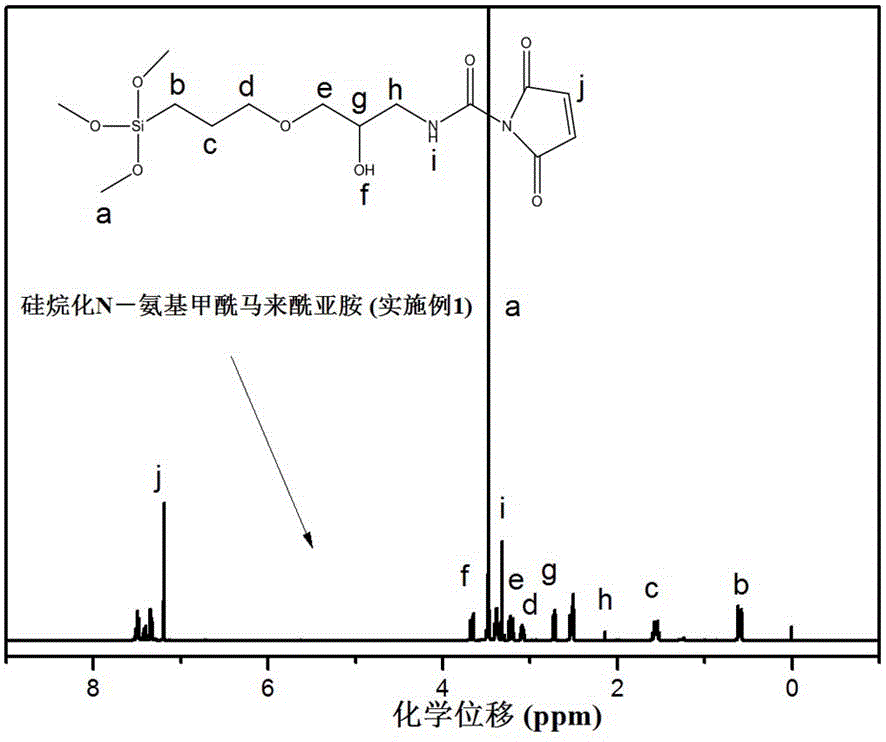

[0036] in N 2 Under protection and magnetic stirring conditions, in a 250mL three-necked flask, 2.24g N-carbamoylmaleimide and 100mL toluene were fully mixed; then 3.584g γ-(2,3-epoxypropylene oxy)propyltrimethoxysilane. After the dropwise addition, the temperature of the three-neck flask was raised to 50° C. and the reaction was carried out at constant temperature for 6 hours. After the reaction was over, the solvent was distilled off under reduced pressure, and vacuum-dried at room temperature to obtain silanized N-carbamoylmaleimide. For its hydrogen nuclear magnetic resonance spectrum, refer to the attached figure 1 .

[0037] Add 0.2688g of deionized water, 80mL of ethanol and 0.009g of tetramethylammonium hydroxide to the silylated N-carbamoylmaleimide, and mix thoroughly under the condition of magnetic stirring. Raise the temperature to 50°C and react at a constant temperature for 3 hours; ...

Embodiment 2

[0054] (1) Preparation of hyperbranched polysiloxane with maleimide group

[0055] in N 2Under protection and stirring conditions, in a 250mL three-necked flask, 2.24g N-carbamoylmaleimide and 80mL toluene were fully mixed; then 4.256g γ-(2,3-glycidyloxypropoxy ) Propyltrimethoxysilane. After the dropwise addition was completed, the temperature of the three-neck flask was raised to 55° C. and the reaction was carried out at constant temperature for 7 hours. After the reaction was completed, the solvent was distilled off under reduced pressure, and vacuum-dried at room temperature to obtain silylated N-carbamoylmaleimide.

[0056] To silylated N-carbamoylmaleimide, add 0.448g deionized water, 90mL ethanol, methanol, propanol, n-butanol mixture and 0.009g tetramethylammonium hydroxide, and under the condition of mechanical stirring , mix well. Raise the temperature to 50° C. and react at a constant temperature for 5 hours; after the reaction, the solvent was distilled off un...

Embodiment 3

[0063] (1) Preparation of hyperbranched polysiloxane with maleimide group

[0064] in N 2 Under protection and stirring conditions, in a 250mL three-necked flask, 2.24g N-carbamoylmaleimide and 90mL toluene were fully mixed; then 3.607g γ-(2,3-glycidyloxypropoxy ) Propyltrimethoxysilane. After the dropwise addition, the temperature of the three-neck flask was raised to 60° C. and the reaction was carried out at constant temperature for 6 hours. After the reaction was completed, the solvent was distilled off under reduced pressure, and vacuum-dried at 45° C. to obtain silylated N-carbamoylmaleimide.

[0065] Add 0.2748g of deionized water, 80mL of ethanol and 0.0091g of tetramethylammonium hydroxide and tetraethylammonium hydroxide mixture to the silylated N-carbamoylmaleimide, and under magnetic stirring conditions, fully mix. Raise the temperature to 55° C. and react at a constant temperature for 4 hours; after the reaction, the solvent was distilled off under reduced p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com