Application of function polyol to preparation of multifunctional polyurethane

A polyol, polyurethane technology, applied in and a functional polyol in the field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

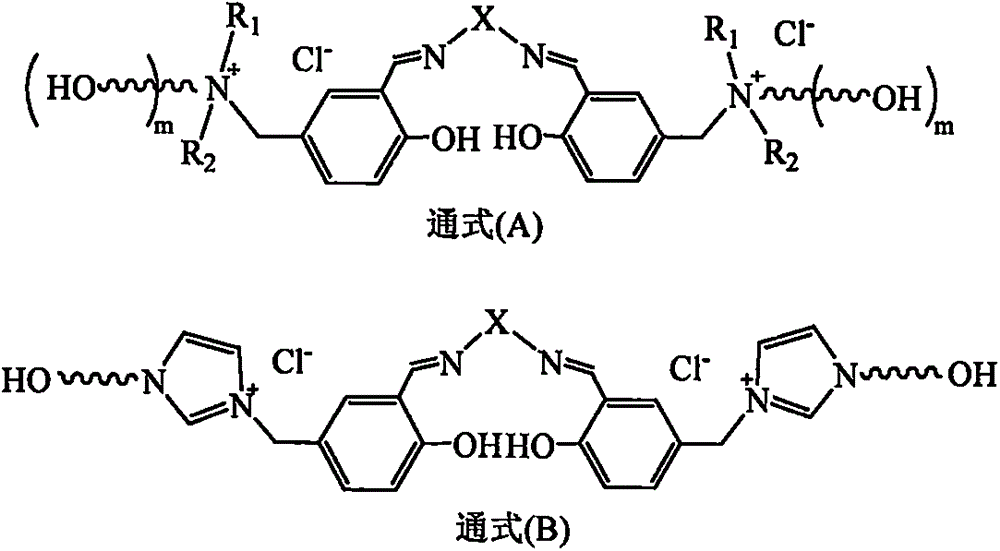

Method used

Image

Examples

Embodiment 1

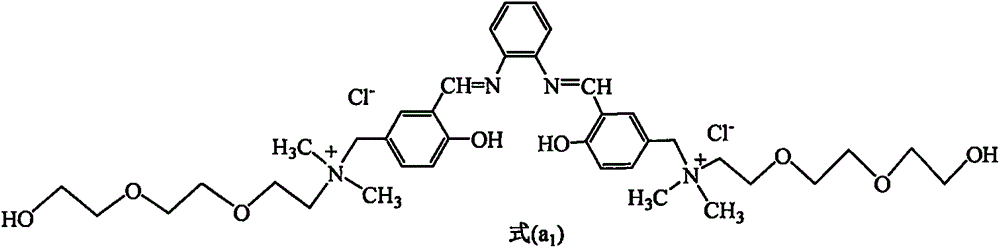

[0022] Weighing formula (a 1 38 grams of polyols containing quaternary ammonium cations and Salophen functional groups of the structure shown in ), 62 grams of polyether triols with a hydroxyl value of 56 mgKOH / g and an average molecular weight of 3000 to 4000 and 1,4-dioxane 12 gram and mix evenly, then add 0.5 grams of dibutyltin dilaurate, 0.5 grams of triethylenediamine, 25 grams of pentane and 4.2 grams of deionized water, and stir well; finally add 1.3 grams of AK6618 silicone foam stabilizer and 63 grams of diphenylmethane diisocyanate, stirred rapidly and mixed evenly, foamed at room temperature in a foaming box, and aged for 2 hours to obtain an orange multifunctional polyurethane foam material containing quaternary ammonium cations and Salophen functional groups.

[0023] where formula (a 1 ) the structural formula of the polyhydric alcohol containing quaternary ammonium cation and Salophen functional group:

[0024]

[0025] Performance test: The soft foam dens...

Embodiment 2

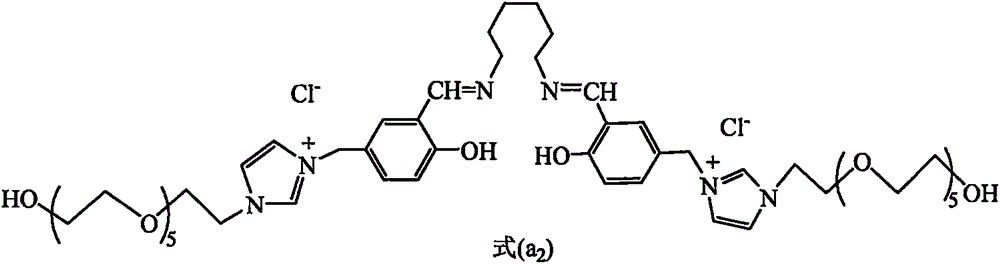

[0030] According to the method and operation steps of embodiment 1, the formula (a in embodiment step one) 1 The polyalcohol containing quaternary ammonium cation and Salen functional group of the structure shown in ) is replaced by formula (a 2 ) of the structure shown in the polyhydric alcohol containing quaternary ammonium cation and Salen functional group, prepared to contain quaternary ammonium cation and Salen functional group functional polyurethane soft foam material, its density is 0.90g / cm after measuring 3 , Absorption rate of normal saline is 126.

[0031] where formula (a 2 ) contains the structural formula of quaternary ammonium cation and Salen functional group polyol:

[0032]

Embodiment 3

[0034] Weighing formula (a 1 ) 43 grams of polyols containing quaternary ammonium cations and Salophen functional groups, 57 grams of polyether triols with a hydroxyl value of 56 mgKOH / g and an average molecular weight of 3000 to 4000, 1,4-dioxane 50 gram, 50 grams of chlorobenzene, 0.5 grams of dibutyltin dilaurate, 0.5 grams of triethylenediamine and 0.8 grams of deionized water. After fully stirring, add 56 grams of toluene diisocyanate, stir quickly and mix evenly, and mature at 100 ° C After 2 hours, after washing with ethanol and drying, a light yellow multifunctional polyurethane porous resin material containing quaternary ammonium cations and Salophen functional groups was obtained.

[0035] The performance test is based on the method for measuring the exchange capacity of cation exchange resins in GB / T8144-2008. Cu 2+ The exchange capacity is 0.2883mmol / g, and it adsorbs Cu 2+ Then it turns light green.

[0036] where formula (a 1 ) the structural formula of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com