Biodegradable resin material applied to oil and gas fields and preparation method for biodegradable resin material

A technology for degrading resins, oil and gas fields, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of insufficient water production, formation damage, long contact time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

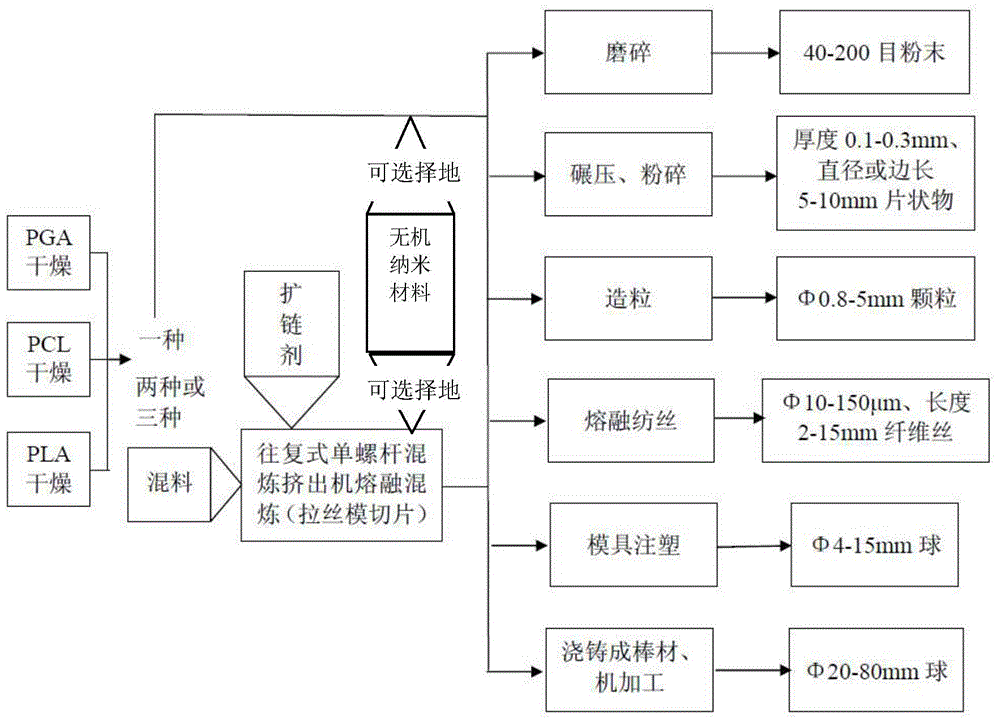

[0041] This embodiment provides a degradable resin material applied to oil and gas fields, such as figure 1 As shown, it is prepared by the following steps:

[0042] (1) Stir and dry polycaprolactone slices with a weight average molecular weight (Mw) of 80,000 at 50-55°C and a vacuum of 90 kPa for 12 hours; The acetic acid slices were stirred and dried for 4 hours at 100-105°C and a vacuum of 90 kPa; hours, make its moisture content lower than 0.1wt%, the best lower than 0.01wt%;

[0043] (2) Take 100 kilograms of polycaprolactone slices, 750 kilograms of polyglycolic acid slices and 150 kilograms of polylactic acid slices after removing water and add them to a stainless steel mixer with a stirring device, heat up to 50 ° C, and At a temperature of 90 kPa, mix for 10 minutes;

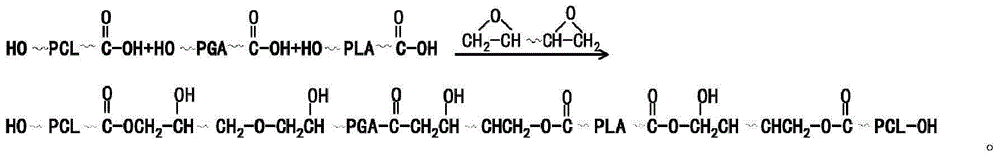

[0044] (3) Add the mixture of polyglycolic acid, polycaprolactone and polylactic acid in the mixer to the reciprocating single-screw mixing extruder, add 3.5 kilograms of silicon dioxide with a parti...

Embodiment 2

[0049] The PGA / PCL / PLA resin nano-alloy slices prepared in Example 1 are granulated through a screw granulator at 200°C, the particle diameter is Φ1-1.5 mm, and the temperature is dropped to At 20°C, molded Φ1-1.5 mm particles are obtained, and a granular degradable resin material is obtained.

[0050] The Φ1-1.5 mm granular degradable resin material is used in Well C1 (in the well depth of 6513-6572m, the temperature of this well section is 152°C-153°C, two layers are opened, 6513-6524m and 6561-6572m) well temporarily For plugging and diverting fracturing operations, use guar gum jelly fracturing fluid to carry, and divide into one temporary plugging and diverting fracturing, use the Φ1-1.5 mm particle temporary plugging material 268 kg, after diverting, under the same pump injection displacement, the pressure rises The height is 15.2MPa, and the diversion effect of temporary plugging is obvious. The granular temporary plugging material is completely degraded at 150°C for 12...

Embodiment 3

[0052] This embodiment provides a degradable resin material applied to oil and gas fields, such as figure 1 As shown, it is prepared by the following steps:

[0053] (1) Stir and dry polycaprolactone chips with a weight average molecular weight (Mw) of 20,000 at 50-55°C and a vacuum of 90 kPa for 11 hours; The acetic acid slices were stirred and dried for 4 hours at 95-100°C and a vacuum of 90 kPa; the moisture content was lower than 0.1wt%, preferably lower than 0.01wt%;

[0054] (2) Get 500 kilograms of polycaprolactone slices and 500 kilograms of polyglycolic acid slices after the above water removal and add them to a stainless steel mixer with a stirring device, heat up to 45 ° C, and under a vacuum of 90 kPa, Mix for 10 minutes;

[0055] (3) Add the mixture of polyglycolic acid and polycaprolactone in the mixer to the reciprocating single-screw mixing extruder, add 5 kg of silicon dioxide with a particle diameter of 10-20nm, and add 1.3 kg The chain extender ADR-4300 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com