Preparation method of hetero-atom-doped graphyne

A technology of graphyne and doping elements, which is applied in the field of preparation of doped nanomaterials, to achieve the effects of easy control of the reaction process, change of chemical properties, and easy promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

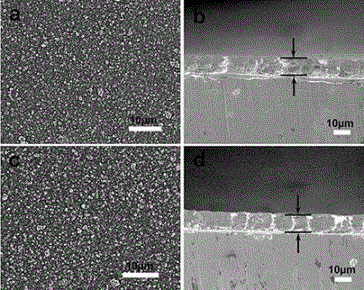

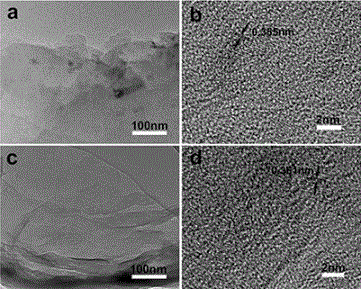

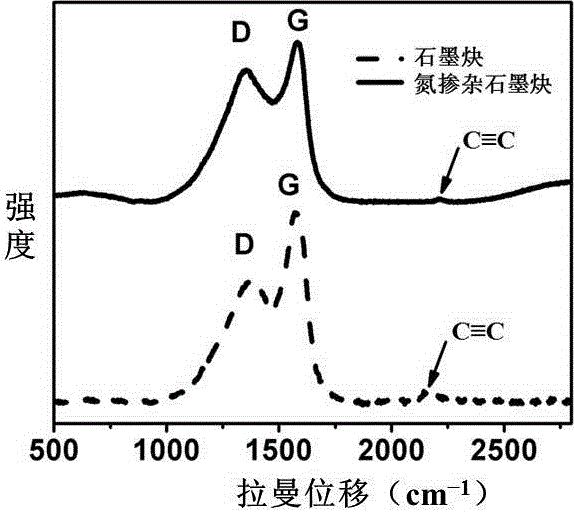

Embodiment 1

[0018] Dry 100mg of graphyne powder and place it in a porcelain boat, then place the porcelain boat in the middle of a clean quartz tube, put the quartz tube into a temperature-programmed tube furnace, and make the middle of the quartz tube in the temperature-programmed tube furnace Vacuumize the central area of the center area, feed nitrogen, start the temperature program, rise to 500 ° C, feed ammonia in the nitrogen as a nitrogen source, and the doping reaction begins. After 6 hours of reaction, stop feeding ammonia, and the program is terminated. Continue cooling to room temperature with nitrogen gas.

Embodiment 2

[0020] Dry the graphdiyne film grown on the copper substrate, place it in a porcelain boat, then place the porcelain boat in the middle of a clean quartz tube, put the quartz tube into a temperature-programmed tube furnace, so that the middle of the quartz tube is at In the central area of the temperature-programmed tube furnace, vacuumize, feed nitrogen, start the temperature program, rise to 500°C, feed ammonia in the nitrogen as the nitrogen source, and the doping reaction begins. After 6 hours of reaction, stop feeding ammonia gas, the program was terminated, and nitrogen gas was continued to cool to room temperature.

Embodiment 3

[0022] Dry 100mg of graphyne powder and place it in a porcelain boat, then place the porcelain boat in the middle of a clean quartz tube, put the quartz tube into a temperature-programmed tube furnace, and make the middle of the quartz tube in the temperature-programmed tube furnace Vacuumize the central area, feed nitrogen, start the temperature program, rise to 600 ° C, feed ammonia in the nitrogen as a nitrogen source, and the doping reaction begins. After 6 hours of reaction, stop feeding ammonia, and the program is terminated. Continue cooling to room temperature with nitrogen gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com