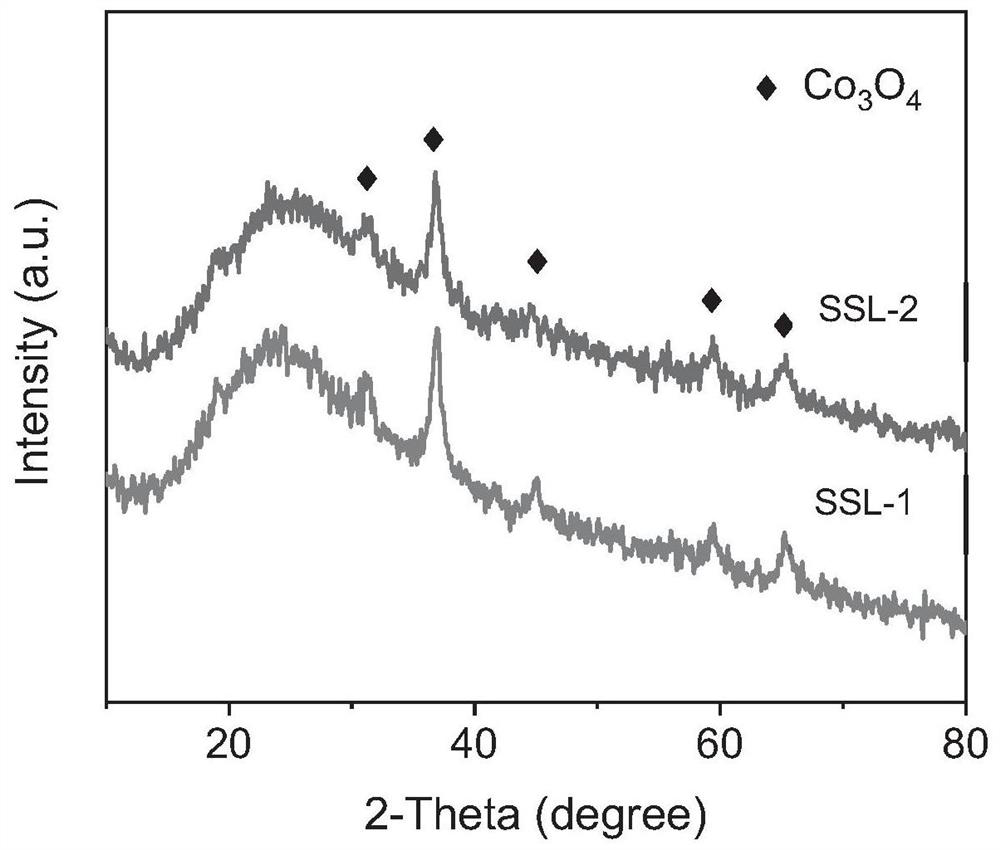

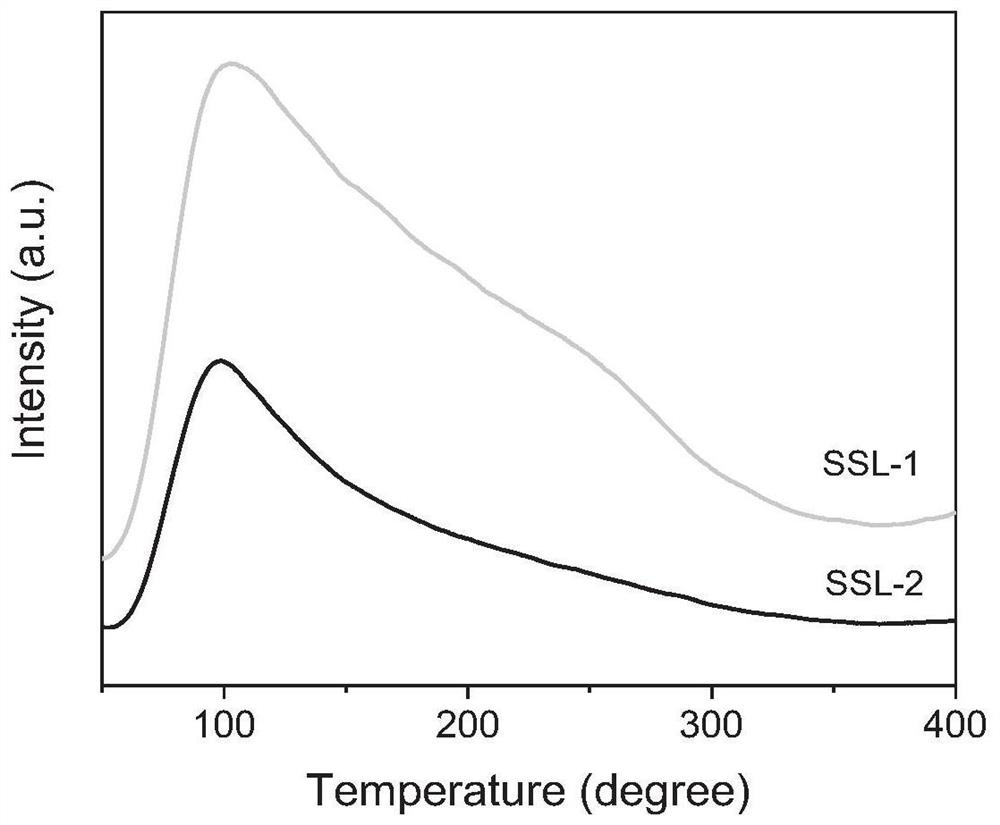

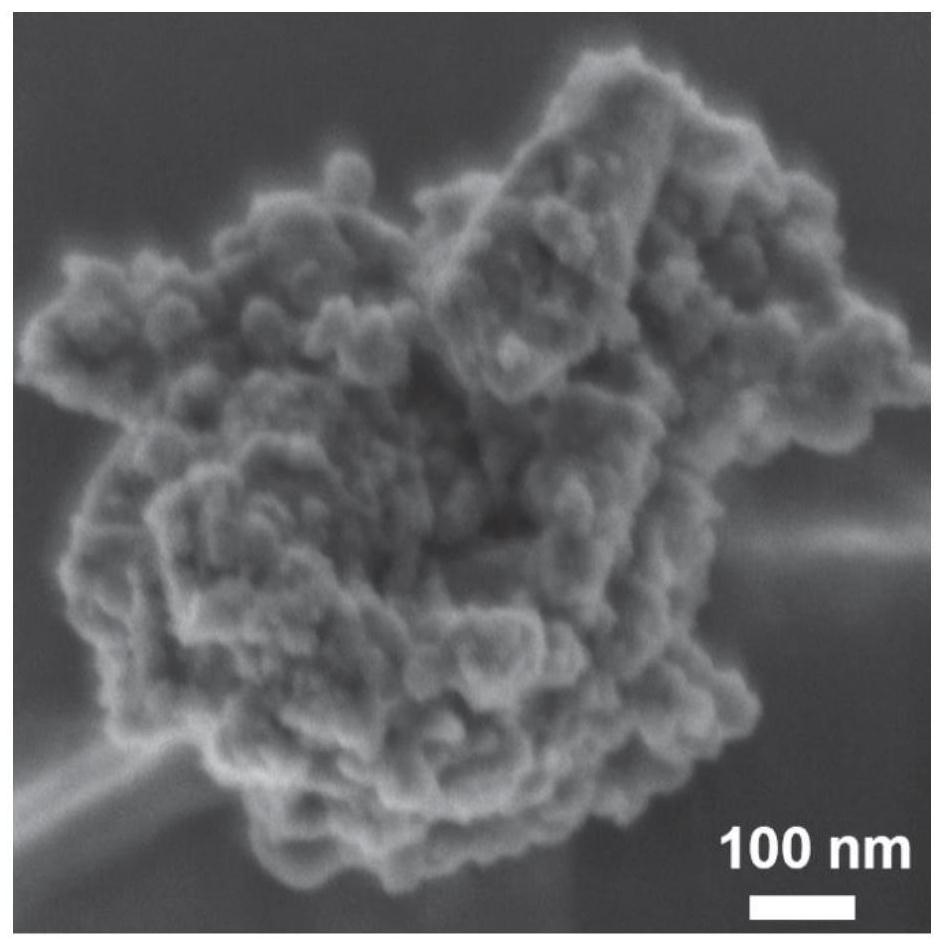

Zirconium-modified amorphous mesoporous SiO2-supported cobalt-based Fischer-Tropsch catalyst and preparation method thereof

A catalyst, cobalt-based technology, applied in the field of catalysis, can solve the problems of low conversion rate of CO, lack of transition metal additives, low specific surface area of the carrier, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] One-pot method: Weigh 1.8g of zirconium isopropoxide and 21.2g of ethyl orthosilicate and fully dissolve them in a plastic beaker, wherein the molar ratio of Si to Zr is 25, stir for 20 minutes to fully dissolve and mix evenly, called mixing liquid armor. 15.3g of triethanolamine and 11.5g of deionized water were mixed and stirred for 30 minutes to make them fully stirred evenly, which was called mixed solution B. Add the mixed solution B dropwise to the mixed solution A, and stir for more than 20min to make it fully mixed. Finally, 21.8g of tetramethylammonium hydroxide was added dropwise into the mixed solution prepared in the previous step, and stirred thoroughly until gelling. The gelled solid was transferred to a watch glass, dried in an oven at 60°C for 12 hours, and then transferred to a vacuum oven at 60°C for 12 hours. The obtained solid was transferred to a polytetrafluoroethylene hydrothermal kettle, hydrothermally treated at 180°C for 3h, and then transfer...

Embodiment 2

[0052] One-pot method: Weigh 0.23g of zirconyl nitrate and 21.2g of ethyl orthosilicate and fully dissolve them in a plastic beaker, wherein the molar ratio of Si to Zr is 100, stir for 20 minutes to fully dissolve and mix evenly, called a mixed solution First. 17.2g of trimethylamine and 13.2g of deionized water were mixed and stirred for 90 minutes to make them fully stirred evenly, which was called mixed solution B. Add the mixed solution B to the mixed solution A dropwise, and stir for more than 20 minutes to fully mix to obtain the mixed solution C. Finally, 21.8 g of tetramethylammonium hydroxide was added dropwise into the mixed solution C, and stirred thoroughly until gelling. The gelled solid was transferred to a watch glass, dried in an oven at 80°C for 12 hours, and then transferred to a vacuum oven at 80°C for 12 hours. The obtained solid was transferred to a polytetrafluoroethylene hydrothermal kettle, hydrothermally treated at 200°C for 2h, and then transferred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com