Abandoned liquid crystal display panel shear crusher

A liquid crystal panel and crusher technology, which is applied in grain processing and other directions, can solve the problems of large-scale, industrialization, high-efficiency recycling of liquid crystal panels, and the inability to meet the recycling needs of liquid crystal panels, and achieves small meshing area, less heat, and friction. short distance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

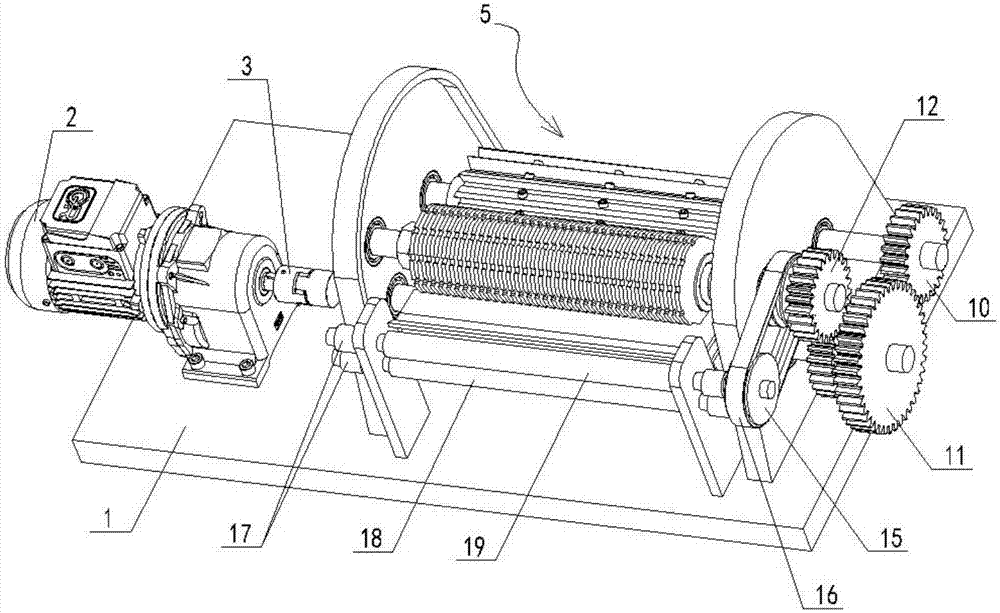

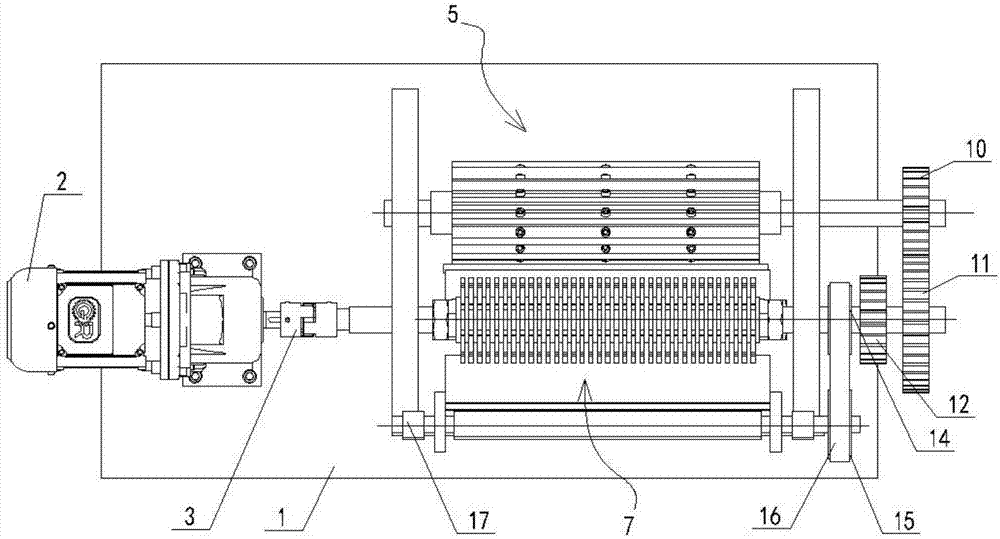

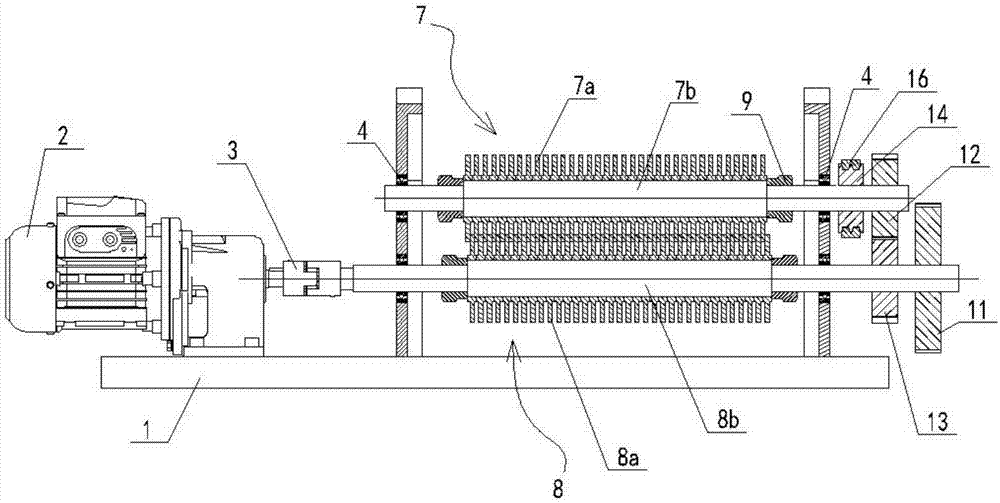

[0030]The shearing and shredding machine for waste liquid crystal panels in this embodiment includes a biaxial shearing mechanism, a rotary cutting mechanism and a feeding mechanism.

[0031] like figure 1 and image 3 As shown, the biaxial shearing mechanism has a lower cutter shaft 8b and an upper cutter shaft 7b arranged in parallel, and the lower cutter shaft 8b and the upper cutter shaft 7b are supported by a support plate and a rolling bearing 4 arranged on the support plate; The output shaft of the output shaft is directly connected with the lower cutter shaft 8b through the coupling 3, and is used to drive the rotation of the lower cutter shaft 8b; the lower cutter shaft 8b and the upper cutter shaft 7b realize gear transmission through a pair of meshing gears, and the pair of meshing gears are respectively The lower cutter shaft inner gear 13 fixedly arranged on the shaft end of the lower cutter shaft 8b, and the upper cutter shaft gear 12 fixedly arranged on the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com