Lithium-rich manganese-based cathode material coated with composite carbon material and preparation method thereof, and lithium battery

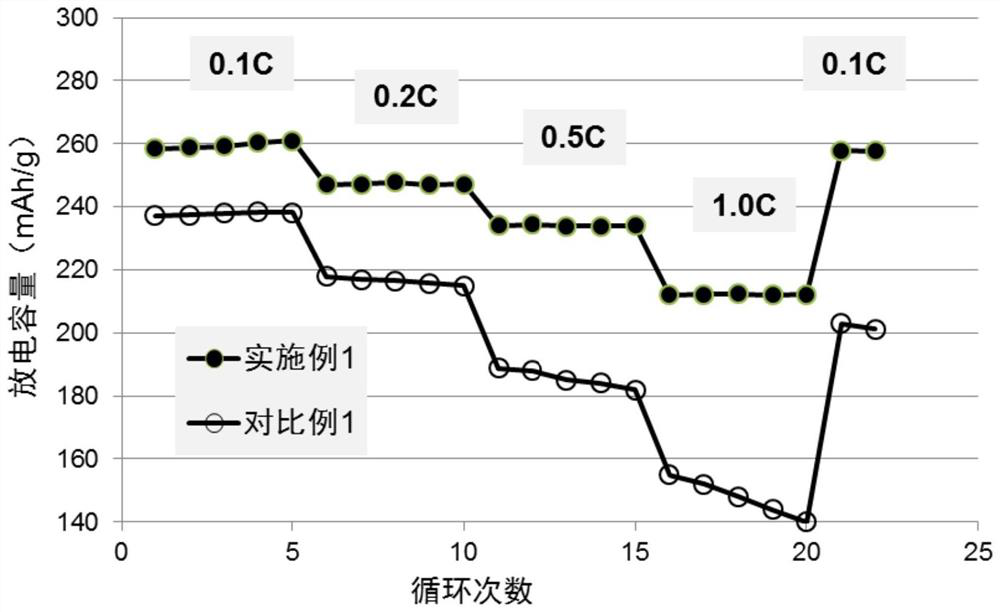

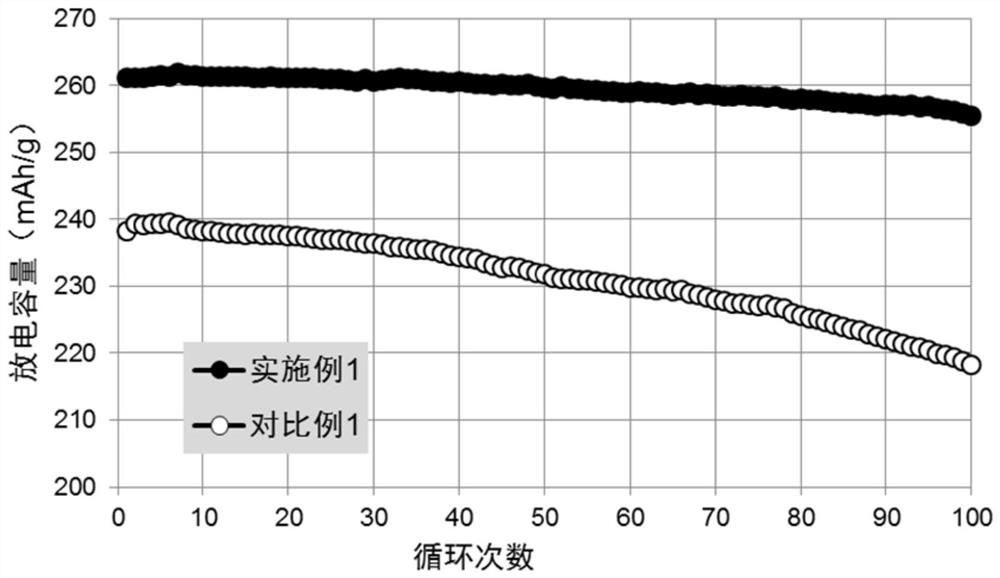

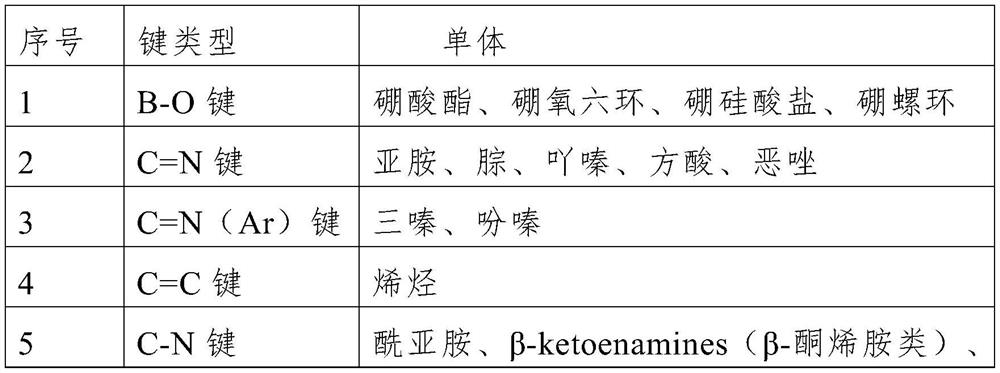

A lithium-rich manganese-based, positive electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor stability, small specific surface area, material conductivity, battery rate performance, and cycle stability. To achieve the effect of improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a method for preparing a lithium-rich manganese-based positive electrode material coated with a composite carbon material, comprising the following steps:

[0046] S01, preparing a lithium-rich manganese-based positive electrode material, specifically including the following sub-steps:

[0047] a1. Preparation of lithium-rich manganese-based precursor by carbonate co-precipitation method, the chemical formula is Mn 0.54 Ni 0.13 co 0.13 (CO 3 ) 0.8 . Specifically, it is prepared by mixing soluble manganese salt, soluble nickel salt and soluble cobalt salt to form a mixed salt solution, then adding carbonate solution as a precipitating agent, adding a complexing agent at the same time, and finally carrying out co-precipitation reaction. For the specific process, please refer to the existing steps of the carbonate co-precipitation method, which will not be repeated here.

[0048] a2. Mix the lithium-rich manganese-based precursor and lithium ...

Embodiment 2

[0076] This embodiment provides a method for preparing a lithium-rich manganese-based positive electrode material coated with a composite carbon material, comprising the following steps:

[0077] S01. Prepare a lithium-rich manganese-based cathode material.

[0078] Specifically, the chemical formula is 0.5Li 2 MnO 3 0.5LiNi 0.5 co 0.2 mn 0.3 o 2 . Refer to Example 1 for the entire preparation process, the only difference is that in this example, when sintering in step a3, first raise the temperature to 400°C at a rate of 2°C / min, sinter for 6 hours, continue to heat up to 700°C, and sinter 20h. For other parameters, refer to Embodiment 1, which will not be repeated here.

[0079] S02. Prepare COFs materials. In this embodiment, PZ-COF-1 powder is prepared by solvothermal method, including the following sub-steps:

[0080] b1. Place 1,2,4,5-tetraaminobenzene (110.0mg, 1.0mmol) and hexahydroxytriphenylene (108.0mg, 1.0mmol) in a polytetrafluoroethylene-lined autoclave,...

Embodiment 3

[0087] This embodiment provides a method for preparing a lithium-rich manganese-based positive electrode material coated with a composite carbon material, comprising the following steps:

[0088] S01. Prepare a lithium-rich manganese-based cathode material.

[0089] Specifically, the chemical formula is 0.4Li 2 MnO 3 0.6LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 . Refer to Example 1 for the entire preparation process. The only difference is that in this example, when sintering in step a3, the temperature is raised to 450°C at a rate of 5°C / min, sintered for 3.5 hours, and then heated to 900°C. Sintering for 18h. For other parameters, refer to Embodiment 1, which will not be repeated here.

[0090] S02. Prepare COFs materials. In this embodiment, the solvothermal method is used to prepare COF-5 powder, including the following sub-steps:

[0091] b1. Put 1,4-benzenediboronic acid (BDBA; 185mg, 1.116mmol) and 2,3,6,7,10,11-hexahydroxytriphenylene (HHTP; 241.5mg, 0.745mmol) in polytetraflu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com