Lithium ion battery positive electrode material lithium iron manganese phosphate and liquid phase preparation method thereof

A lithium-ion battery, lithium iron manganese phosphate technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as structural instability, and achieve the effects of reducing battery costs, high discharge voltage platform, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A liquid phase preparation method of lithium iron manganese phosphate lithium ion battery cathode material, characterized in that: the steps are as follows: (1) synthesis of precursor: iron salt weighed according to molar ratio 1-x:x:1.0-2.0, Manganese salt, oxalate, iron salt, manganese salt and antioxidant are made into solution A, oxalate is made into solution B, and ammonia water is made into solution C; measure B solution as the bottom liquid and pour it into a four-neck flask; A and solution C are added dropwise in parallel, after solution A and solution C are added dropwise, stir for 10-60min, then dropwise add solution B; stir and age for 3-6h, then stand and age for 10-15h; filter, wash, After vacuum drying at 50°C, the ferromanganese oxalate precipitation precursor was obtained;

[0024] (2) Ingredients: Weigh 10-15% of the carbon source, add it to a ball mill tank, dissolve it in a quantitative solvent, then add lithium source, precursor, and phosphorus sourc...

Embodiment 1

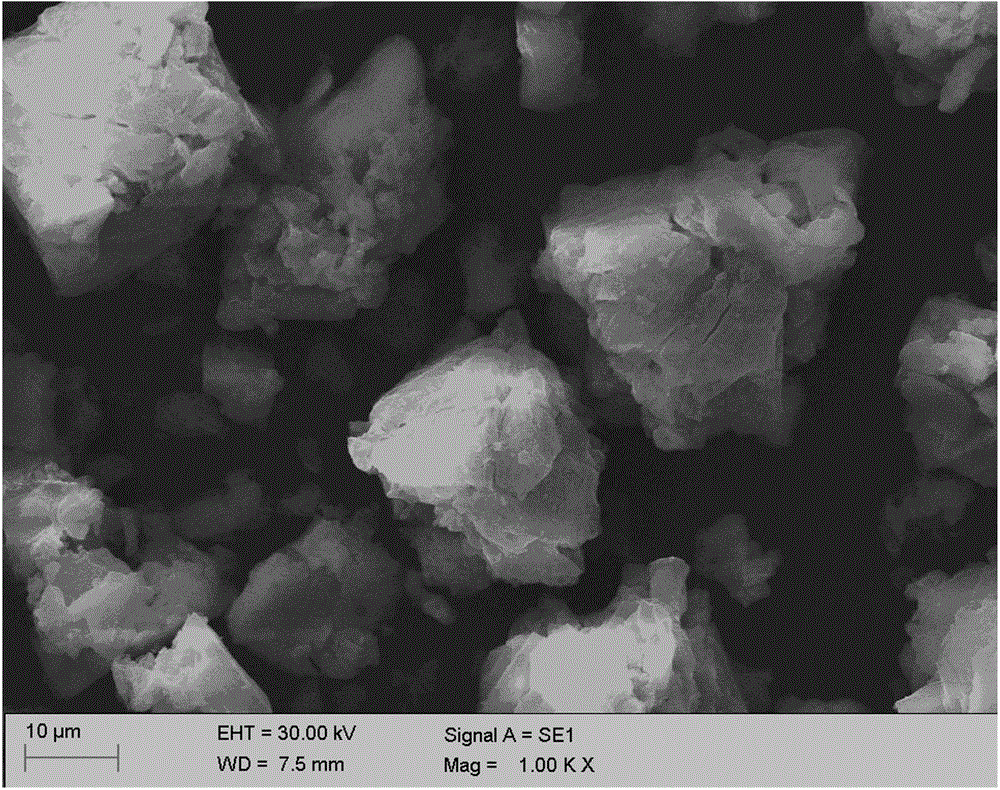

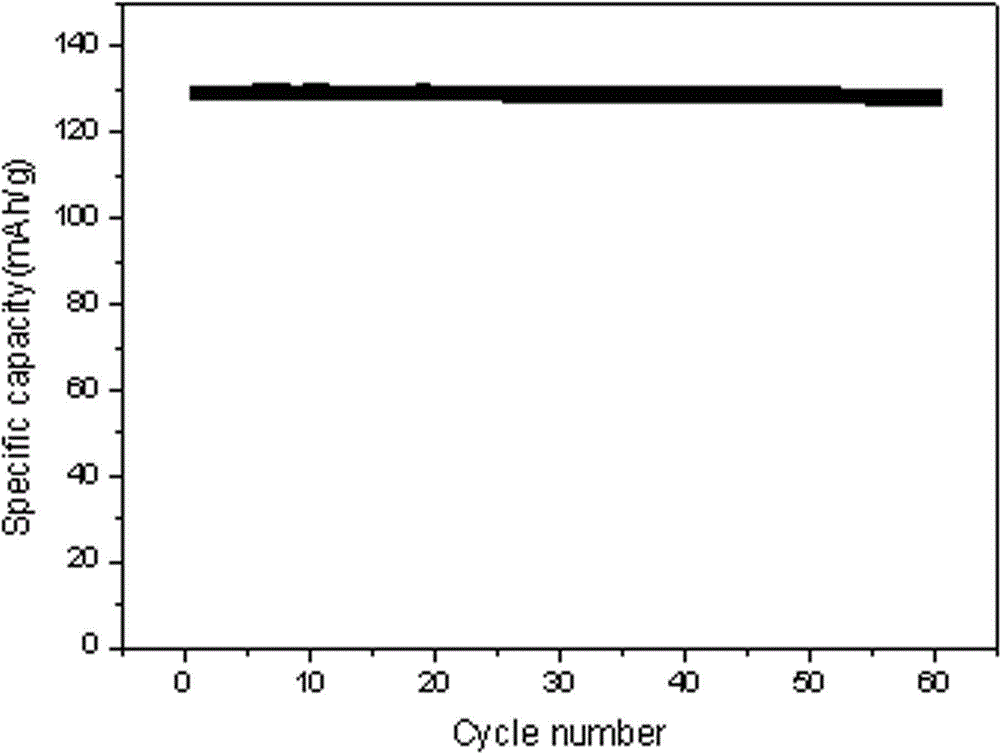

[0035] Weigh a certain amount of ferrous sulfate, manganese sulfate, and ascorbic acid in a molar ratio of 1:1:0.1 and dissolve them in 60ml of distilled water to make a 1M solution A; Take 200mL of distilled water as solution B; measure 45mL of 2M ammonia solution as solution C; take 67mL of B solution and pour it into a four-necked flask as the bottom solution, and drop solution A and solution C into the four-necked flask in parallel, and control the dripping Acceleration is 5 seconds / drop, after the dropwise addition, stir for 10 minutes, then add solution B dropwise, control the dropping speed to 3 seconds / drop, stir for 4 hours after the dropwise addition, let stand and age for 15 hours, suction filter, wash, 50 ℃ Vacuum-dried to obtain the oxalate co-precipitation precursor, the specific morphology is shown in the scanning electron microscope image, see the attached figure 1 ;According to the molar ratio of lithium source: precursor: phosphorus source: carbon source = 1....

Embodiment 2

[0038] Weigh a certain amount of ferrous chloride, manganous acetate, and ascorbic acid in a molar ratio of 3:2:0.1 and dissolve them in 60ml of distilled water to make a 1M solution A; Dissolve ammonium in 200mL of distilled water as solution B; measure 45mL of 2M ammonia solution as solution C; take 67mL of solution B and pour it into a four-necked flask as the bottom solution, and pour solution A and solution C into the four-necked flask in parallel, Control the rate of addition to be 5 seconds / drop, complete the dropwise addition and stir for 10 min, then add solution B dropwise, control the rate of addition to be 3 seconds / drop, stir for 4 hours after the completion of the dropwise addition, leave to stand for aging for 15 hours, suction filtration, washing, Vacuum drying at 50°C to obtain the oxalate co-precipitation precursor; according to the molar ratio of lithium source: precursor: phosphorus source: carbon source = 1.03:1:1:0.12, weigh the oxalate co-precipitation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com