Lithium ion battery positive electrode material and preparation method thereof

A lithium-ion battery and cathode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low safety performance, and achieve the effect of uniform size and excellent electrochemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The present invention also provides a method for preparing the above-mentioned positive electrode material, which method comprises dissolving cobalt salt and phosphate in an alcohol-containing aqueous solution to form a composite solution, adding the solution containing lithium salt dropwise to the stirring composite solution, and heating react to obtain a precursor, and heat and sinter the precursor in an inert atmosphere to obtain the positive electrode material.

[0015] In order to prevent the lithium cobalt phosphate particles from being oxidized during the sintering process, the precursor is heated and sintered in an inert atmosphere to obtain the positive electrode material. The inert atmosphere refers to any gas or gas that does not chemically react with the reactants and products. Gas mixture, such as nitrogen, one or more of the zero-group gases in the periodic table of elements. The inert atmosphere may be a static atmosphere, preferably a flowing atmosphere ...

Embodiment 1

[0026] This embodiment illustrates preparation lithium cobalt phosphate material provided by the present invention and preparation method;

[0027] Mix 0.06 mol cobalt salt, 0.06 mol (NH 4 ) 3 PO 4 Dissolved in 110ml of alcohol-containing aqueous solution to form a composite solution, the alcohol-containing aqueous solution is a mixed solution of dipropylene glycol and water, wherein the volume ratio of dipropylene glycol and water is 10:1;

[0028] Dissolve 0.06 moles of LiOH in deionized water to form 10ml of a lithium salt solution;

[0029] Heat the composite solution to 200°C and keep it warm in a water bath. At the same time, drop the solution containing lithium salt into the stirring composite solution at 10 drops / minute, and reflux for 6 hours to obtain a precursor. The precursor is placed in a nitrogen atmosphere. Heating and sintering at 700°C for 10 hours to obtain the positive electrode material A1;

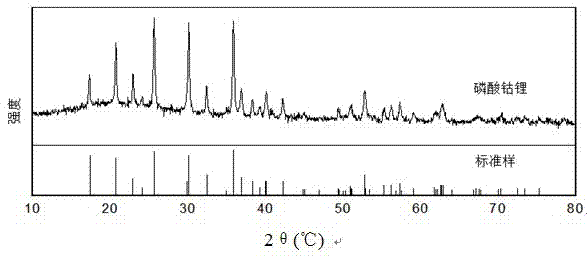

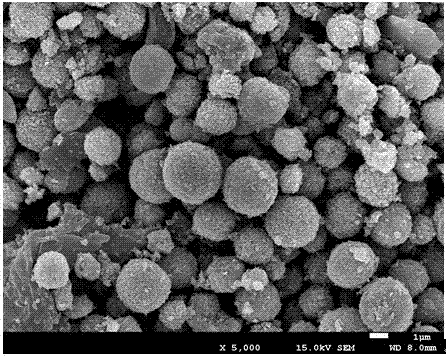

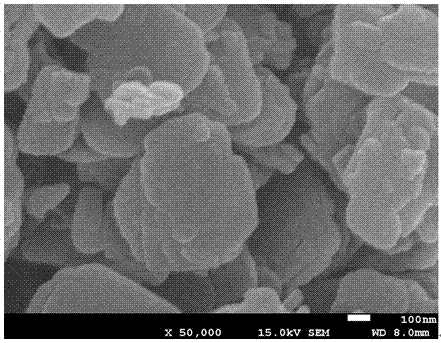

[0030] The XRD diffraction pattern of this material measured...

Embodiment 2

[0033] This embodiment illustrates preparation lithium cobalt phosphate material provided by the present invention and preparation method;

[0034] 0.06 mol cobalt salt, 0.06 mol NH 4 h 2 PO 4 Dissolved in 110ml of alcohol-containing aqueous solution to form a composite solution, the alcohol-containing aqueous solution is a mixed solution of diethylene glycol and water, wherein the volume ratio of diethylene glycol and water is 20:1;

[0035] 0.06 mol Li 2 CO 3 Dissolve in deionized water to form 10ml of a solution containing lithium salt;

[0036] Heat the composite solution to 150°C and keep it warm in a water bath. At the same time, add the solution containing lithium salt dropwise to the stirring composite solution at 10 drops / minute, and reflux for 6 hours to obtain a precursor. The precursor is placed in a nitrogen atmosphere. Heating and sintering at 800° C. for 9 hours to obtain the positive electrode material A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com