Zinc cathode material of nickel-zinc battery as well as preparation method and application of zinc cathode material

A nickel-zinc battery and zinc negative electrode technology, which is applied in the direction of nickel storage batteries, battery electrodes, alkaline storage batteries, etc., can solve the problems of poor cycle stability and material capacity of nickel-zinc batteries, so as to improve charge and discharge efficiency, improve poor cycle performance, reduce Effect of Zinc Negative Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of preparation method of nickel-zinc battery zinc negative electrode material, comprises the following steps:

[0027] Weigh 6.8775g of zinc sulfate heptahydrate and 0.5074g of ferric sulfate and dissolve them in 100mL of deionized water to form a salt solution; weigh 2.0946g of NaOH and 1.3294g of NaOH 2 CO 3 Dissolve in 100mL deionized water to make a precipitant; drop the above salt solution and precipitant into 10mL water at the same time, the titration rate of the salt solution and precipitant are both 1.5 mL / min, keep the reaction temperature at 60°C, use acid solution or alkali solution to maintain the pH value of the reaction solution at 10, and continue to stir; after the solution is completely titrated, keep stirring for 30 min, put it into a hydrothermal reaction kettle, and keep it at 120°C for 10 h; after suction filtration, washing and drying, the prepared It can be used as zinc anode material for nickel-zinc batteries.

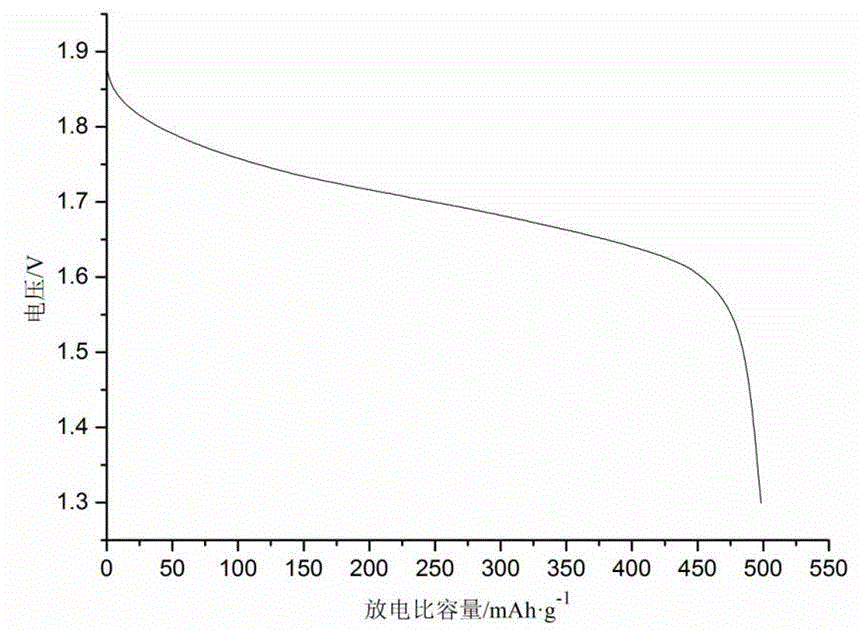

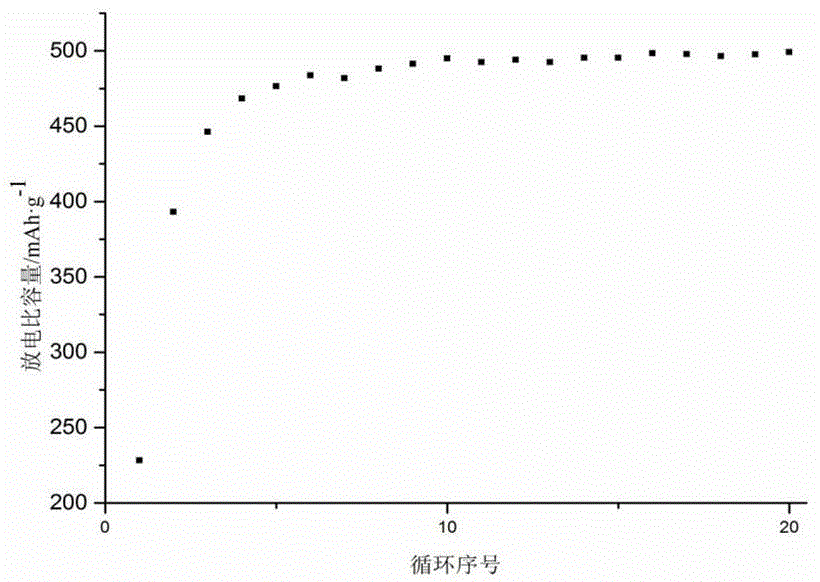

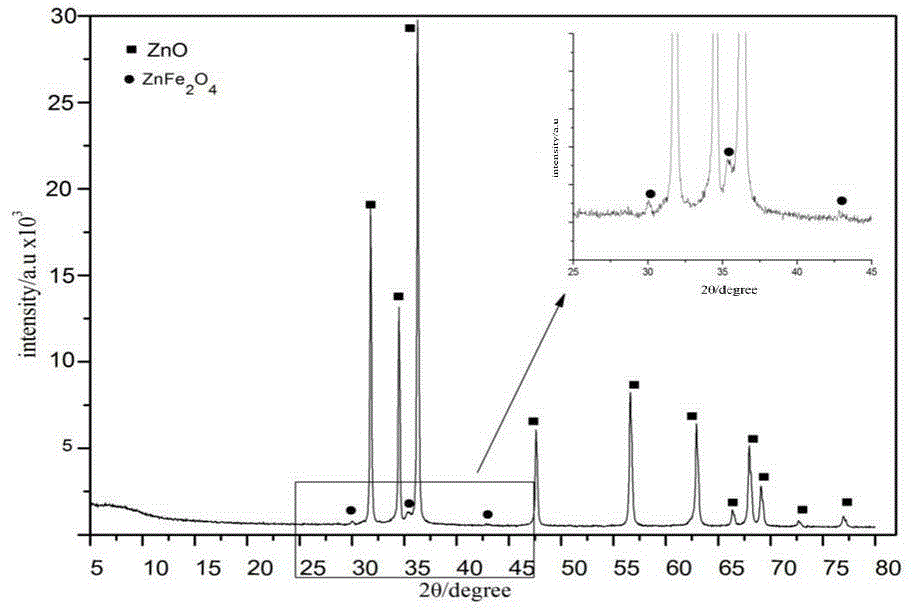

[0028] For ...

Embodiment 2

[0030] Embodiment 2: a kind of preparation method of nickel-zinc battery zinc negative electrode material, comprises the following steps:

[0031] Weigh 7.3621g zinc nitrate hexahydrate and 0.2040g ferric nitrate nonahydrate, dissolve in 100mL deionized water to make a salt solution; weigh 2.0740g NaOH and 1.3254g NaOH 2 CO 3 , dissolved in 100mL deionized water to make a precipitant; drop the above-mentioned salt solution and precipitant into 10 mL water at the same time, the titration rate of the salt solution and precipitant are both 1.5 mL / min, keep the reaction temperature at 60°C, and use acid solution or alkaline solution to help maintain the pH value of the reaction solution at 10, and keep stirring. After the titration of the solution is complete, keep stirring for 30 minutes, put it into a hydrothermal reaction kettle, and keep it at 110°C for 12 hours; after suction filtration, washing and drying, the material for the zinc negative electrode of the nickel-zinc batt...

Embodiment 3

[0036] Embodiment 3: a kind of preparation method of nickel-zinc battery zinc negative electrode material, comprises the following steps:

[0037] Weigh 3.3074g zinc chloride and 0.3752g ferric chloride hexahydrate, dissolve in 100mL deionized water to form a salt solution; weigh 2.0833g NaOH and 1.3275g NaOH 2 CO 3 , dissolved in 100mL deionized water to make a precipitant; drop the above salt solution and precipitant into 10mL water at the same time, the titration rate of both the salt solution and the precipitant is 1.5 mL / min, keep the reaction temperature at 70°C, and use acid solution Or an alkaline solution is used to assist in maintaining the pH value of the reaction solution at 12, and the stirring is continued. After the titration of the solution is complete, keep stirring for 60 min, put it into a hydrothermal reaction kettle, and keep it at 150°C for 8 h. Suction filtration, washing, and drying are used to obtain the material for the zinc negative electrode of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com