A kind of graphite-hard carbon coated material and preparation method thereof

A coating type, graphite technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of irreversible capacity decline, achieve the effect of improving poor cycle performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

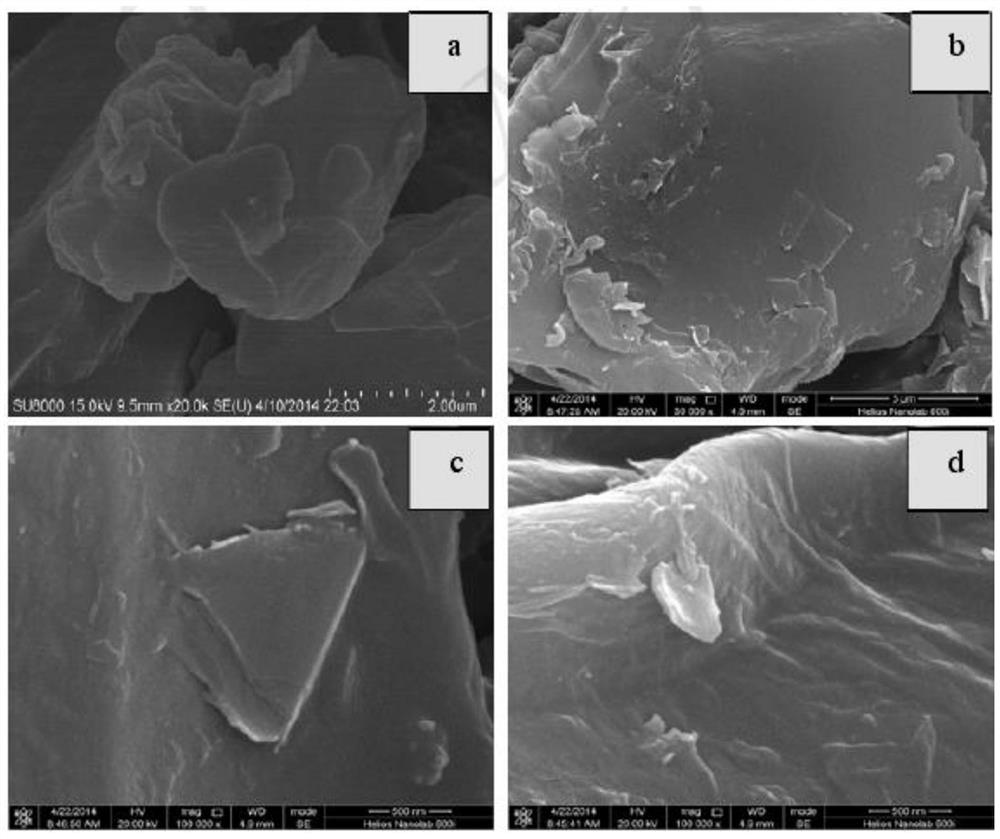

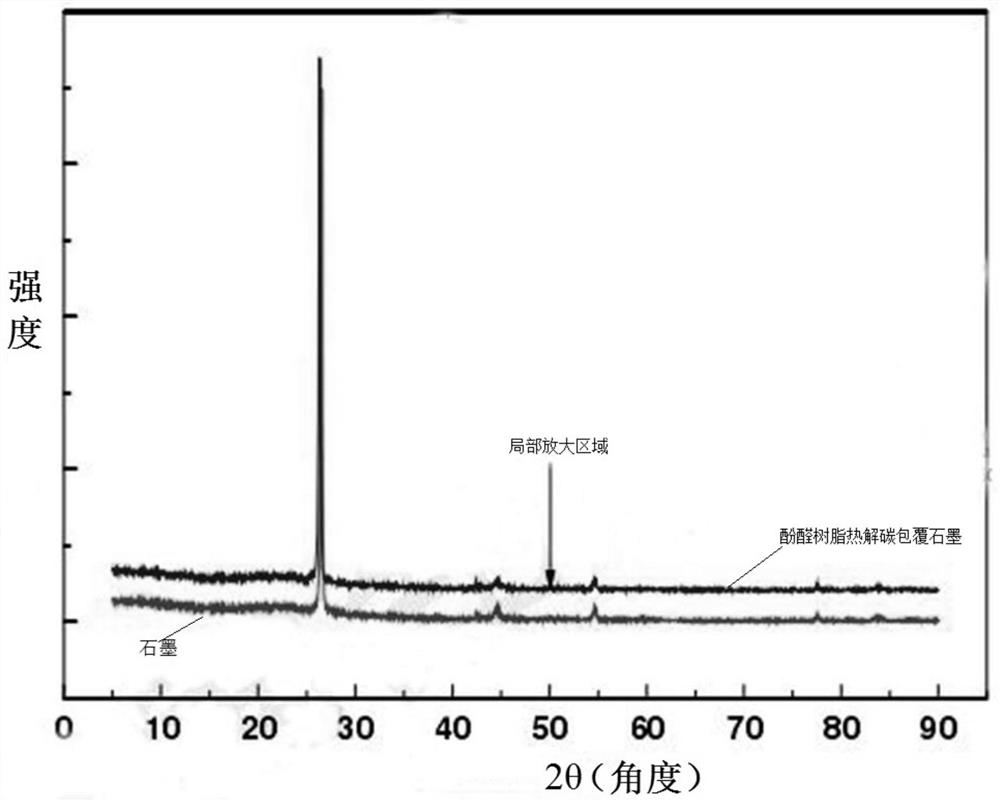

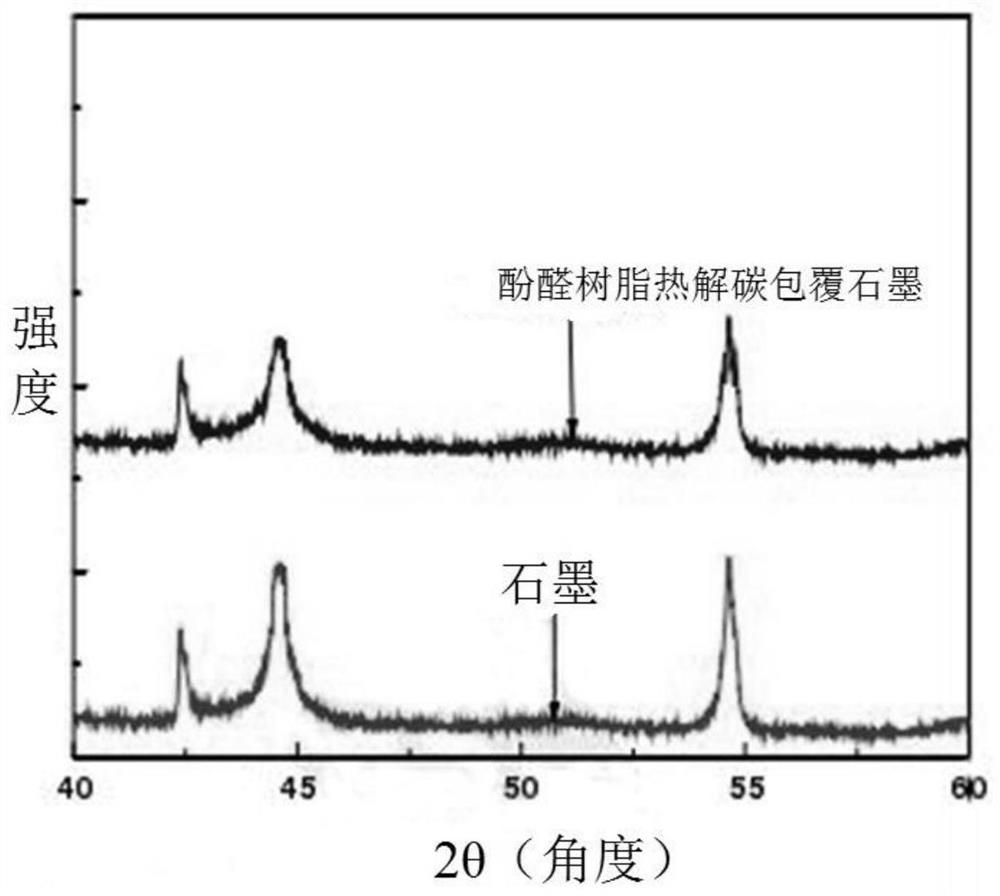

Image

Examples

Embodiment Construction

[0021] The following is a further description of the present invention, rather than limiting the application of the present invention. The phenolic resin used is boron-containing phenolic resin (oligomer, liquid, analytically pure) from Shaanxi Taihang Fire-retardant Polymer Co., Ltd., and the graphite is 1420 graphite (battery grade) from Huzhou Chuangya Power Battery Material Co., Ltd. From Tianjin Fuyu Fine Chemical Co., Ltd. (analytical pure).

[0022] Take by weighing 30 grams of phenolic resin, without curing, divide it into three parts, dissolve it in tetrahydrofuran respectively, and stir and ultrasonically alternately carry out until the phenolic resin is completely dissolved (that is, after the oligomeric phenolic resin is evenly dispersed in the solvent tetrahydrofuran to form a uniform solution), Add 1 gram, 5 grams, and 10 grams of graphite to three parts of tetrahydrofuran solutions of phenolic resins respectively, stir magnetically for ten hours to mix uniformly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com