Method for wrapping lithium cobalt oxide serving as anode material of lithium ion secondary battery through wet method

A cathode material, secondary battery technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of uneven coating of lithium cobalt oxide materials, affecting performance, uneven dispersion, etc., to improve poor cycle performance. , The effect of suppressing battery inflation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] 1) prepare the aqueous solution of zinc acetate, wherein, the weight ratio of zinc acetate and water is 1:500, and the pH value of aqueous solution is 7;

[0075] 2) Take 43ml of the aqueous solution in step 1), add 100g of positive electrode material lithium cobaltate to the aqueous solution, and stir at a stirring rate of 400rpm for 1h to form a slurry;

[0076] 3) After baking the slurry in step 2) in an oven at 100°C for 24 hours, pass through a 60-mesh sieve;

[0077] 4) The dried product in step 3) was calcined at 700° C. for 5 hours, cooled naturally to room temperature, ground properly, and passed through a 200-mesh sieve to obtain the coated material of the positive electrode material lithium cobaltate.

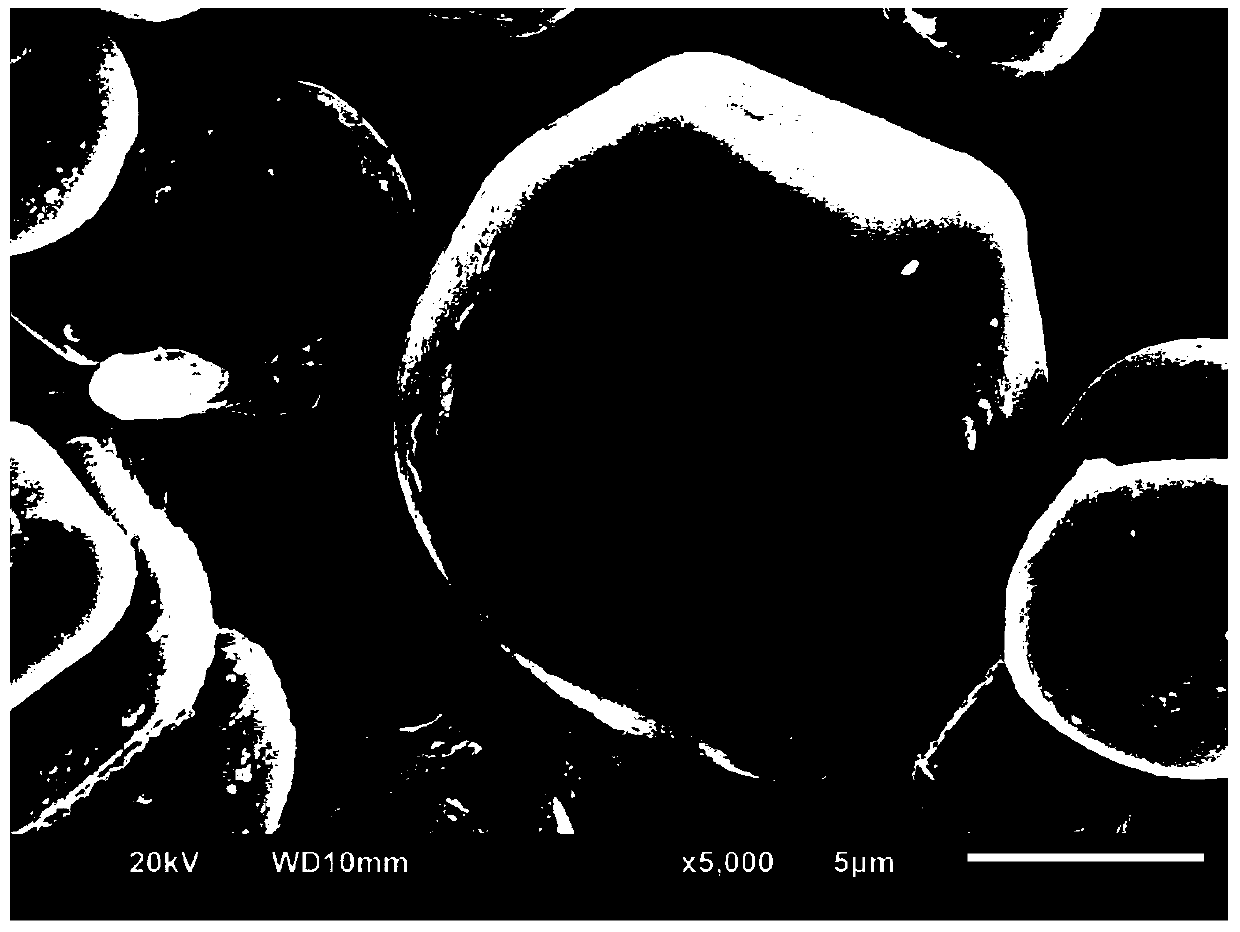

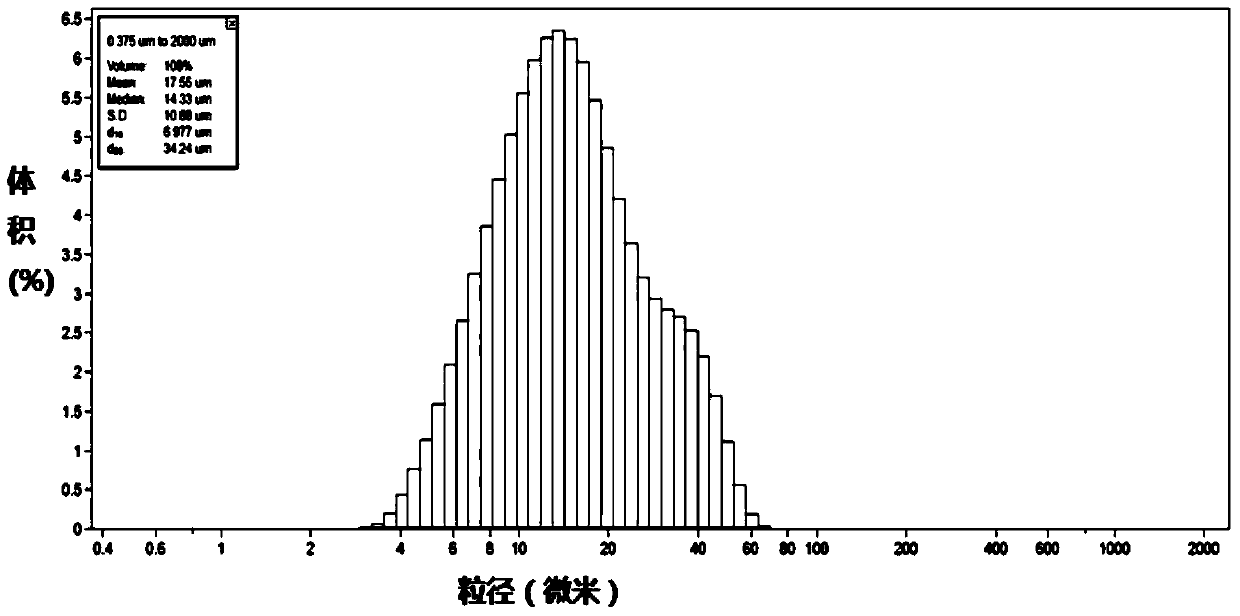

[0078] Measured by the Malvern particle size tester: the median diameter (D50) of the coated material is 14.3 microns;

[0079] After the final product is tested, the pH value is 10.3 and the specific surface area is 0.18m 2 / g;

Embodiment 2

[0081] 1) prepare the aqueous solution of magnesium acetate, wherein, the weight ratio of magnesium acetate and water is 1:500, and the pH value of aqueous solution is 7;

[0082] 2) Take 43ml of the aqueous solution in step 1), add 100g of positive electrode material lithium cobaltate to the aqueous solution, and stir at a stirring rate of 400rpm for 1h to form a slurry;

[0083] 3) After baking the slurry in step 2) in an oven at 100°C for 24 hours, pass through a 60-mesh sieve;

[0084] 4) The dried product in step 3) was calcined at 700° C. for 5 hours, cooled naturally to room temperature, ground properly, and passed through a 200-mesh sieve to obtain the coated material of the positive electrode material lithium cobaltate.

[0085] Measured by a Malvern particle size tester: the median diameter (D50) of the coated material is 14.1 microns.

[0086] After the final product is tested, the pH value is 10.3 and the specific surface area is 0.17m 2 / g.

Embodiment 3

[0088] 1) prepare the aqueous solution of manganese acetate, wherein, the weight ratio of manganese acetate and water is 1:500, and the pH value of aqueous solution is 7;

[0089] 2) Take 43ml of the aqueous solution in step 1), add 100g of positive electrode material lithium cobaltate to the aqueous solution, and stir at a stirring rate of 400rpm for 1h to form a slurry;

[0090] 3) Bake the slurry in step 2) in an oven at 100°C for 24 hours, and pass through a 60-mesh sieve;

[0091] 4) The dried product in step 3) was calcined at 700° C. for 5 hours, cooled naturally to room temperature, ground properly, and passed through a 200-mesh sieve to obtain the coated material of the positive electrode material lithium cobaltate.

[0092] Measured by a Malvern particle size tester: the median diameter (D50) of the coated material is 14.2 microns.

[0093] After the final product is tested, the pH value is 10.3 and the specific surface area is 0.18m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com