Lithium-ion battery cathode material and preparation method thereof

A technology of lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as safety hazards, cycle life, etc., to suppress battery flatulence, increase lithium ion diffusion rate and electronic conductivity, and improve lithium ion conductivity. Effect of ion diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The first step is to massage the molar ratio Li:Mn:Fe:P:surfactant=0.95:0.8:0.2:1:0.1 to prepare lithium hydroxide, manganese sulfate, ferrous sulfate, phosphoric acid, and cetyltrimethyl. Ammonium bromide, use deionized water to dissolve lithium hydroxide to prepare a 2.5mol / L aqueous solution, add manganese sulfate, ferrous sulfate, and phosphoric acid to a reactor with a reflux device, and then add deionized water to the reactor and stir Dissolve to form solution I, keep the total concentration of Mn and Fe in solution I at 1.8 mol / L, add ethylene glycol to the reactor according to the total volume of deionized water in solution I: the total volume of ethylene glycol is 1:1, Then add cetyltrimethylammonium bromide, slowly add lithium hydroxide solution into the reactor under continuous stirring, and then add 2.5mol / L NaOH solution to the mixture until the pH value of the mixed solution is adjusted to 8.0. Form mixture II;

[0028] In the second step, the reactor is pla...

Embodiment 2~23

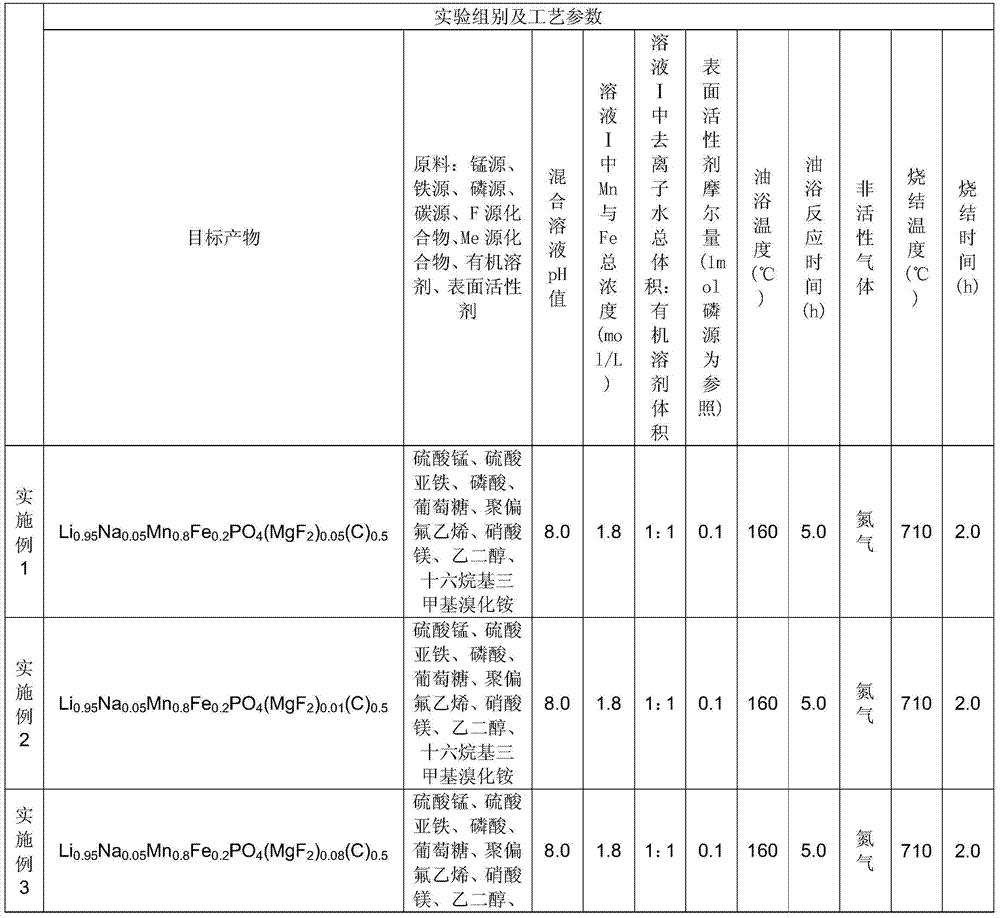

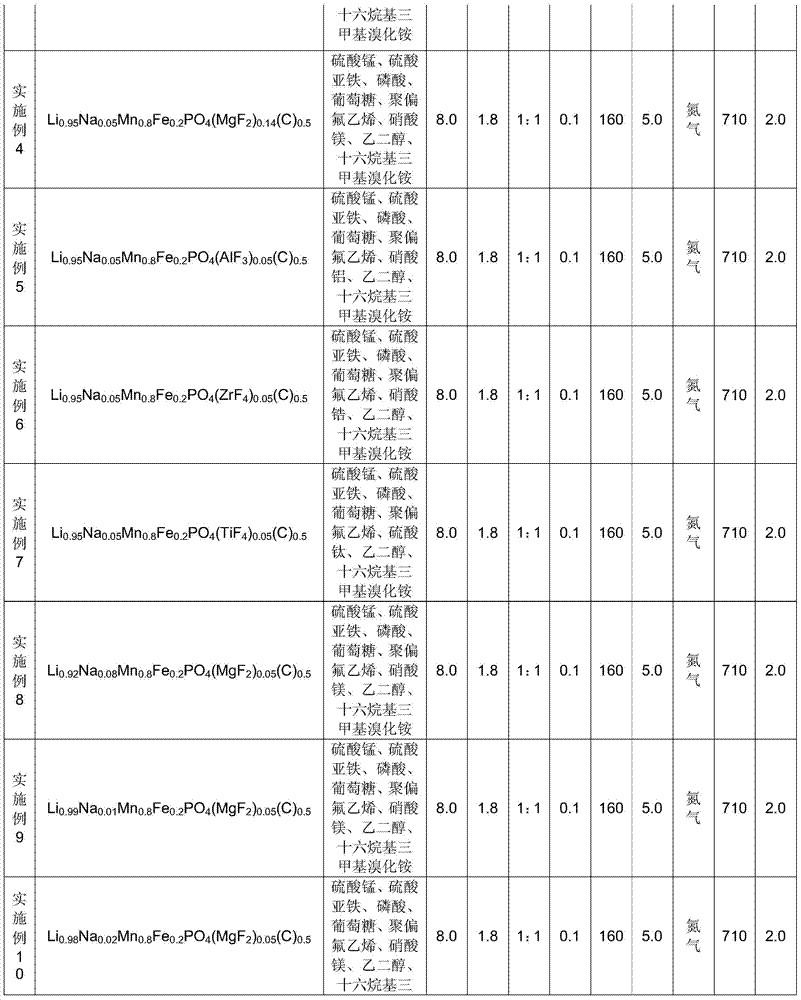

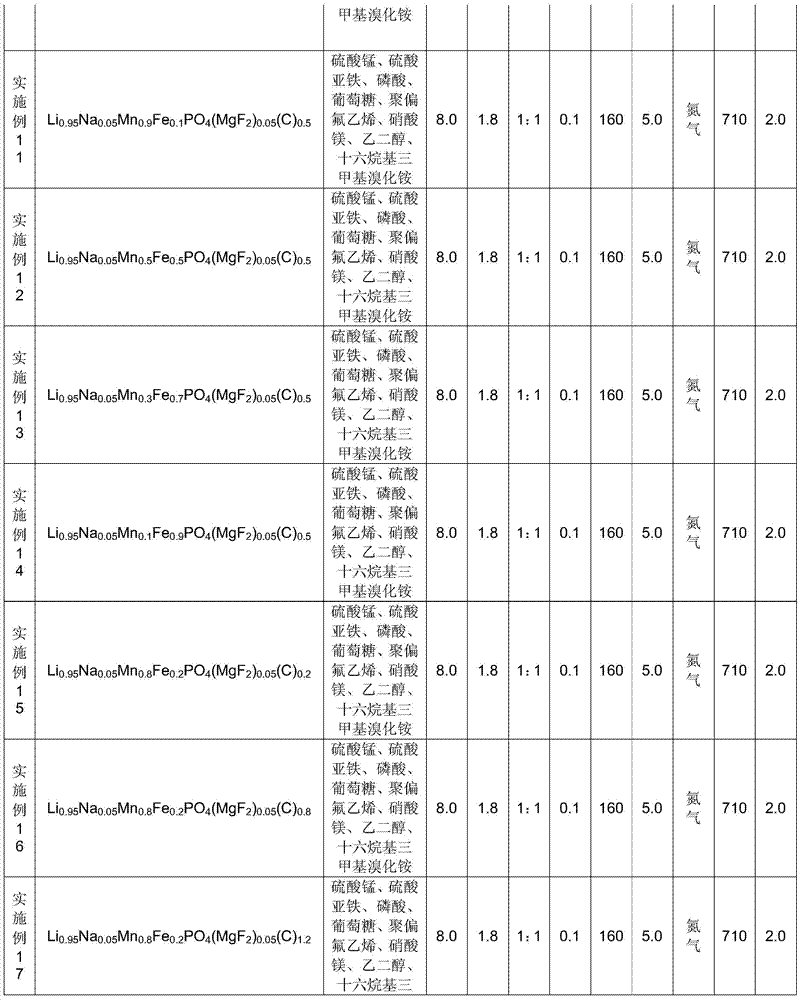

[0031] The chemical formula and raw material types of the obtained target product, the pH value of the liquid system, the calcination temperature and time and other process parameters are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com