Nano-scale cube cobalt stannate and graphene composite material and preparation method and application thereof

A composite material, cube technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve serious environmental problems, endanger ecology, unevenness and other problems, achieve electrochemical performance improvement, speed up The effect of speed and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

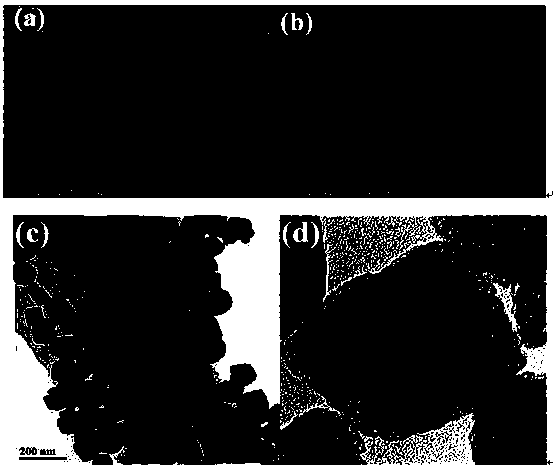

[0044] In the first step, 1mmol Na 2 SnO 3 Dissolve in 20ml deionized water to obtain solution A; 1mmol CoSO 4 Dissolve in 20ml deionized water to obtain solution B; add solution A dropwise to solution B, stir at room temperature for 0.5h; centrifuge wash the product with distilled water and absolute ethanol for 2-3 times, and then place it in an oven at 80°C After drying for 12 hours, the precursor CoSn(OH) of nanoscale cubes can be obtained 6 .

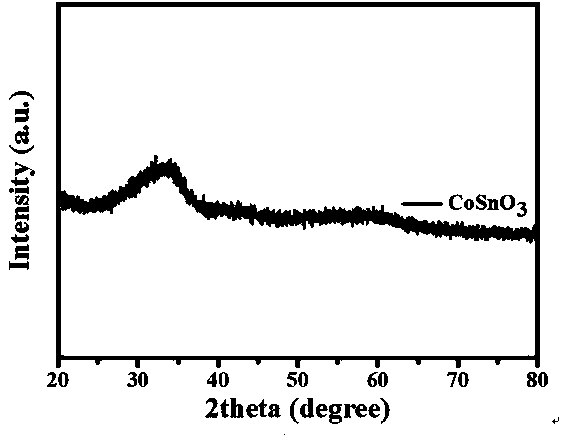

[0045] In the second step, the precursor CoSn(OH) 6 Place it in an atmosphere tube furnace and keep it warm for 4 hours at 300°C to obtain CoSnO with nanoscale cubic shape. 3 .

[0046] The third step is the preparation of electrode sheets for sodium-ion batteries for testing. Nanoscale cubic CoSnO 3 And natural carbon black, binder CMC (carboxymethyl cellulose) in a certain ratio (8:1:1) to prepare a sodium ion battery negative electrode test pole piece, the detailed method is:

[0047] (1) According to the ratio of 8:1:1, ...

Embodiment 2

[0055] The first step is the same as the first step in embodiment 1.

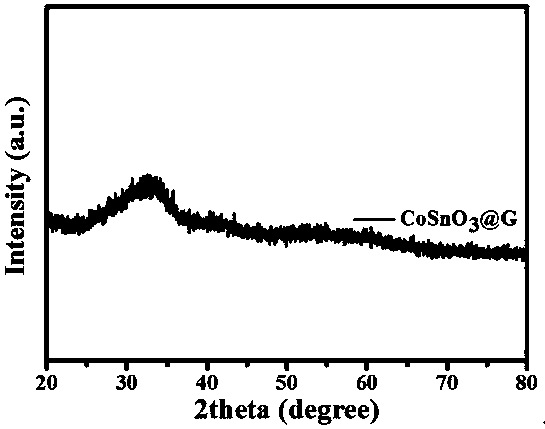

[0056] The second step is to grind graphite oxide to obtain a brownish-yellow powder; use an ultrasonic cell pulverizer to uniformly disperse 20mg of graphite oxide powder in 4ml of ethylene glycol, and prepare a 5mg / ml graphite oxide-ethylene glycol dispersion; weigh 50mg of precursor Bulk CoSn(OH) 6 At the same time, measure 30ml of butanol, add it to the prepared graphite oxide-ethylene glycol dispersion, and stir at room temperature for 0.5h; transfer the obtained precursor mixture to a polytetrafluoroethylene lining, and use a stainless steel reactor After sealing, heat to 200°C and keep it warm for 6 hours; after the reaction, cool to normal temperature at room temperature, take out the product, wash with deionized water and ethanol for 2-3 times, and freeze-dry; dry the obtained product at 300 Cubic CoSnO nanoscale was obtained after 4 hours of heat preservation at ℃ and natural cooling. 3 and grap...

Embodiment 3

[0066] The first step is the same as the first step in Example 1.

[0067] The second step is to grind graphite oxide to obtain a brownish-yellow powder; use an ultrasonic cell pulverizer to uniformly disperse 60mg of graphite oxide powder in 60ml of ethylene glycol, and prepare a 1mg / ml graphite oxide-ethylene glycol dispersion; weigh 200mg of precursor Bulk CoSn(OH) 6 At the same time, measure 50ml of butanol, add it to the prepared graphite oxide-ethylene glycol dispersion, and stir at room temperature for 0.5h; transfer the obtained precursor mixture to a polytetrafluoroethylene lining, and use a stainless steel reactor After sealing, heat to 120°C and keep it warm for 6 hours; after the reaction, cool to room temperature at room temperature, take out the product, wash with deionized water and ethanol for 2-3 times, and freeze-dry; dry the obtained product at 300 Cubic CoSnO nanoscale was obtained after 4 hours of heat preservation at ℃ and natural cooling. 3 and graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com