Sulfur-doped carbon material and preparation method thereof

A carbon material, sulfur doping technology, used in electrical components, battery electrodes, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] At the same time, the present invention also discloses the preparation method of the above-mentioned sulfur-doped carbon material, which specifically includes: mixing antimony acetate, thioacetamide and ethylene glycol, stirring vigorously to obtain a mixed solution; then placing the mixed solution in a grinding chamber Add ethylenediaminetetraacetic acid into the bowl for grinding to obtain a precursor; then sinter the precursor to obtain the sulfur-doped carbon material.

[0019] According to the present invention, firstly, a mixed solution is prepared, and the mixed solution includes antimony acetate, thioacetamide and ethylene glycol. Specifically, antimony acetate and thioacetamide can be put into a stirring bottle first, and then ethylene glycol is added for vigorous stirring.

[0020] In the mixed solution, the relative content of antimony acetate, thioacetamide and ethylene glycol can vary within a wide range. Preferably, in the above-mentioned mixed solution, t...

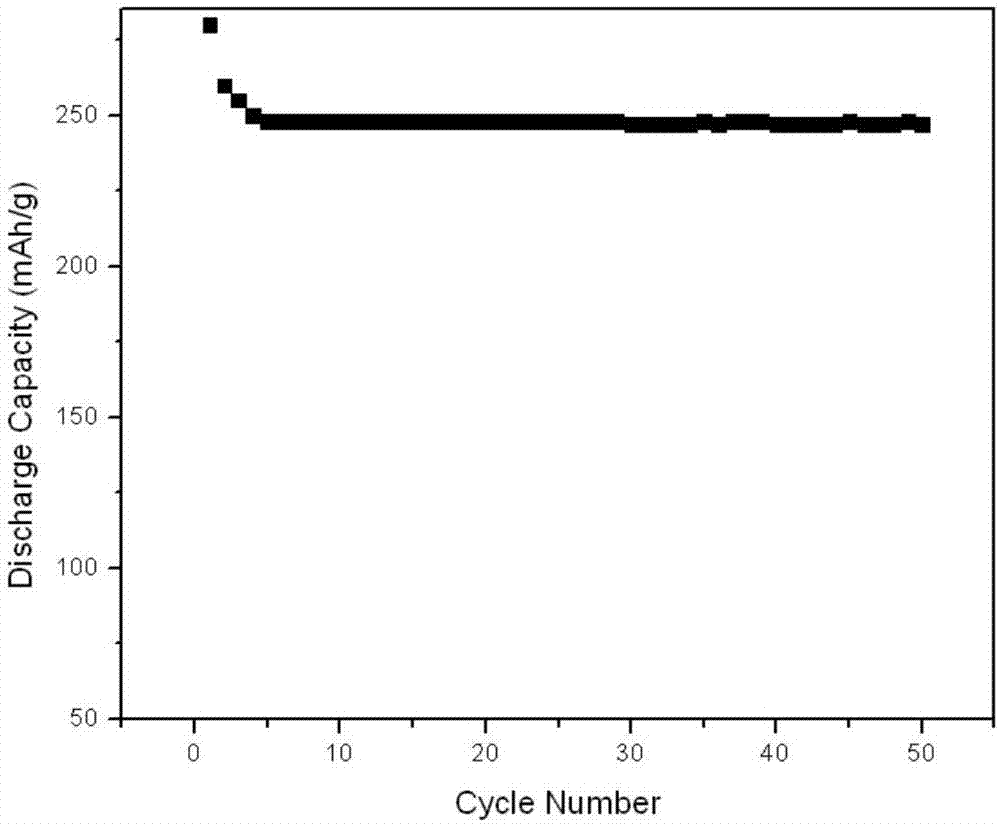

Embodiment 1

[0032] This example is used to illustrate the sulfur-doped carbon material disclosed in the present invention and its preparation method.

[0033] Dissolve 4.5g of antimony acetate and 4.5g of thioacetamide in 6ml of ethylene glycol, and vigorously stir at room temperature for 12h to prepare a uniform mixture. Transfer the resulting mixture to a mortar, add 1 g of ethylenediaminetetraacetic acid, and grind for 2 hours. Antimony acetate and thioacetamide used were purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., and ethylene glycol was purchased from Sinopharm Chemical Reagents. Co., Ltd., all are analytically pure.

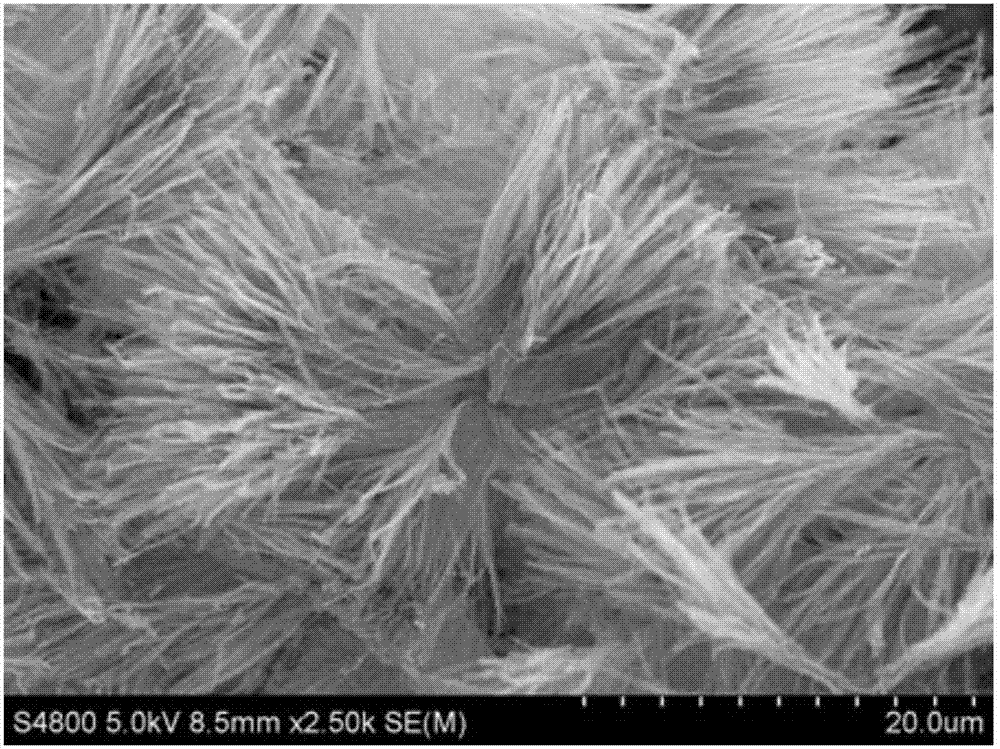

[0034] Put the above-mentioned precursor obtained by grinding into a tube furnace, pass through argon gas with a purity of 99.99% at a flow rate of 40 mL / min, heat to 800 °C at a heating rate of 2 °C / min, keep the temperature for 4 hours, and then naturally cool to room temperature , the obtained black product is the sulfur-doped carbon material,...

Embodiment 2

[0040] This example is used to illustrate the sulfur-doped carbon material disclosed in the present invention and its preparation method.

[0041] Dissolve 3g of antimony acetate and 3g of thioacetamide in 6ml of ethylene glycol, and vigorously stir at room temperature for 12 hours to prepare a uniform mixed solution, transfer the obtained mixed solution to a mortar, add 2g of ethylenediaminetetraacetic acid, Grinding for 4h.

[0042] Put the above-mentioned precursor obtained by grinding in a tube furnace, feed argon gas with a purity of 99.99% at a flow rate of 40 mL / min, heat to 900 °C at a heating rate of 2 °C / min, keep the temperature for 4 hours, and then naturally cool to room temperature , the obtained black product is the sulfur-doped carbon material.

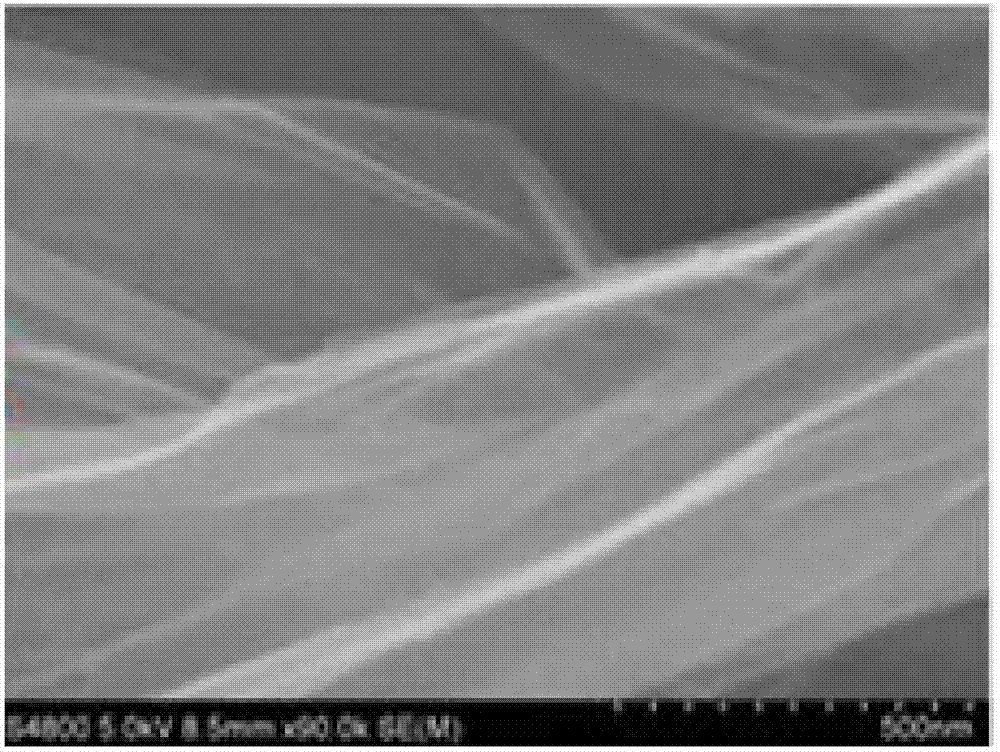

[0043] According to element content analysis, the sulfur element content in Example 2 is 5wt%.

[0044] image 3 SEM image of the sulfur-doped carbon material prepared in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com