A kind of high-performance lithium-ion secondary battery negative electrode material Si/C composite material and preparation method thereof

A technology for composite materials and secondary batteries, which is applied in the direction of secondary batteries, battery electrodes, active material electrodes, etc., can solve the problems of high cost, troublesome preparation steps, and electrochemical performance to be improved, and achieve low cost and excellent electrochemical performance. Performance, the effect of realizing the effective use of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

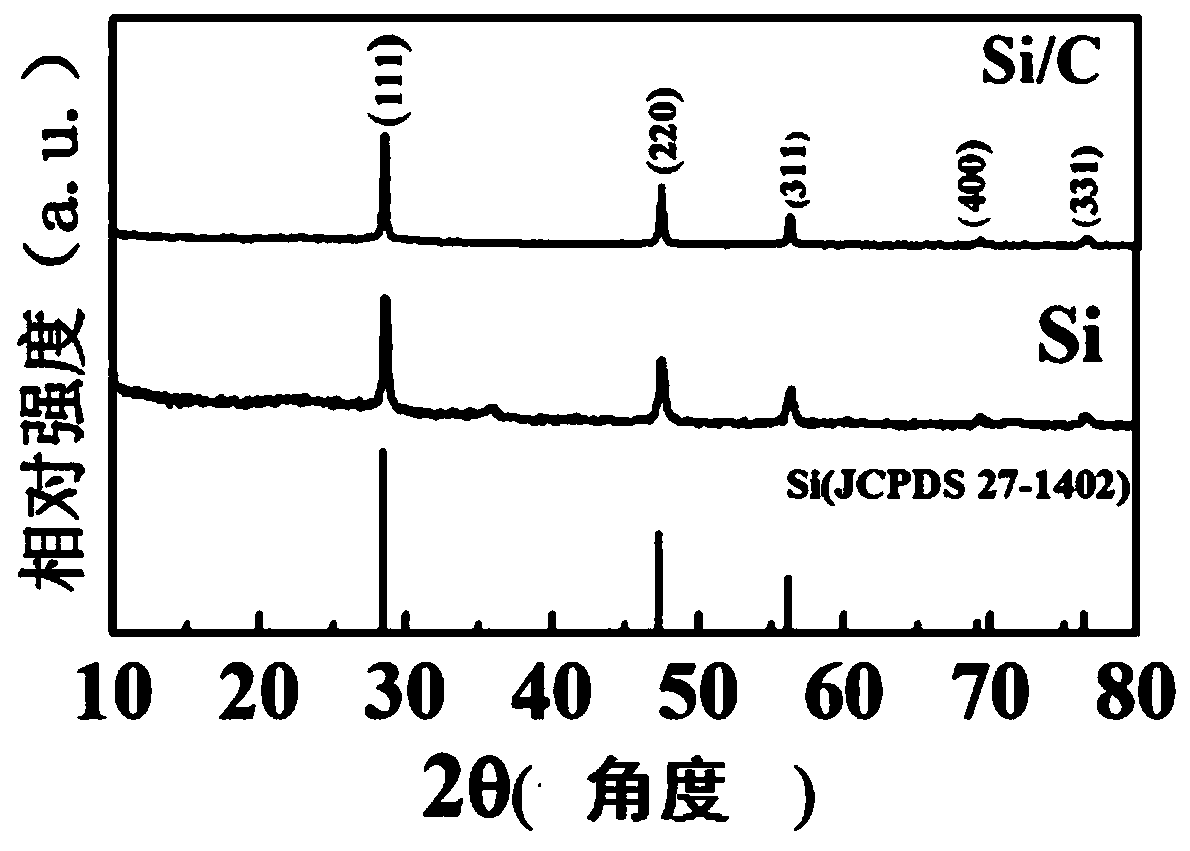

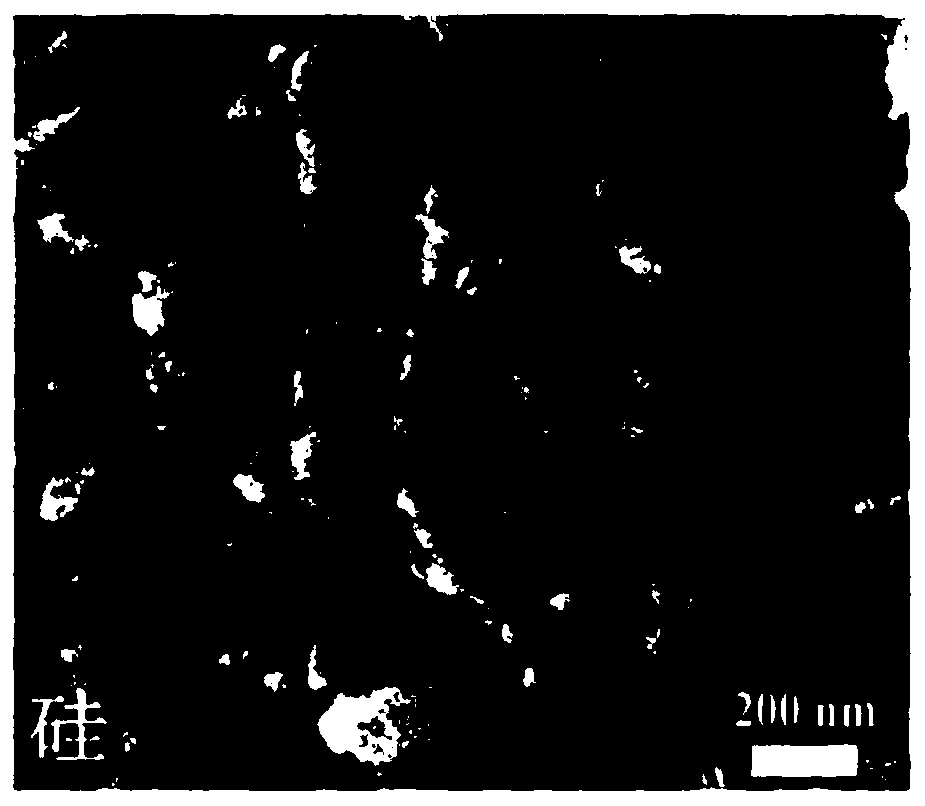

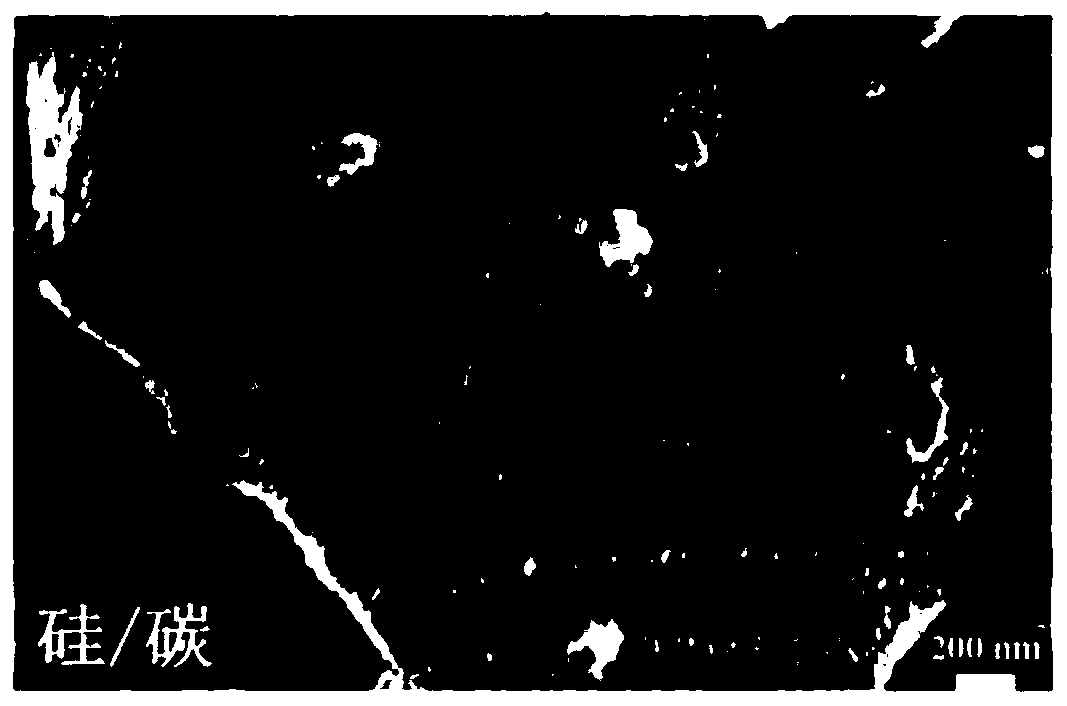

[0050] A high-performance lithium-ion secondary battery negative electrode material Si / C composite material, the composite material includes a composite of carbon and silicon, the mass content of carbon in the composite is 30%, and the mass content of silicon is 70%; the The microscopic morphology of the composite material is: the surface of the Si nanoparticles is covered with a carbon layer to form a carbon-silicon nanocomposite ball, and is loaded on the surface of the sheet-like carbon; the size of the Si nanoparticles is 20nm, and the carbon layer The thickness is 5nm, and the diameter of the pellet is about 25nm.

[0051] The preparation method of the above-mentioned high-performance lithium-ion secondary battery negative electrode material Si / C composite material comprises the following steps:

[0052] (1) Soak 5 g of bagasse collected in 50 mL of 1mol / L HCl aqueous solution at room temperature for 2 hours to remove inorganic salt impurities, alternately wash with water...

Embodiment 2

[0058] A kind of preparation method of Si / C composite material of anode material of high-performance lithium ion secondary battery, comprises steps as follows:

[0059] (1) Soak 10 g of bagasse collected in 50 mL of 1mol / L HCl aqueous solution at room temperature for 4 hours to remove inorganic salt impurities, alternately wash with water and absolute ethanol three times, and dry in an oven at 90 ° C for 10 h; then , calcined at 650°C in air for 4h, and the heating rate was set at 2°C / min, to obtain white fluffy SiO 2 powder;

[0060] (2) 1g of SiO prepared in step (1) 2 Grind and mix with 1.5g magnesium powder in a mortar and transfer to a porcelain boat, and then quickly transfer to Ar / H 2 (volume ratio 95:5) atmosphere tube furnace, calcined at 600°C for 7h, the heating rate was set at 2°C / min, to obtain the mixture; put the above mixture into 50mL 1mol / L HCl solution (HCl:H 2 (0: molar ratio of dehydrated ethanol=0.66:4.72:8.88) soaked at room temperature for 8 hours, d...

Embodiment 3

[0063] A kind of preparation method of Si / C composite material of anode material of high-performance lithium ion secondary battery, comprises steps as follows:

[0064] (1) Soak 15g of bagasse collected in 50mL of 1mol / L HCl aqueous solution at room temperature for 6 hours to remove inorganic salt impurities, alternately wash with water and absolute ethanol three times respectively, and dry in an oven at 100°C for 8h; then , calcined at 700°C in air for 3h, and the heating rate was set at 5°C / min to obtain white fluffy SiO 2 powder;

[0065] (2) 1g of SiO prepared in step (1) 2 Grind and mix well with 2g magnesium powder in a mortar, transfer to a porcelain boat, and then quickly transfer to Ar / H 2 (volume ratio is 95:5) atmosphere tube furnace, calcined at 700°C for 6.5h, the heating rate was set at 5°C / min, to obtain the mixture; put the above mixture into 50mL 1mol / L HCl solution (HCl:H 2 (0: molar ratio of dehydrated ethanol=0.66:4.72:8.88) soaked at room temperature fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com