Carrier material for positive electrode of lithium-sulfur battery and preparation method thereof

A carrier material, lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, positive electrodes, etc., can solve the problems of low utilization rate of active materials, poor conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

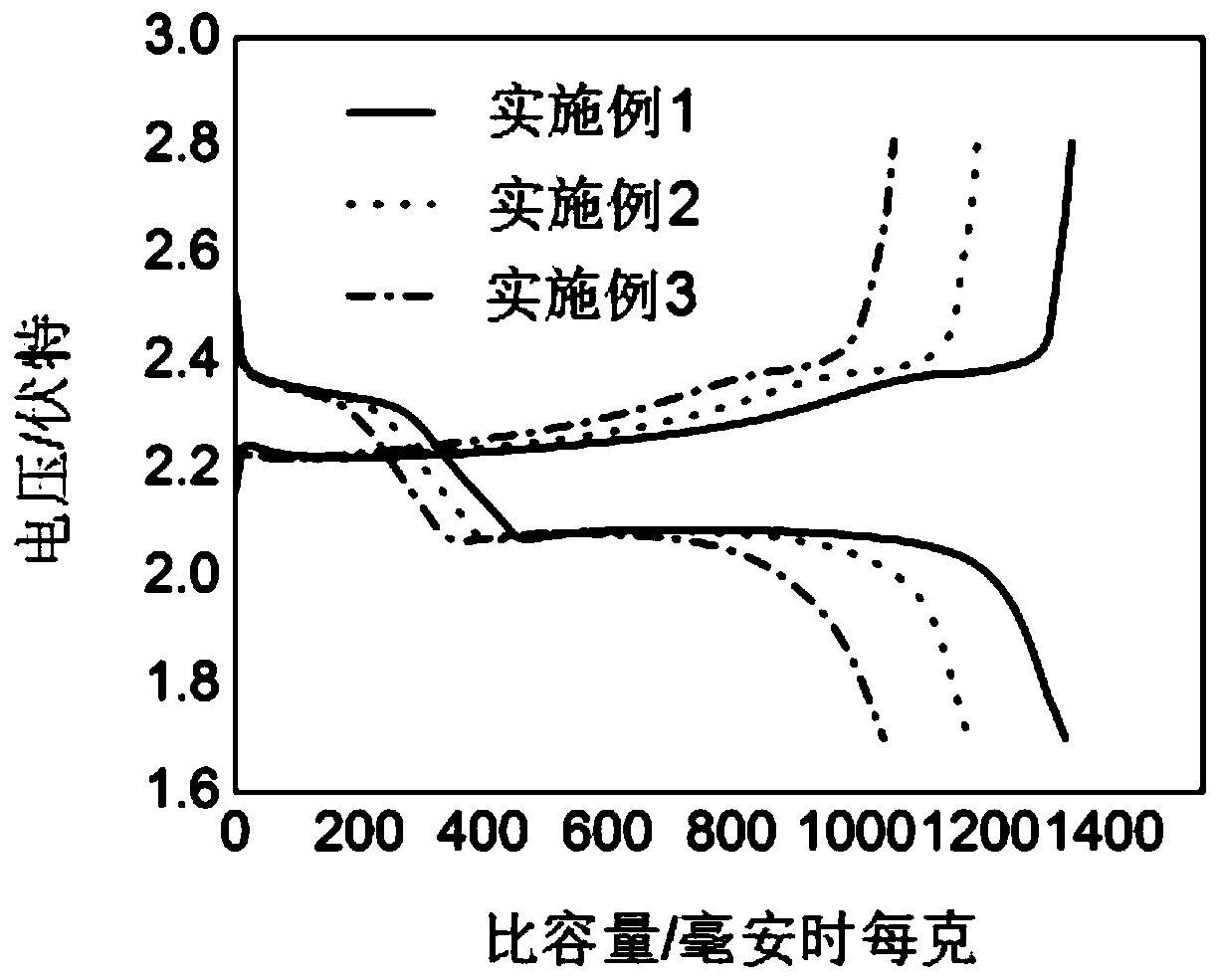

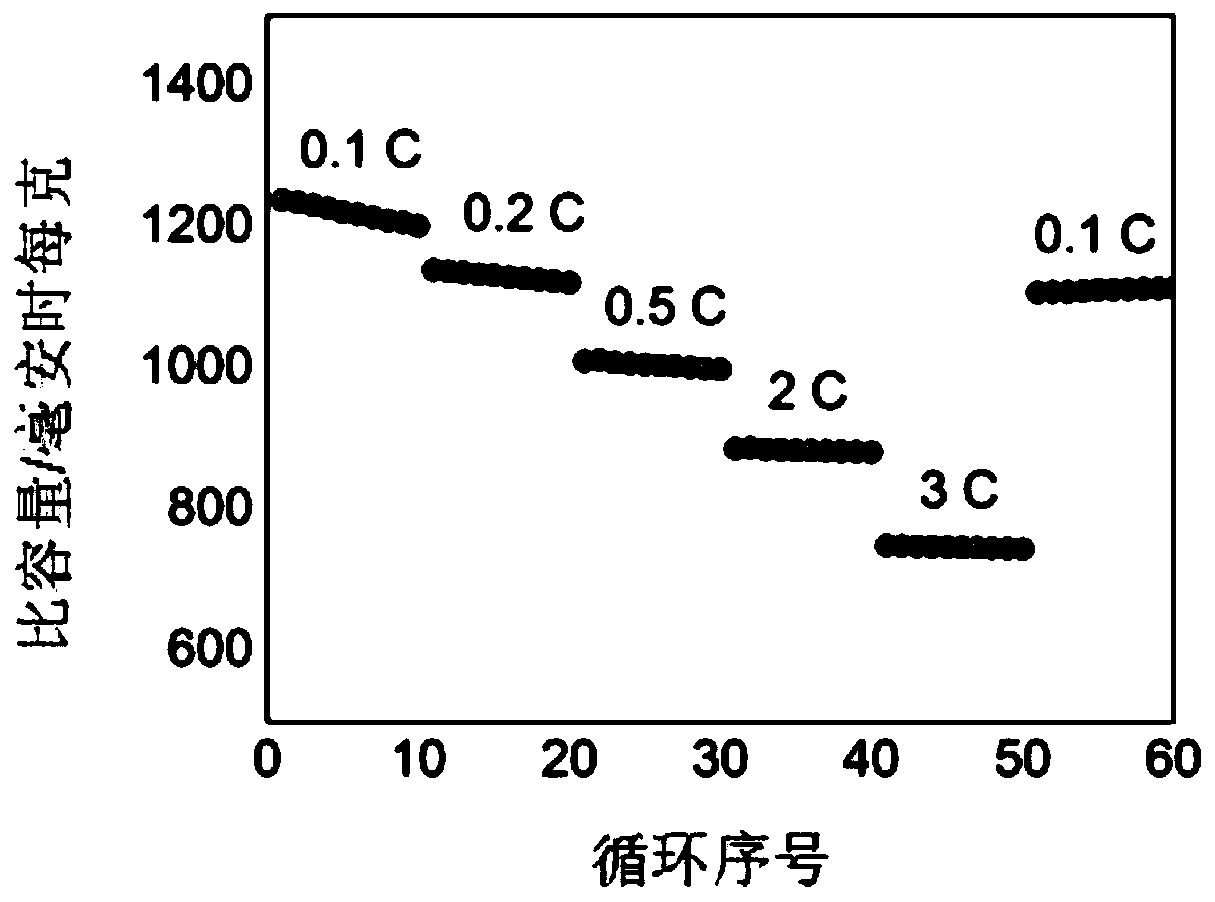

Embodiment 1

[0024] The carrier material used for the positive electrode of the lithium-sulfur battery is Nb-Nb with a one-dimensional mesoporous nanoribbon array 4 N 5 composite material.

[0025] The preparation method of the carrier material for the positive electrode of lithium-sulfur battery comprises the following steps:

[0026] (1) Preparation of Nb-KNb 3 o 8 Composite material: The niobium metal foil is firstly polished with SiC sandpaper, then ultrasonically cleaned with acetone, ethanol and deionized water for 5 minutes respectively, dried under a flowing nitrogen atmosphere and then soaked in 40mL of KOH solution with a concentration of 0.01mol / L Put it in the reaction kettle and heat it up to 175°C for 15 hours. After the reaction is completed, cool it down to room temperature naturally to get Nb-KNb 3 o 8 composite materials;

[0027] (2) Preparation of Nb-Nb 2 o 5 Composite material: with step (1) gained Nb-KNb 3 o 8 The composite material was placed in HNO with a ...

Embodiment 2

[0033] The preparation method of the carrier material for the positive electrode of lithium-sulfur battery comprises the following steps:

[0034] (1) Preparation of Nb-KNb 3 o 8 Composite material: The niobium metal foil is first polished with SiC sandpaper, then ultrasonically cleaned with acetone, ethanol and deionized water for 2 minutes respectively, dried under a flowing nitrogen atmosphere and then soaked in 20mL of KOH solution with a concentration of 0.001mol / L Put it in the reactor and heat it up to 150°C for 10 hours. After the reaction is completed, cool it down to room temperature naturally to get Nb-KNb 3 o 8 composite materials;

[0035] (2) Preparation of Nb-Nb 2 o 5 Composite material: with step (1) gained Nb-KNb 3 o 8 The composite material was placed in HNO with a concentration of 1mol / L 3 Immerse in the solution for 12 hours for protonation; after the completion of protonation, rinse with deionized water until neutral, dry at room temperature, place...

Embodiment 3

[0040] The preparation method of the carrier material for the positive electrode of lithium-sulfur battery comprises the following steps:

[0041] (1) Preparation of Nb-KNb 3 o 8 Composite material: The niobium metal foil is first polished with SiC sandpaper, then ultrasonically cleaned with acetone, ethanol and deionized water for 10 minutes respectively, dried under a flowing nitrogen atmosphere and then soaked in 60 mL of KOH solution with a concentration of 0.03 mol / L Put it in the reactor and heat it up to 200°C for 20 hours. After the reaction is completed, cool it down to room temperature naturally to get Nb-KNb 3 o 8 composite materials;

[0042] (2) Preparation of Nb-Nb 2 o 5 Composite material: with step (1) gained Nb-KNb 3 o 8 The composite material was placed in HNO with a concentration of 3mol / L 3 Immerse in the solution for 36 hours for protonation; after the completion of protonation, rinse with deionized water until neutral, dry at room temperature, pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First cycle discharge capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| First cycle discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com