A lithium ion battery cathode material, preparation method and application thereof

A lithium-ion battery and cathode material technology, applied in the field of lithium-ion battery cathode materials and their preparation, can solve the problems of low self-discharge, complex process, poor electrode performance, etc., and achieve easy large-scale production, simple process, and excellent discharge ratio. The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment is a preparation method of a lithium-ion battery positive electrode material, the preparation method comprising the following steps:

[0047] One side of the expanded graphite sheet is coated with conductive glue, and the other side is used as a cathode and placed in an organic electrolyte solution for electrolysis. Subsequently, the graphene electrode material obtained by electrolysis is cleaned with acetone, and dried at 50°C to obtain a graphene electrode. , the organic electrolyte solution is DMSO and LiClO 4 solution; the electrolysis voltage is 1v, and the electrolysis time is 5h;

[0048] LiCoO 2 Perform ball milling and ultrasonically disperse in water to obtain a suspension, in which LiCoO 2 The concentration is 20g / L, LiCoO after ball milling 2 The particle size is 0.1-3μm, and the ball milling time is 10h;

[0049] Put the graphene electrode and the metal electrode into the suspension, and apply an electric field between the two electrodes...

Embodiment 2

[0053] This embodiment is a preparation method of a lithium-ion battery positive electrode material, the preparation method comprising the following steps:

[0054] One side of the expanded graphite sheet is coated with conductive glue, and the other side is used as a cathode and placed in an organic electrolyte solution for electrolysis. Subsequently, the electrolytic graphene electrode material is cleaned with acetic acid solution, and dried at 45°C to obtain a graphene electrode. Among them, the organic electrolyte solution is dimethyl sulfone and Et 3 NHC solution; electrolysis voltage is 2v, electrolysis time is 4h;

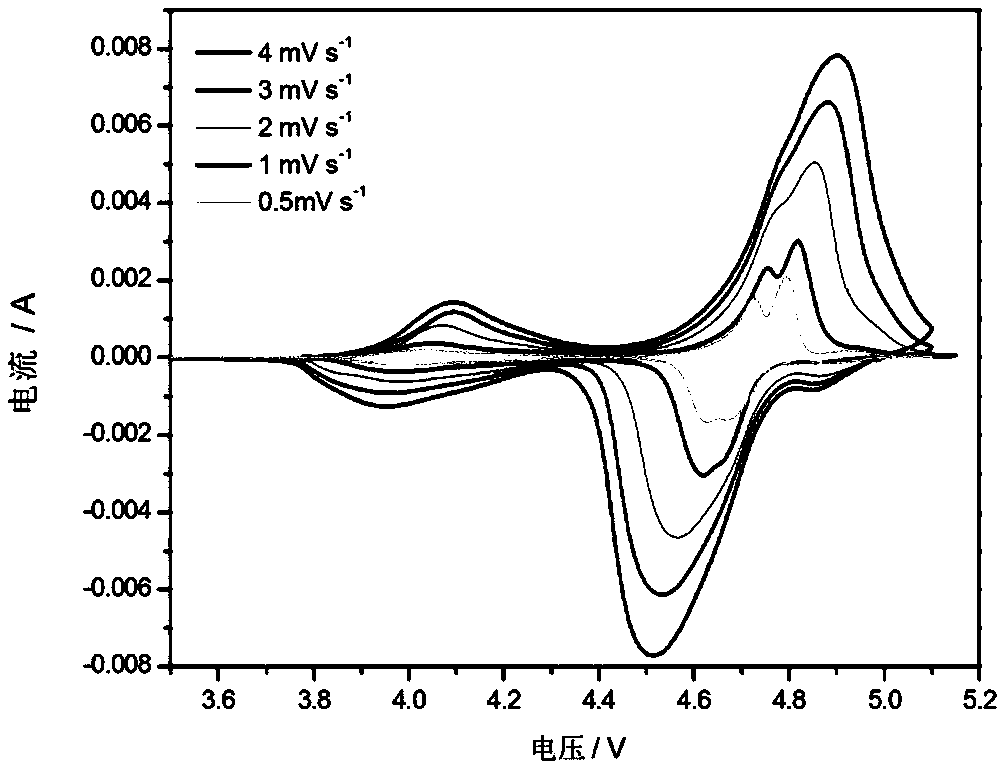

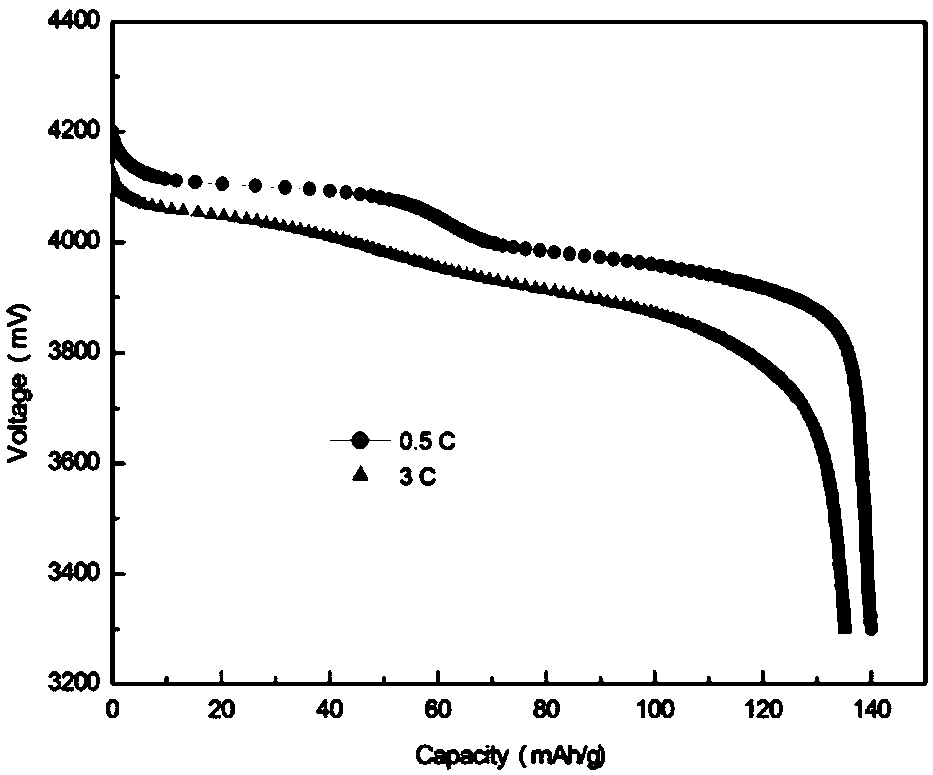

[0055] Will LiNi 0.5 mn 1.5 o 4 Perform ball milling and ultrasonically disperse in N-methylpyrrolidone to obtain a suspension, in which LiNi 0.5 mn 1.5 o 4 The concentration is 10g / L, LiNi after ball milling 0.5 mn 1.5 o 4 The particle size is 0.1-3μm, and the ball milling time is 10h;

[0056] Put the graphene electrode and the metal electrode in...

Embodiment 3

[0060] This embodiment is a preparation method of a lithium-ion battery positive electrode material, the preparation method comprising the following steps:

[0061] One side of the expanded graphite sheet is coated with conductive glue, and the other side is used as a cathode and placed in an organic electrolyte solution for electrolysis. Subsequently, the graphene electrode material obtained by electrolysis is cleaned with ethanol, and dried at 55 ° C to obtain a graphene electrode. , the organic electrolyte solution is a solution of dimethyl sulfide and 1-methyl-3-ethylimidazolium diimine; the electrolysis voltage is 3v, and the electrolysis time is 3h;

[0062] LiMn 2 o 4 Perform ball milling and ultrasonic dispersion in ethylene glycol, acetone and N-methylpyrrolidone to obtain a suspension, in which LiMn 2 o 4 The concentration is 50g / L, LiMn after ball milling 2 o 4 The particle size is 1.1-3μm, and the ball milling time is 2h;

[0063] Put the graphene electrode a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com