Nanofiber framework-based sodium-ion battery positive electrode material and preparation method and application thereof

A technology for sodium ion batteries and positive electrode materials, which is applied in the manufacture of electrodes, battery electrodes, secondary batteries, etc. It can solve the problems of poor sodium ion diffusion kinetics, poor structural stability of carrier materials, and poor electrochemical cycle performance. Achieve reliable cycle performance, good discharge specific capacity, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] See also shown in the figure, a kind of sodium ion battery cathode material and preparation method thereof based on nanofibrous skeleton of the present invention, comprises the following steps:

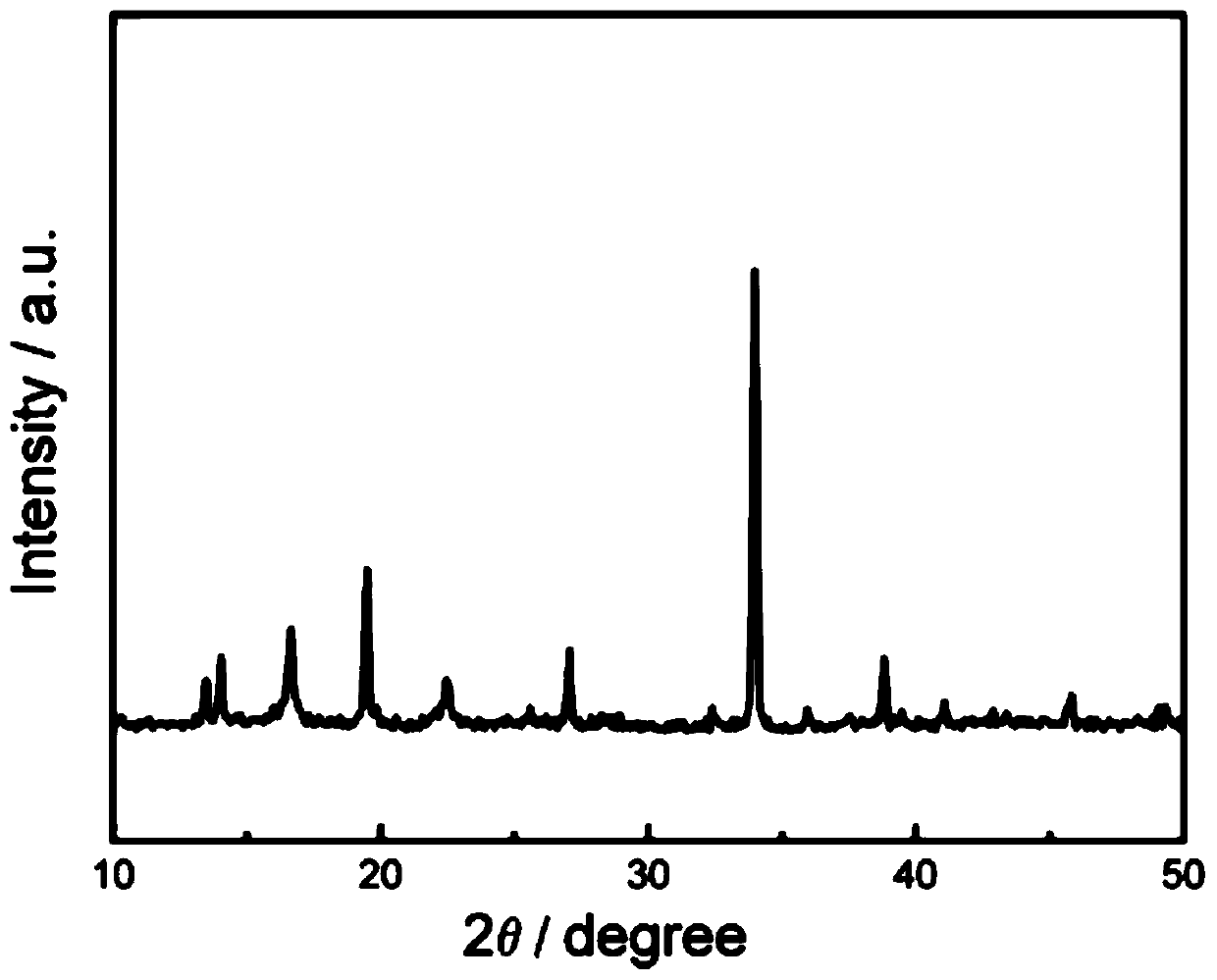

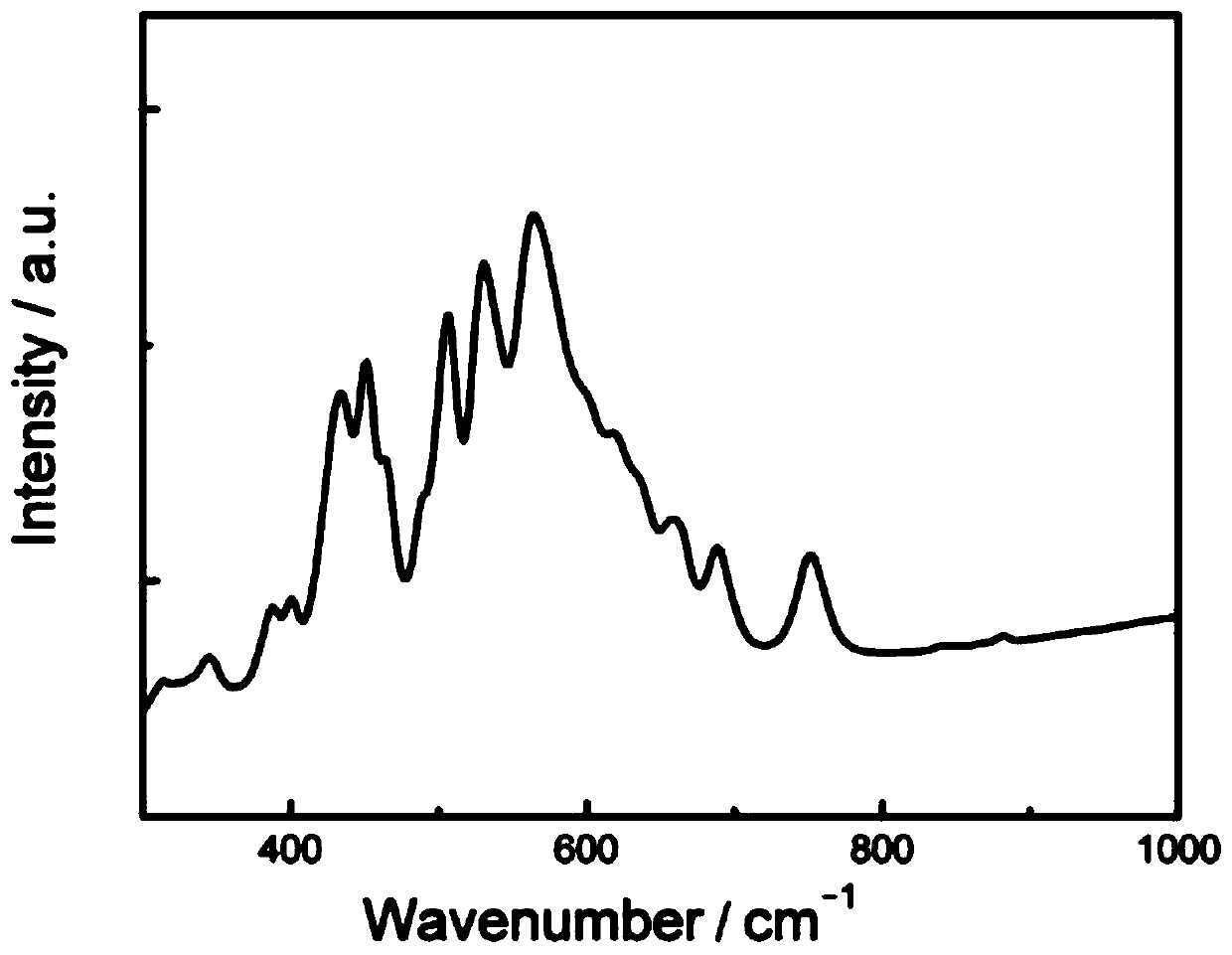

[0036] S1, the Na 2 CO 3 and Mn 2 o 3 As a raw material, use a certain molar ratio of Na / Mn, use alcohol as a ball milling medium, ball mill and mix evenly on a planetary ball mill, and dry and grind at a certain temperature to obtain a powder precursor; then calcined in a muffle furnace to decompose carbonate , then calcined at high temperature and cooled to room temperature to obtain Na 0.44 MnO 2 single crystal;

[0037] Sodium and manganese salts are Na 2 CO 3 , Mn2 o 3 , and grind according to n(Na) / n(Mn)=0.4~0.5 molar ratio.

[0038] The amount of alcohol in the ball milling medium is 5% to 10% of the total amount of sodium salt and manganese salt. During ball milling, the dry grinding temperature is 40 to 50°C, the grinding time is 4 to 6 hours, and the muffle f...

Embodiment 1

[0045] Weigh Na with n(Na) / n(Mn)=0.4 2 CO 3 and Mn 2 o 3 Put it into a ball mill, add 5wt% alcohol as a ball milling medium and a dispersant, dry and grind at 40° C. for 4 hours, and obtain a powdery precursor.

[0046] Calcined at 200°C for 7h in a muffle furnace to decompose carbonate, and then calcined at a high temperature of 700°C for 8h. get Na 0.44 MnO 2 single crystal material.

[0047] Configure Na with a mass fraction of 20% 0.44 MnO 2 solution, and then add 0.3g PVP to the solution to obtain an electrospinning solution, then transfer the above solution to a syringe, and prepare Na by electrospinning device 0.44 MnO 2 fiber.

[0048] The setting conditions of the electrospinning machine are electrode distance 20cm, voltage 30KV, syringe needle diameter 0.03cm, spinning dope injection speed 1ml / h. get Na 0.44 MnO 2 fiber material.

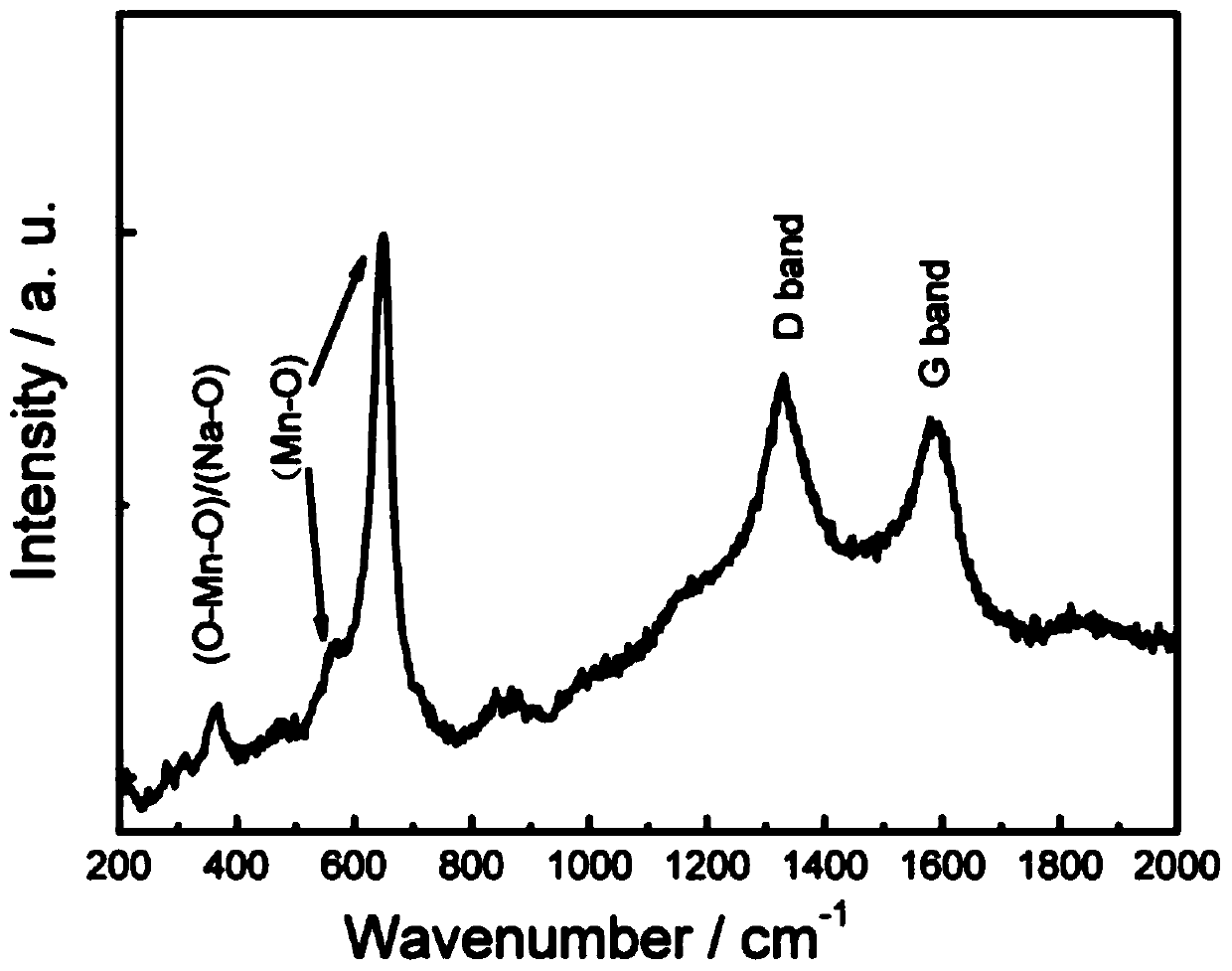

[0049] Na 0.44 MnO 2 Mix the nanofibrous material and CNTs evenly, and use a ball mill to mill for 4 hours to obtain Na ...

Embodiment 2

[0053] Weigh Na with n(Na) / n(Mn)=0.46 2 CO 3 and Mn 2 o 3 Put it into a ball mill, add 8wt% alcohol as a ball milling medium and a dispersant, and dry and grind at 45°C for 5 hours to obtain a powdery precursor;

[0054] Calcined in a muffle furnace at 300°C for 8h to decompose carbonate, and then calcined at a high temperature of 800°C for 9h to obtain Na 0.44 MnO 2 single crystal material;

[0055] Configure Na with a mass fraction of 23% 0.44 MnO 2 solution, and then add 0.4g PVP to the solution to obtain an electrospinning solution, then transfer the above solution to a syringe, and prepare Na by electrospinning device 0.44 MnO 2 fiber;

[0056] The setting conditions of the electrospinning machine are electrode distance 23cm, voltage 35KV, syringe needle diameter 0.04cm, spinning dope injection speed 1.20ml / h. get Na 0.44 MnO 2 fiber material;

[0057] Na 0.44 MnO 2 Mix the rice fiber material and CNTs evenly, and use a ball mill to mill for 4 hours to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com