Three-dimensional current collector/Zn/Zn-E composite negative electrode, preparation thereof and application of composite negative electrode in aqueous zinc ion battery

A current collector, three-dimensional technology, applied in the direction of electrode carrier/current collector, battery electrode, secondary battery, etc., can solve the problems of dendrite zinc body utilization, zinc body side reactions, hydrogen evolution corrosion, etc., to improve the electrochemical reaction Rate, Utilization Improvement, Effect of Utilization Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

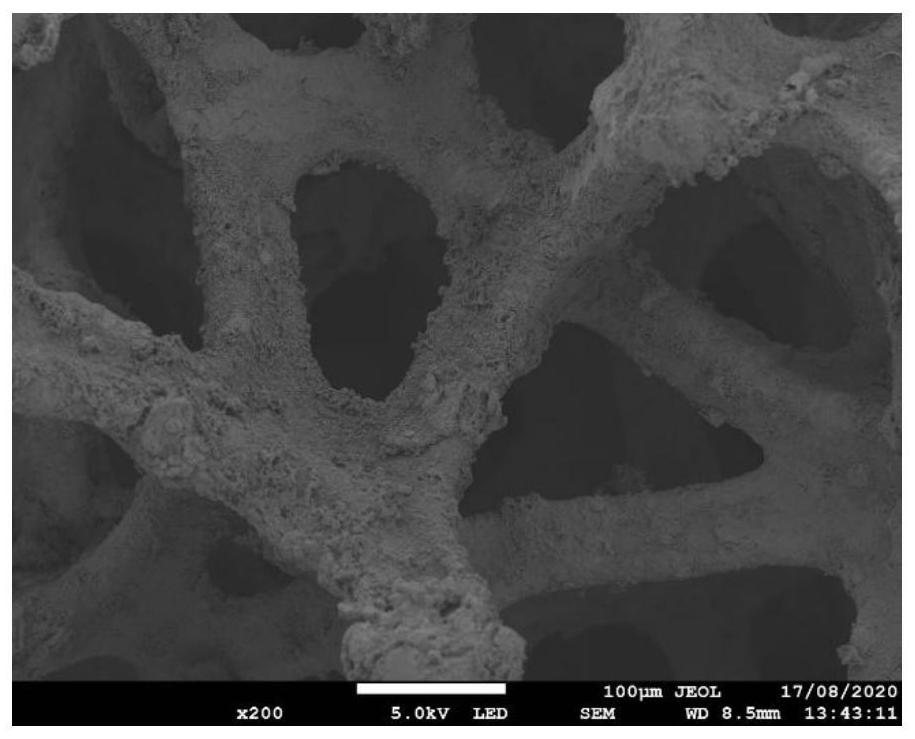

[0096] (1) Three-dimensional current collector copper mesh (pore size 0.1-1 mm, porosity 90%, thickness 0.5 mm) was pretreated, the copper mesh was placed in a 0.1M HCl solution for acidification for 3 minutes to obtain uniform nucleation sites, and then It was ultrasonically cleaned with deionized water for 5 minutes to remove the HCl solution and dried at room temperature; the acidified three-dimensional current collector was cut out to a size of 4.5 × 3.5 cm as the cathode

[0097] (2) Equipped with zinc bulk layer deposition electrolyte I, equipped with 0.5M zinc sulfate, 0.2M sodium sulfate, 0.5M sodium chloride aqueous solution;

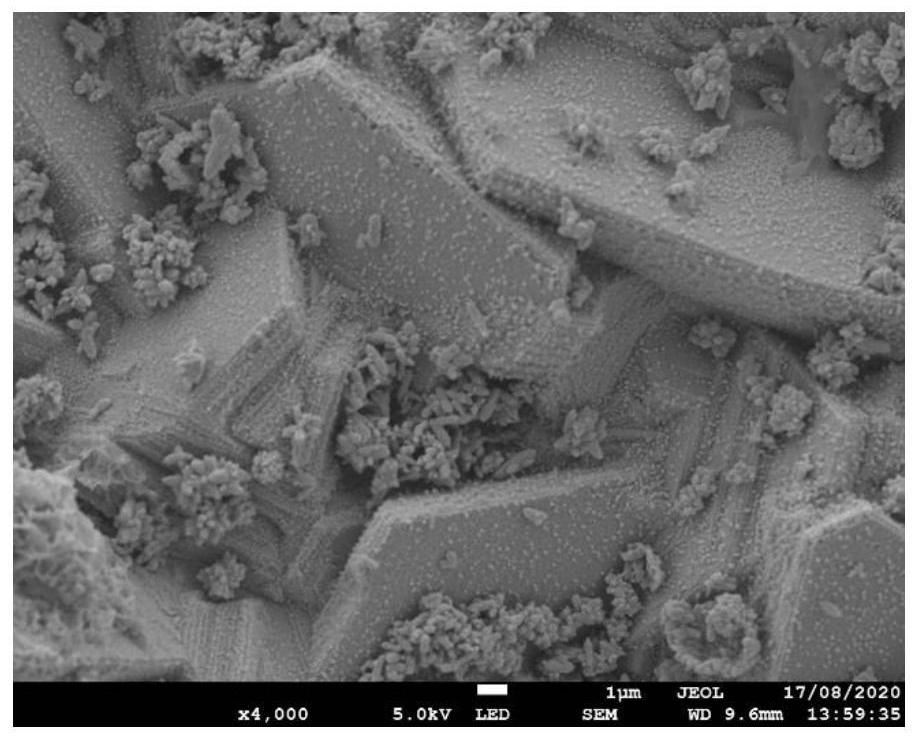

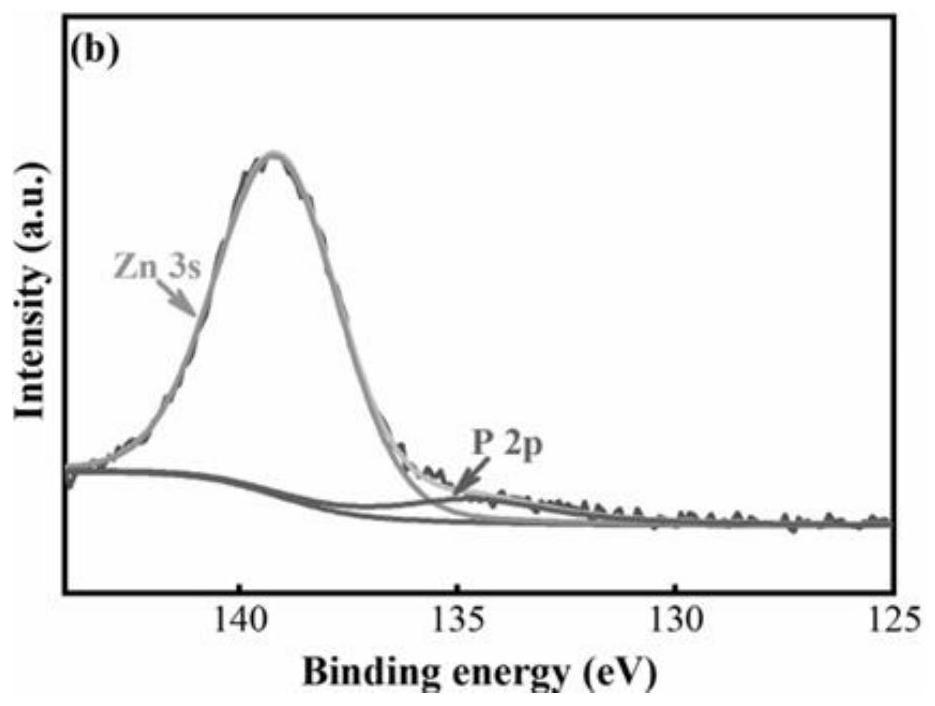

[0098] Equipped with 0.4M zinc sulfate, 0.15M sodium phosphate, 0.08M boric acid, 0.28M sodium sulfate, 0.34M sodium chloride, 0.006M ethylenediaminetetraacetic acid aqueous solution as plating electrodeposition electrolyte II;

[0099] (3) The zinc foil is used as the anode, the three-dimensional current collector treated in the step (1) is th...

Embodiment 2

[0107] (1) Three-dimensional current collector copper mesh (pore size 0.1-1 mm, porosity 90%, thickness 0.5 mm) was pretreated, the copper mesh was placed in a 0.1M HCl solution for acidification for 3 minutes to obtain uniform nucleation sites, and then It was ultrasonically cleaned with deionized water for 5 minutes to remove the HCl solution and dried at room temperature; the acidified three-dimensional current collector was cut out to a size of 4.5 × 3.5 cm as the cathode

[0108] (2) Equipped with zinc body layer deposition electrolyte I, equipped with 0.3M zinc sulfate, 0.3M sodium sulfate, 0.8M sodium chloride aqueous solution;

[0109] Equipped with 0.1M zinc sulfate, 0.1M sodium phosphate, 0.01M boric acid, 0.1M sodium sulfate, 0.1M sodium chloride, 0.001M ethylenediaminetetraacetic acid aqueous solution as plating electrodeposition electrolyte II;

[0110] (3) The zinc foil is used as the anode, the three-dimensional current collector treated in the step (1) is the c...

Embodiment 3

[0114] (1) Three-dimensional current collector copper mesh (pore size 0.1-1 mm, porosity 90%, thickness 0.5 mm) was pretreated, the copper mesh was placed in a 0.1M HCl solution for acidification for 3 minutes to obtain uniform nucleation sites, and then It was ultrasonically cleaned with deionized water for 5 minutes to remove the HCl solution and dried at room temperature; the acidified three-dimensional current collector was cut out to a size of 4.5 × 3.5 cm as the cathode

[0115] (2) Equipped with zinc bulk layer deposition electrolyte I, equipped with 0.5M zinc sulfate, 0.2M sodium sulfate, 0.5M sodium chloride aqueous solution;

[0116] Equipped with 1M zinc sulfate, 0.5M sodium phosphate, 0.1M boric acid, 0.5M sodium sulfate, 1M sodium chloride, 0.01M ethylenediaminetetraacetic acid aqueous solution as plating electrodeposition electrolyte II;

[0117] (3) The zinc foil is used as the anode, the three-dimensional current collector treated in the step (1) is the cathode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com