Method for modifying lithium nickel manganese oxide positive electrode material for lithium ion battery

A lithium-ion battery, lithium nickel manganate technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as affecting the modification effect, and achieve the effect of improving the modification effect and excellent cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

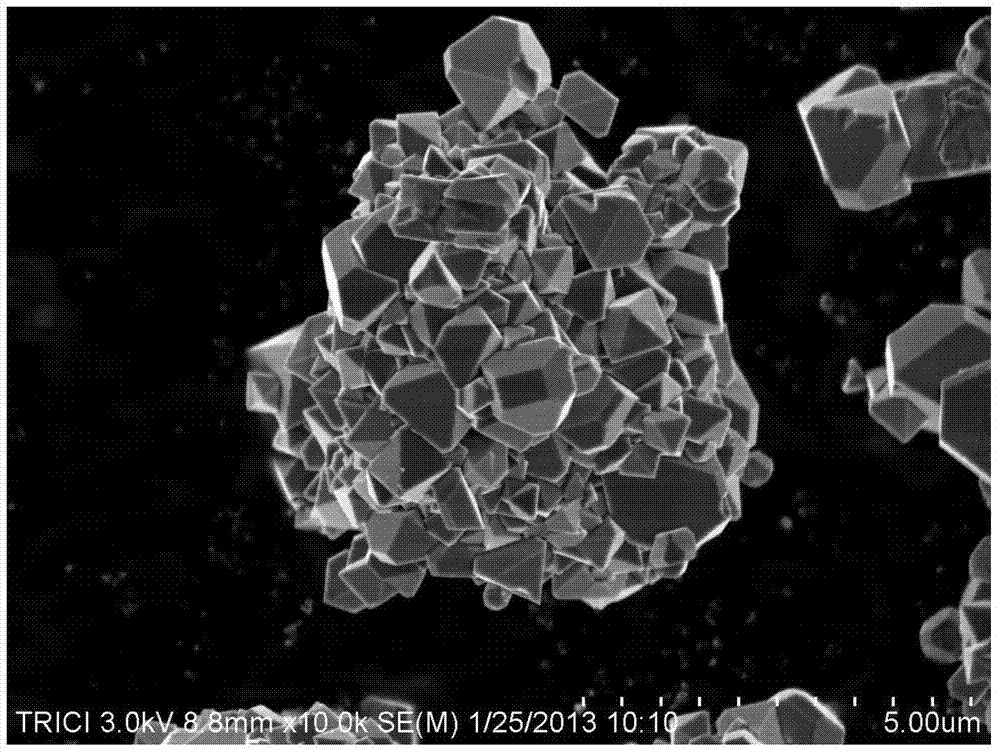

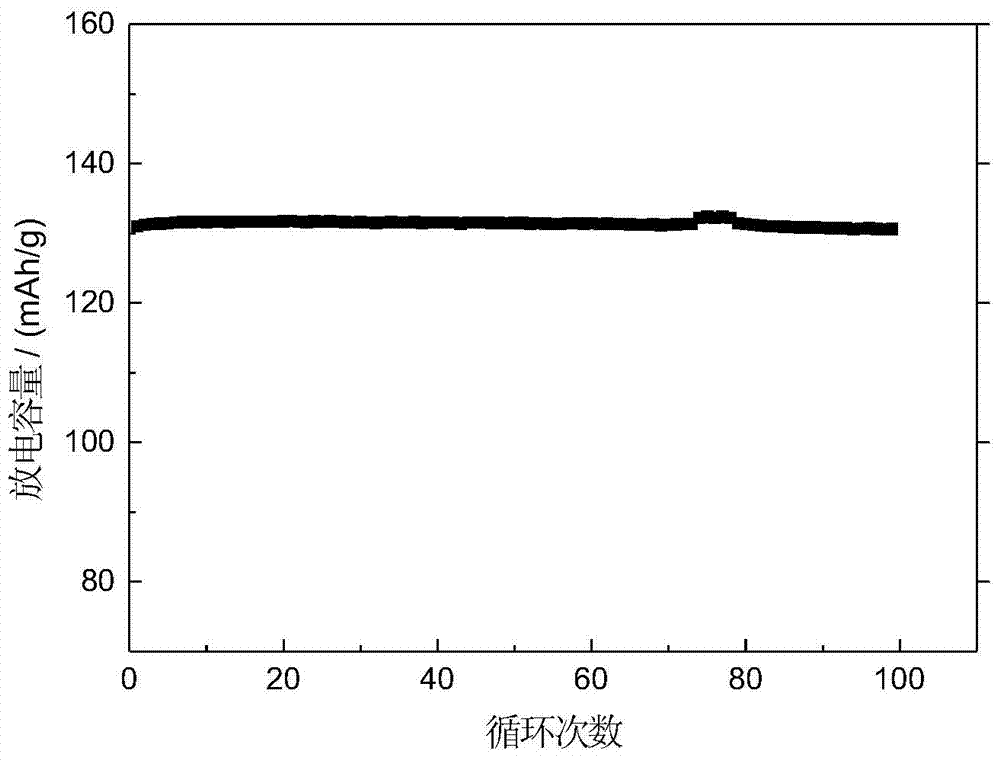

[0023] Example 1: Lithium nickel manganese oxide LiNi with the coating amount of alumina 0.5 mn 1.5 o 4 1% of the mass of the material calculates the molar amount of aluminum element, and then converts the molar amount and mass of sodium metaaluminate, and weighs lithium nickel manganate and sodium metaaluminate, and prepares sodium metaaluminate to a concentration of 0.1mol / L solution. Add lithium nickel manganese oxide to water, add 1g lithium nickel manganese oxide per 20mL of water, ultrasonically activate for 15 minutes to obtain a suspension, and then add hexadecyl trimethyl with a mass of 0.5% lithium nickel manganese oxide to the suspension Ammonium bromide, ultrasonically disperse for 15 minutes; then add sodium metaaluminate solution, the addition amount is 5% of the prepared sodium metaaluminate solution, and continue ultrasonication for 15 minutes; while stirring, pass carbon dioxide gas into the mixed solution until the pH of the solution is 8.0, then continue...

Embodiment 2

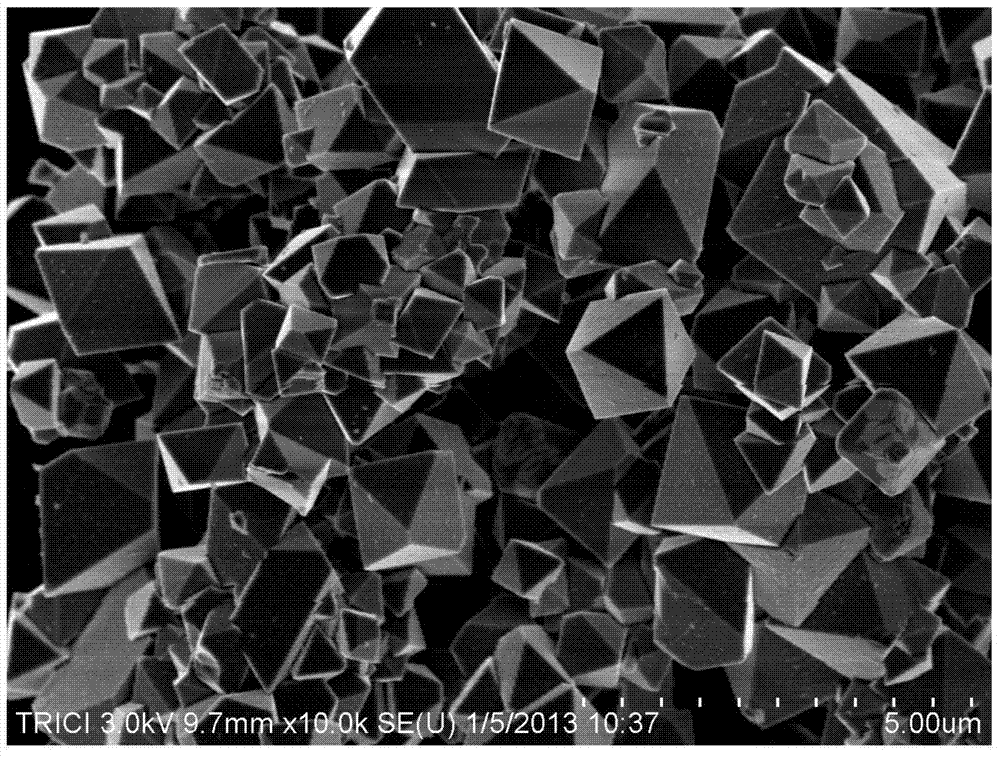

[0024] Embodiment 2: LiNi lithium nickel manganate with the coating amount of aluminum oxide 0.5 mn 1.5 o 43% of the material mass Calculate the molar amount of aluminum element, and then convert the molar amount and mass of sodium metaaluminate, and weigh lithium nickel manganate and sodium metaaluminate, and prepare sodium metaaluminate to a concentration of 0.3mol / L solution. Add lithium nickel manganese oxide to water, add 1g lithium nickel manganese oxide per 30mL of water, and ultrasonically activate for 15 minutes to obtain a suspension, then add dodecyl trimethyl with a mass of 1% of the mass of lithium nickel manganese oxide to the suspension Ammonium bromide, ultrasonically disperse for 15 minutes; then add sodium metaaluminate solution, the addition amount is 10% of the prepared sodium metaaluminate solution, and continue ultrasonication for 15 minutes; while stirring, pass carbon dioxide gas into the mixed solution until the pH of the solution is 9.0, then cont...

Embodiment 3

[0025] Embodiment 3: Lithium nickel manganese oxide LiNi with the coating amount of aluminum oxide 0.5 mn 1.5 o 4 5% of the mass of the material calculates the molar amount of aluminum element, and then converts the molar amount and mass of sodium metaaluminate, and weighs lithium nickel manganate and sodium metaaluminate, and prepares sodium metaaluminate to a concentration of 0.5mol / L solution. Add lithium nickel manganese oxide to water, add 1g lithium nickel manganese oxide per 40mL of water, ultrasonically activate for 15min to obtain a suspension, and then add hexadecyl trimethyl with a mass of 2% lithium nickel manganese oxide to the suspension Ammonium bromide, ultrasonically disperse for 15 minutes; then add sodium metaaluminate solution, the addition amount is 10% of the prepared sodium metaaluminate solution, and continue ultrasonication for 15 minutes; while stirring, pass carbon dioxide gas into the mixed solution until the pH of the solution is 10.0, then con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com