Preparation method of electrode material graphene nanometer sheet and electrode sheet prepared therefrom

A technology of graphene nanosheets and electrode materials, which is applied in the manufacture of electrolytic capacitors, hybrid capacitor electrodes, and hybrid/electric double layer capacitors. It can solve the problems of not using graphene supercapacitor electrode materials and achieve excellent electrochemical performance. The effect of easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Weigh 5.5g of natural flake graphite and add it to a mixture of 90ml of concentrated sulfuric acid (98% concentration) and 47.5ml of concentrated nitric acid (65% concentration) at 0-4°C, then add 5 grams of potassium chlorate every 5 minutes , a total of 55 grams, after 96 hours of continuous reaction, rinse repeatedly with 0.1mol / L dilute hydrochloric acid and then deionized water until no chlorine ions and sulfate ions are detected and the pH value reaches neutral. After drying in a drying oven at 60°C, grind and sieve to obtain graphite oxide powder.

[0018] Put 0.1g of graphite oxide powder into a 100ml crucible and put it into a muffle furnace preheated to 1000°C in an air atmosphere for rapid heat treatment for 30 seconds to obtain expanded graphite.

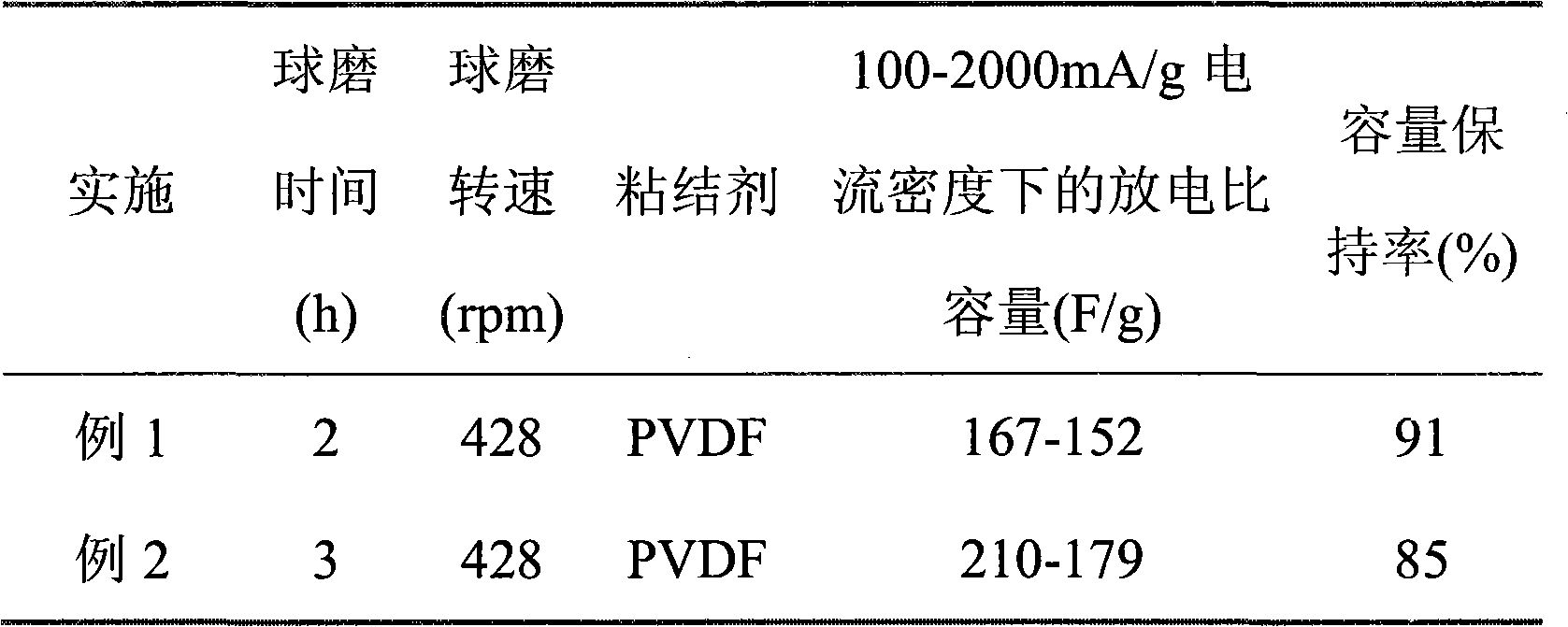

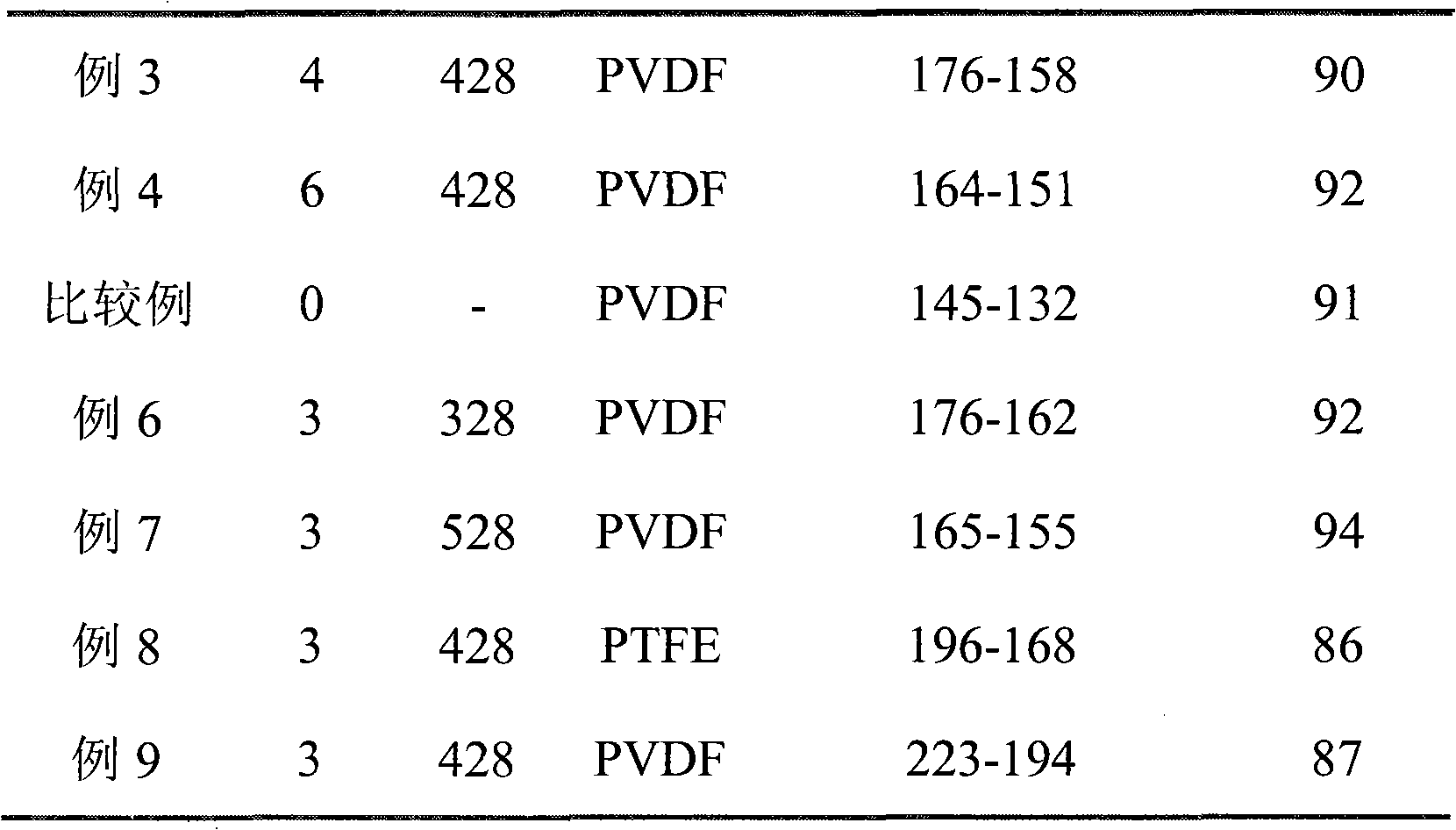

[0019] Weigh 0.5g of expanded graphite, mix it with 188.5g of grinding balls and place it in an agate ball ink tank, and ball mill for 2h at a speed of 428rpm in a planetary ball mill to obtain graphene nanosheets...

Embodiment 2

[0023] The operation method is the same as in Example 1, and the ball milling time is the graphene nanosheet electrode prepared for 3h. When the current density is gradually increased from 100mA / g to 2000mA / g, the stability after 100 charge-discharge cycles is measured under each current density. The discharge specific capacity is 210F / g-179F / g, and the capacity retention rate is 85%.

Embodiment 3

[0025] The operation method is the same as in Example 1, and the graphene nanosheet electrode prepared by the ball milling time is 4h. When the current density gradually increases from 100mA / g to 2000mA / g, the stable discharge specific capacity after 100 charge-discharge cycles at each current density It is 176F / g-158F / g, and the capacity retention rate is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com