Silicon monoxide composite cathode material for lithium ion battery, and preparation method thereof

A lithium-ion battery, silicon monoxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle performance and difficult industrialization, and achieve the effects of simple preparation process, low cost of raw materials, and inhibition of volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of silicon monoxide composite negative electrode material for lithium ion battery of the present invention comprises the following steps:

[0017] 1. According to the mass percentage, 4-20% of the catalyst precursor and 80-96% of silicon monoxide are stirred, mixed and dispersed in the organic solvent according to the existing technology to obtain a slurry; the volume mass of the organic solvent and the powder material The ratio is 100ml:2~15g, the stirring speed is 800~1500r / m, and the dispersion time is 2~5h.

[0018] The catalyst precursor is more than one of nickel acetate, nickel nitrate and nickel chloride.

[0019] The organic solvent is one or more of acetone, ethanol and tetrahydrofuran.

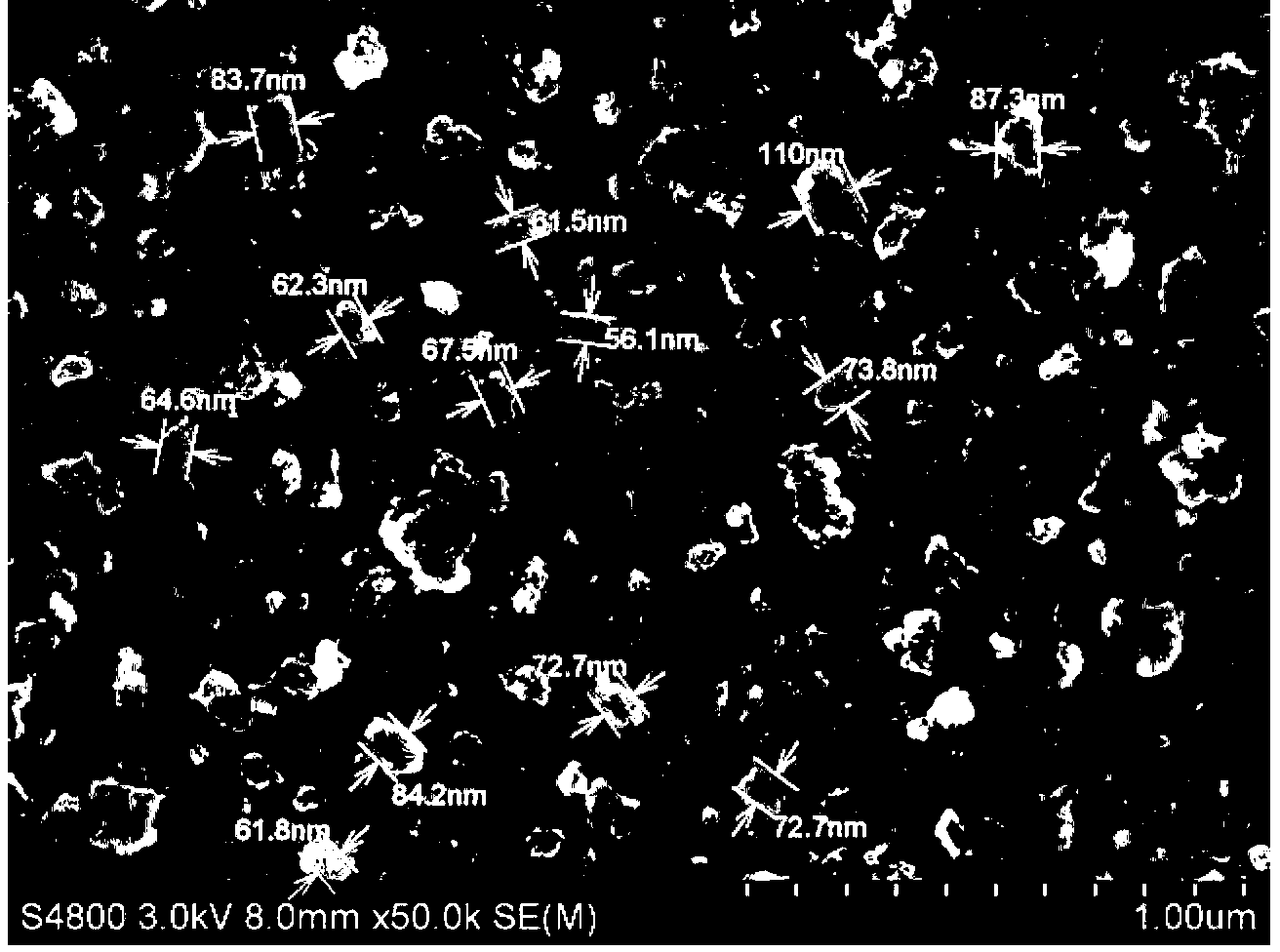

[0020] The particle size of silicon monoxide is 60-120nm.

[0021] 2. Use a spray dryer to spray dry the slurry to obtain a mixed powder material. The inlet temperature is 150-200°C, the outlet temperature is 75-120°C, and the atomization frequency is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com