Cathode material for lithium ion batteries and preparation method thereof

A lithium-ion battery and positive electrode material technology, applied in the field of lithium-ion battery positive electrode materials and their preparation, can solve the problems of battery capacity and rate performance decline, failure to achieve electrical performance, poor ion conductivity, etc., to maintain electrochemical inertness, improve Electron conductivity, effect of slow desorption reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

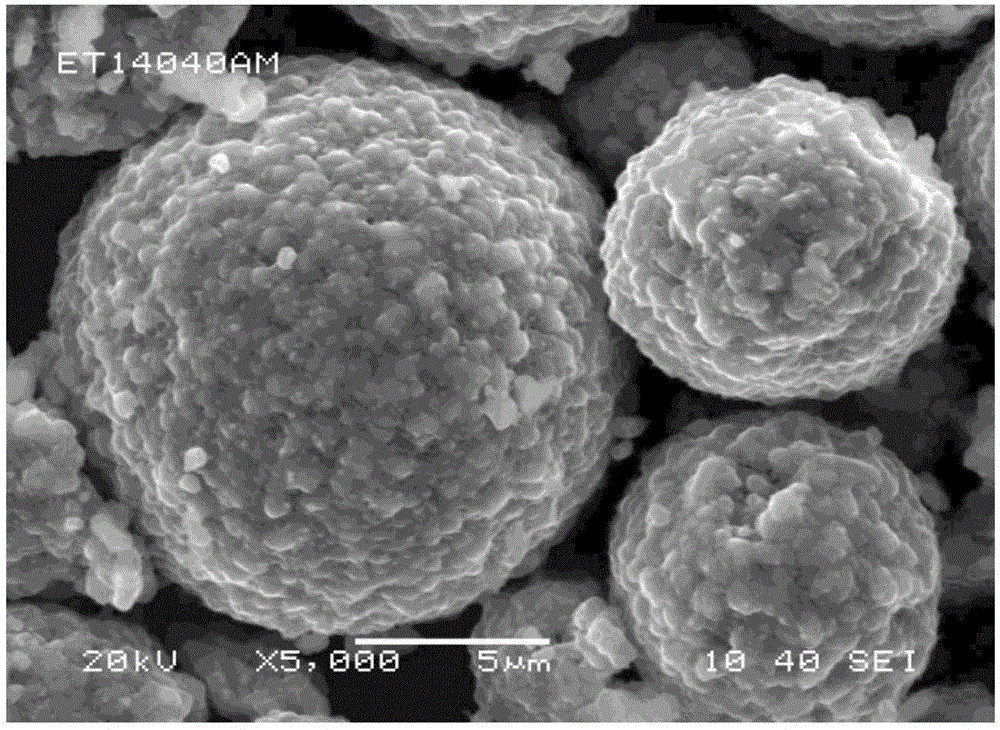

[0034] A lithium ion battery positive electrode material of the present invention is a core-shell structure, and the "core" is the positive electrode active material lithium cobaltate (LiCo 0.995 Ti0.002 Mg 0.003 o 2 ), the "shell" is containing point-like nano-Li 2 TiO 3 The carbon layer, the carbon layer is evenly coated on the surface of lithium cobalt oxide; where the nanometer Li 2 TiO 3 The quality of carbon accounts for 0.8wt% of positive electrode active material quality, and the quality of carbon in carbon layer accounts for 1.2wt% of positive electrode active material quality; ) is calcined and carbonized at high temperature, and the point-like nano-Li in the carbon layer 2 TiO 3 It is generated in situ in the carbon layer during the high-temperature calcination and carbonization process of phenolic resin.

[0035] The preparation method of above-mentioned lithium ion battery cathode material, comprises the following steps:

[0036] 1) Take 195.5g of cetyltri...

Embodiment 1 and comparative example 1

[0050] Table 1 embodiment 1 and comparative example 1,2 electrochemical properties

[0051]

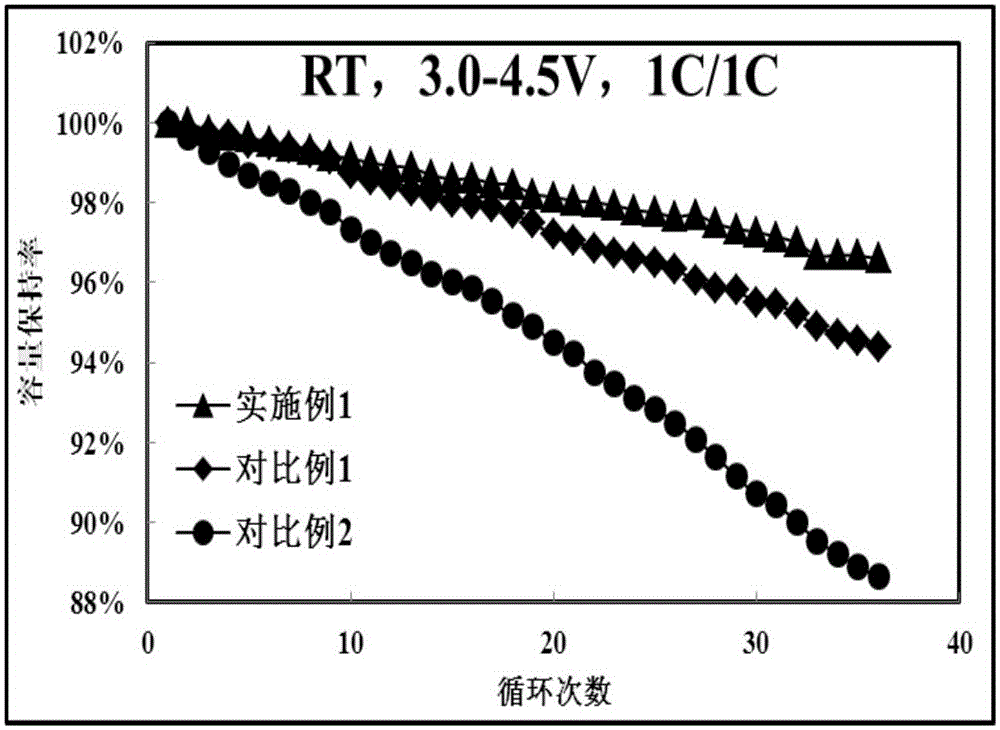

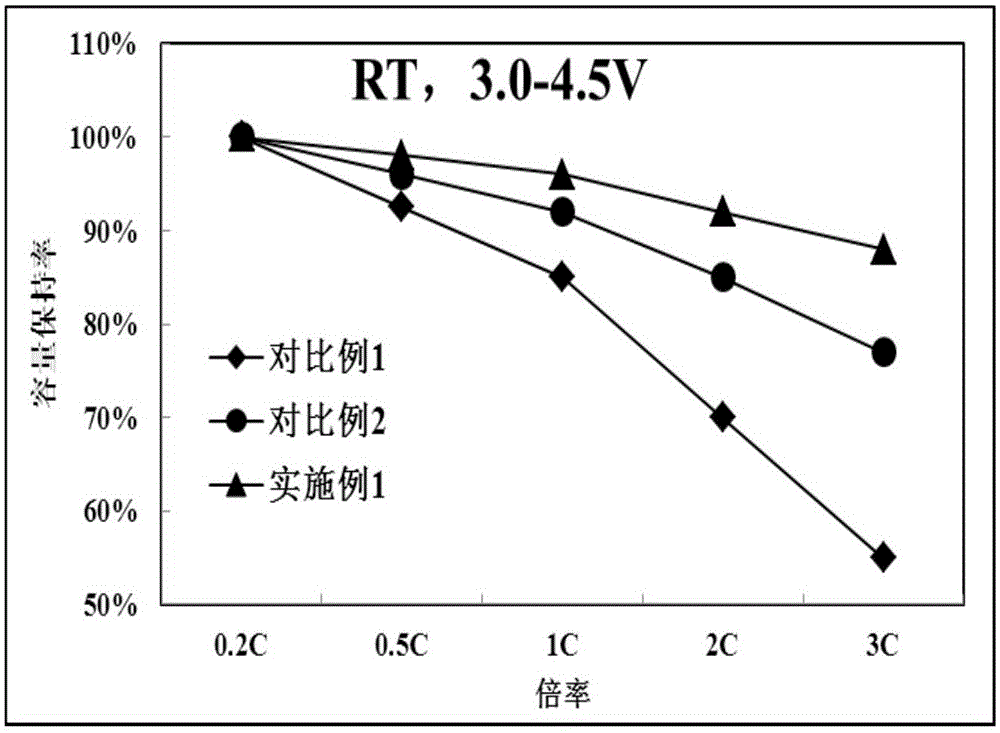

[0052] After the lithium-ion battery positive electrode material of Example 1 is made into a battery, at 25° C., its buckle charge performance is tested with 3.0 to 4.5 V, and its 1C discharge capacity is 191.2mAh / g; the rate 1C / 0.2C is 96.3%, and 3C / 0.2C is 88.5%; after 50 cycle tests, the capacity retention rate of the battery is 96.6%; the high-temperature storage performance of the full battery is tested at 3.0-4.35V, and the battery capacity retention rate at 85°C / 6h is 90.4%. The rate is 95.8%. From figure 1 , figure 2 As can be seen from Table 1: the lithium ion battery positive electrode material of embodiment 1 is compared with the battery capacity, cycle, rate and safety performance of the lithium ion battery positive electrode material modified by the single coating layer of comparative example 1 and comparative example 2. Significantly improved.

Embodiment 2

[0054] A lithium-ion battery positive electrode material of the present invention is a core-shell structure, and the "core" is the positive electrode active material lithium nickel cobalt manganese oxide (LiNi 0.6 co 0.2 mn 0.2 o 2 ), the "shell" is containing point-like nano-Li 2 TiO 3 The carbon layer, the carbon layer is uniformly coated on the surface of nickel-cobalt-lithium manganese oxide; the nano-Li 2 TiO 3 The quality of carbon accounts for 1.6wt% of positive electrode active material quality, and the quality of carbon in carbon layer accounts for 3.0wt% of positive electrode active material quality; It is calcined and carbonized at high temperature, and the point-like nano-Li in the carbon layer 2 TiO 3 It is generated in situ in the carbon layer during the high-temperature calcination and carbonization process of phenolic resin.

[0055] The preparation method of above-mentioned lithium ion battery cathode material, comprises the following steps:

[0056] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Magnification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com