Spherical hard carbon lithium ion battery cathode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low compaction density, low battery energy density, fast intercalation, and low delithiation ability, and achieve a simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

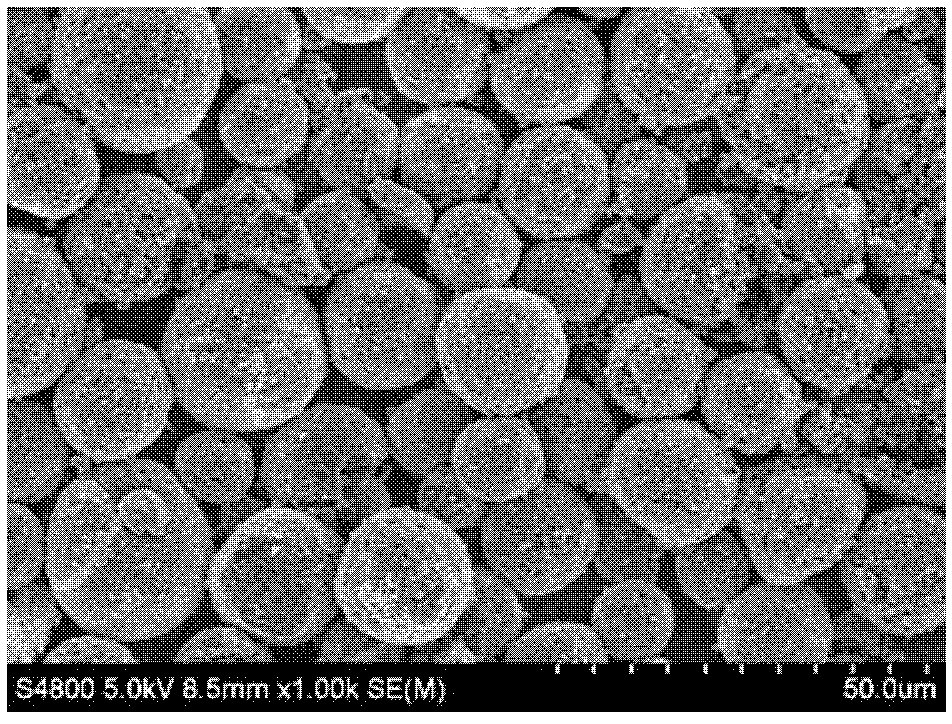

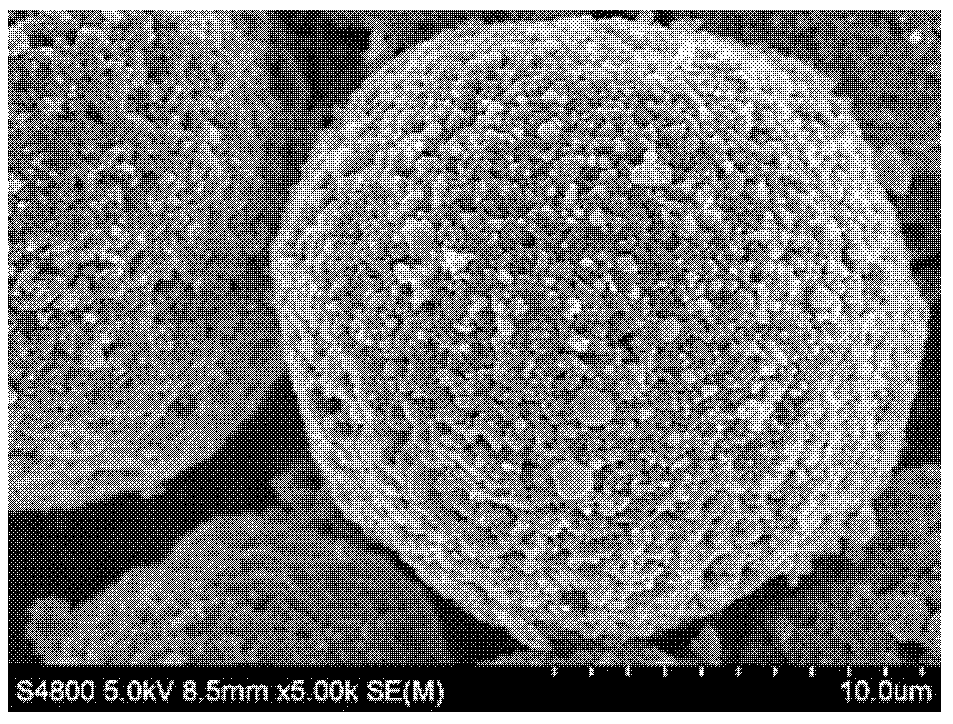

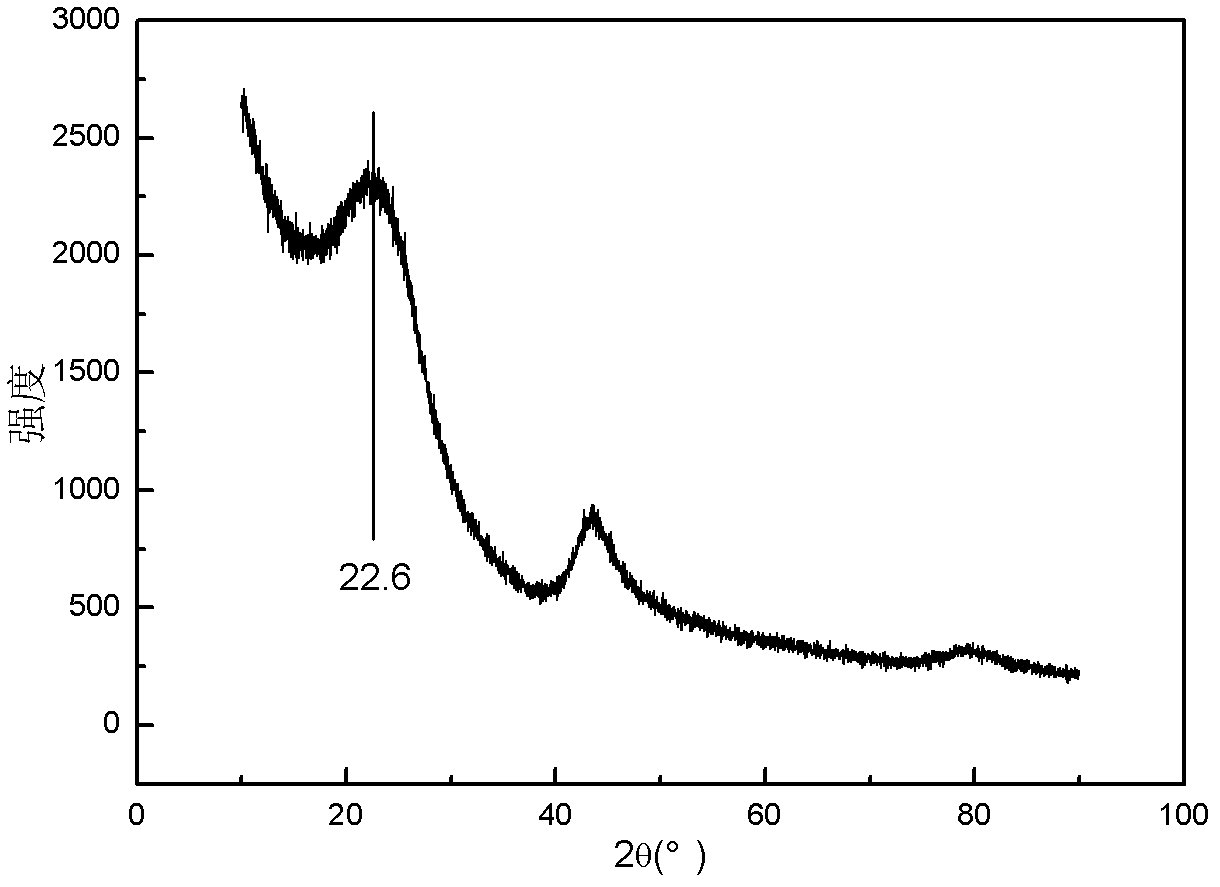

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The spherical hard carbon lithium-ion battery negative electrode material of the present invention uses hard carbon as a matrix, the matrix is coated with carbon materials, the carbon material precursor is 1 to 15% of the mass of the matrix, and the shape of the spherical hard carbon lithium-ion battery negative electrode material is spherical. , the particle size range is 1-30 μm, the hard carbon negative electrode material is amorphous carbon, the 002 peak is at 22.6°-23.8°, and the diffraction peak is broadened, the interlayer distance D of the 002 crystal plane 002 Between 0.360~0.480nm, the specific surface area is 1.0~73.2m 2 / g, the true density is 1.50~2.20g / cm 3 , the tap density is 0.95~1.52g / cm 3 , the compacted density is 1.08~1.63g / cm 3 .

[0024] The preparation method of spherical hard carbon lithium ion battery negative ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com