Silicon-carbon cathode material for lithium ion battery and manufacturing method thereof

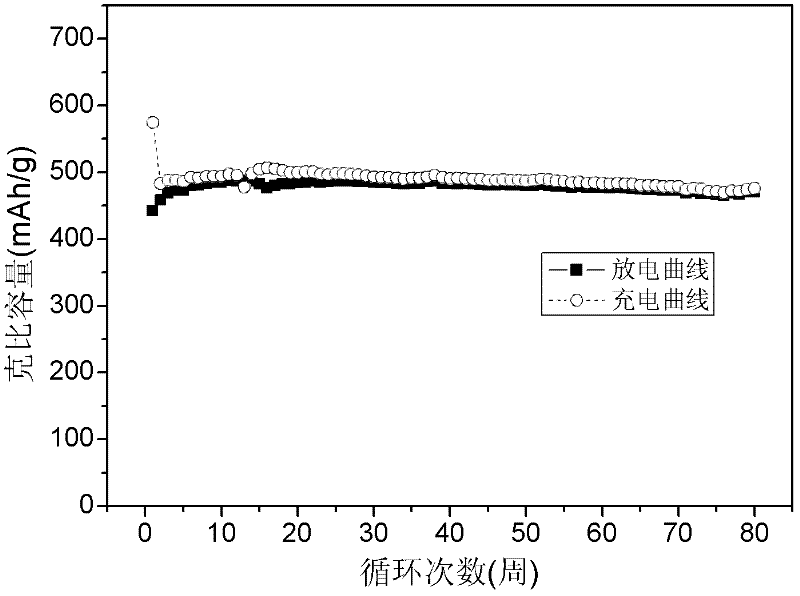

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve problems such as separation and impact on battery cycle performance, and achieve simple preparation process, low raw material cost, Effect of high specific gram capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

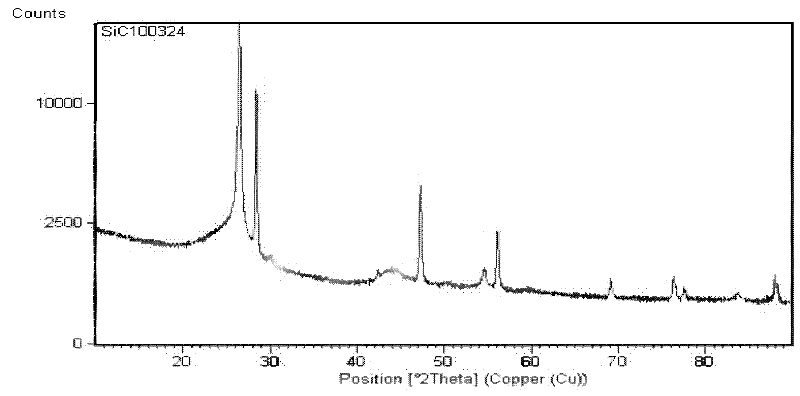

[0023] The preparation method of the silicon-carbon alloy negative electrode material that lithium-ion battery of the present invention is used comprises the following steps:

[0024] 1. According to the mass ratio, 5-95% of the nano-silicon powder with a particle size of 10-500nm, and 5-95% of the carbon material precursor of the coating layer, according to the mass ratio of the nano-silicon powder and the carbon material precursor to the solvent 1: 1-10, put into the solvent, rotate at 500-1500, stir for 1-3 hours to disperse evenly, dry the evenly dispersed slurry 1 according to the prior art until the solvent content is less than 1%, and obtain the compound 1.

[0025] The carbon material precursor is pitch, polyvinyl chloride, polyethylene, phenolic resin or stearic acid.

[0026] The solvent is more than one of water, alcohols, ketones, alkanes, esters, aromatics, N-methylpyrrolidone, dimethylamide, diethylformamide, dimethylsulfoxide and tetrahydrofuran .

[0027] 2. ...

Embodiment 1

[0040] 1. Weigh 10g of asphalt and 90g of nano-silicon powder with a particle size of 50-150nm into 100g of alcohol at a speed of 500 rpm, stir for 3 hours, and dry until the solvent content is less than 1%.

[0041] 2. At a heating rate of 10°C / min, until the heat treatment temperature does not exceed 750°C, keep the temperature for 10 hours, feed nitrogen with a purity of 99.9%, and a flow rate of 0.1L / min.M 3 .

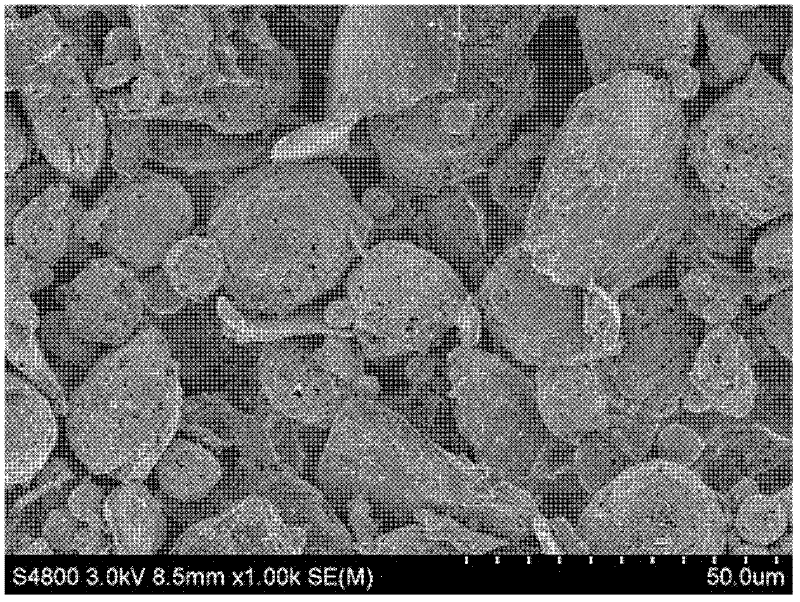

[0042] 3. Pulverize the composite material after heat treatment, and the particle size range after pulverization is 5-50um.

[0043] 4. According to the mass ratio of 1:50, put the crushed silicon composite material into the reaction reagent for treatment, and the reaction reagent is HF and HNO 3 The acid solution has a molar concentration of 0.1 mol / L and 10 mol / L respectively, the treatment time is 30 min, and the temperature is 10°C. After the reaction is completed, the treated powder is washed with deionized water until the pH value of the solution is 6-8. A...

Embodiment 2

[0052] 1. Weigh 95g of polyvinyl chloride and 5g of nano-silicon powder with a particle size of 50-110nm into 300g of alcohol at a speed of 1500 rpm, stir for 1 hour, and dry until the solvent content is less than 1%.

[0053] 2. With a heating rate of 1°C / min, to the heat treatment temperature of 300°C, keep the temperature constant for 6 hours, and feed argon with a flow rate of 0.1L / min.M 3 .

[0054] 3. Pulverize the composite material after heat treatment, and the particle size range after pulverization is 5-50um.

[0055] 4. According to the mass ratio of 1:1, put the crushed silicon composite material into the reaction reagent for treatment, and the reaction reagent is HF and HNO 3 The acid solution has a molar concentration of 25 mol / L and 16 mol / L, the treatment time is 5 min, and the temperature is 10°C. After the reaction is completed, the treated powder is washed with deionized water until the pH value of the solution is neutral. After being dried until the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com