Preparation method of nitrogen doped graphene and application of nitrogen doped graphene

A nitrogen-doped graphene and graphene technology, applied in the field of graphene, can solve the problems of nitrogen-doped graphene preparation limitations, high heating temperature, harsh preparation conditions, etc., to promote doping, increase pressure, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The embodiment of the present invention discloses a method for preparing nitrogen-doped graphene, and the specific steps are:

[0027] The carbon material and the compound containing active nitrogen element are placed in a closed container, heated to 100~300°C, and nitrogen-doped graphene is obtained after the reaction, the compound containing active nitrogen element is gas and / or solid, and the carbon The material is graphene or graphene oxide.

[0028] According to the present invention, in the above-mentioned process of preparing nitrogen-doped graphene, the graphene oxide is specifically prepared as follows:

[0029] Graphene oxide colloid with a concentration of 1mg / ml~15mg / ml is ultrasonicated for 0.5~2h, and freeze-dried to obtain graphene oxide. In order to ensure that the graphene oxide is broken more evenly and finely, the concentration of the graphene oxide is preferably 5-10 mg / ml, and the time of the ultrasound is preferably 1-1.5 h. The above-mentioned p...

Embodiment 1

[0039] Take 100ml of graphene oxide colloid with a concentration of 1mg / ml, mix it with 1g of ammonium bicarbonate evenly, freeze-dry, place the obtained powder in a sealed container and heat to 100°C, and keep it warm for 5h. After the reaction is finished, the reactor is opened after being cooled to room temperature, and the black product nitrogen-doped graphene is obtained.

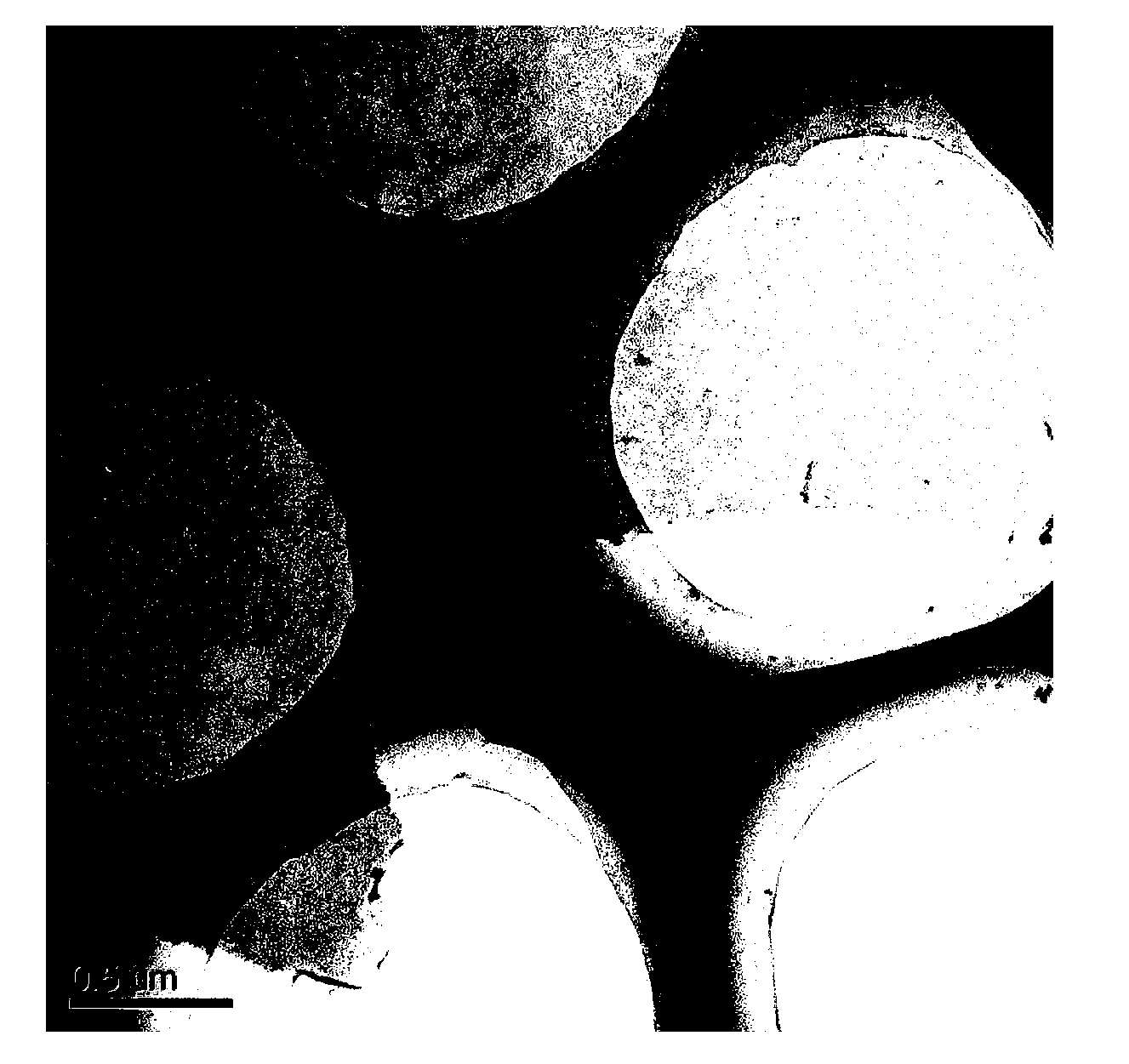

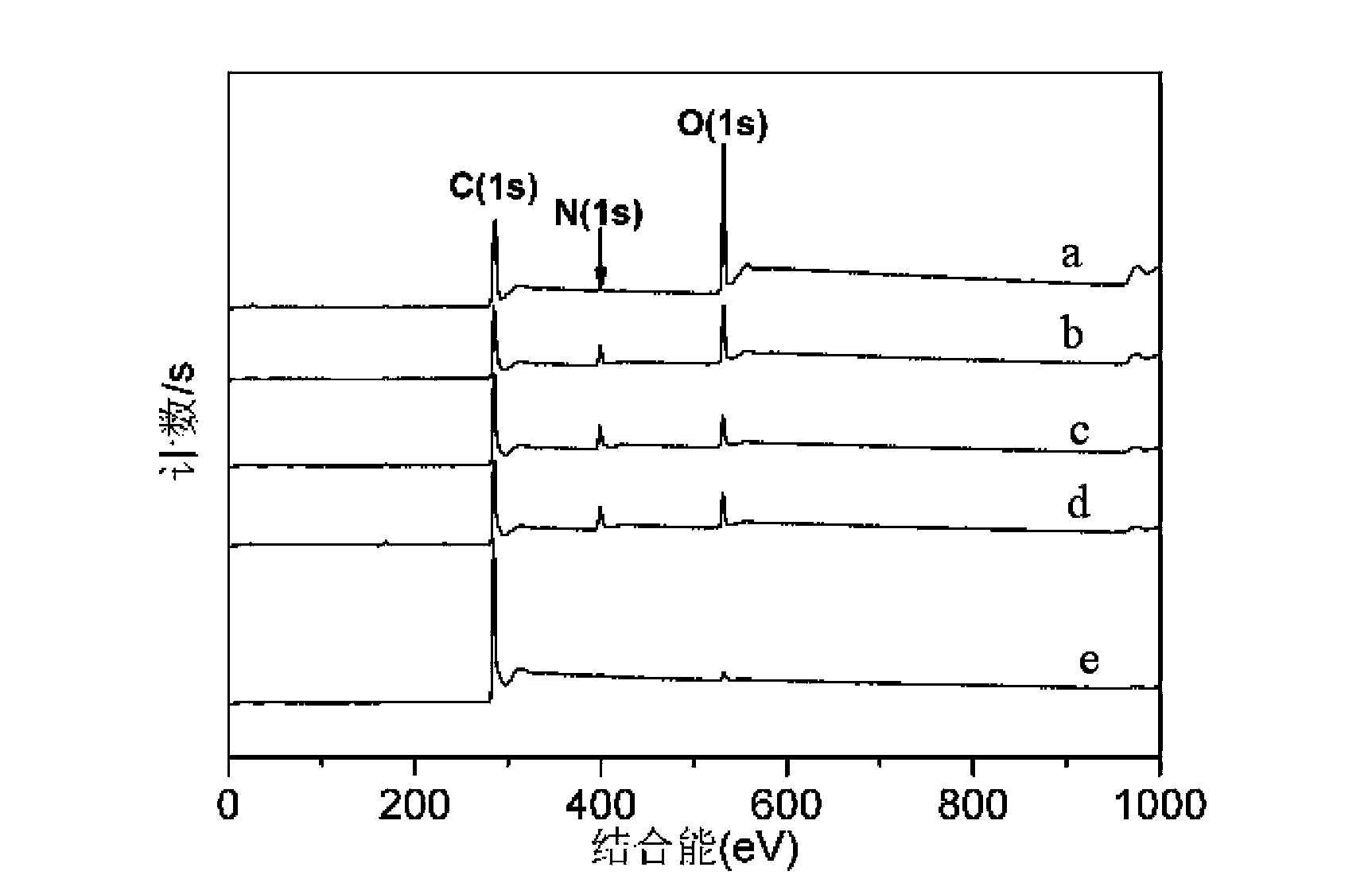

[0040] Such as figure 1 as shown, figure 1 For the transmission electron microscope figure of the nitrogen-doped graphene prepared in embodiment 1, by figure 1 It can be seen that the nitrogen-doped graphene sheet structure obtained by the present invention is complete. Such as figure 2 as shown, figure 2 is the TEM selected area electron diffraction pattern of nitrogen-doped graphene, by figure 2 It can be seen that the nitrogen-doped graphene lattice structure obtained by the present invention is complete. Such as image 3 as shown, image 3 Be X-ray photoelectron spectrum curve, curve a a...

Embodiment 2

[0042] Take 100ml of graphene oxide colloid with a concentration of 5mg / ml, mix it with 100mg of ammonium carbonate evenly, freeze-dry, place the obtained powder in a sealed container and heat to 200°C, and keep it warm for 10h. After the reaction is finished, the reactor is opened after being cooled to room temperature, and the black product nitrogen-doped graphene is obtained.

[0043] as attached image 3 as shown, image 3 For the X-ray photoelectron spectrum curve of the nitrogen-doped graphene prepared in Example 2, curve c in the figure is the X-ray photoelectron spectrum curve of the nitrogen-doped graphene prepared in the present embodiment, as can be seen from curve c, after reacting for 10h , an obvious nitrogen doping peak appeared in graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com