Low-dark-current high-sensitivity photoelectric detector structure and manufacturing method thereof

A photodetector and high-sensitivity technology, applied in the direction of chemical instruments and methods, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of production difficulty and cost increase, hinder side wall leakage, photocurrent influence, etc., to achieve Reduce the overlay and etching process, the process is simple, and the effect of improving device sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

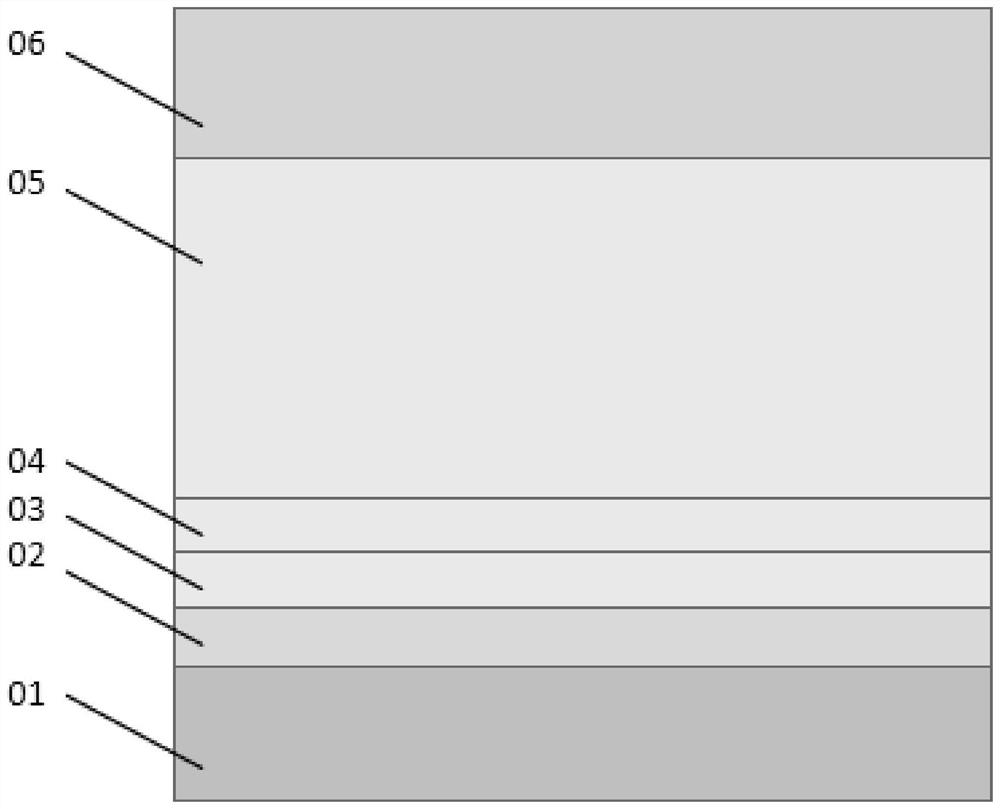

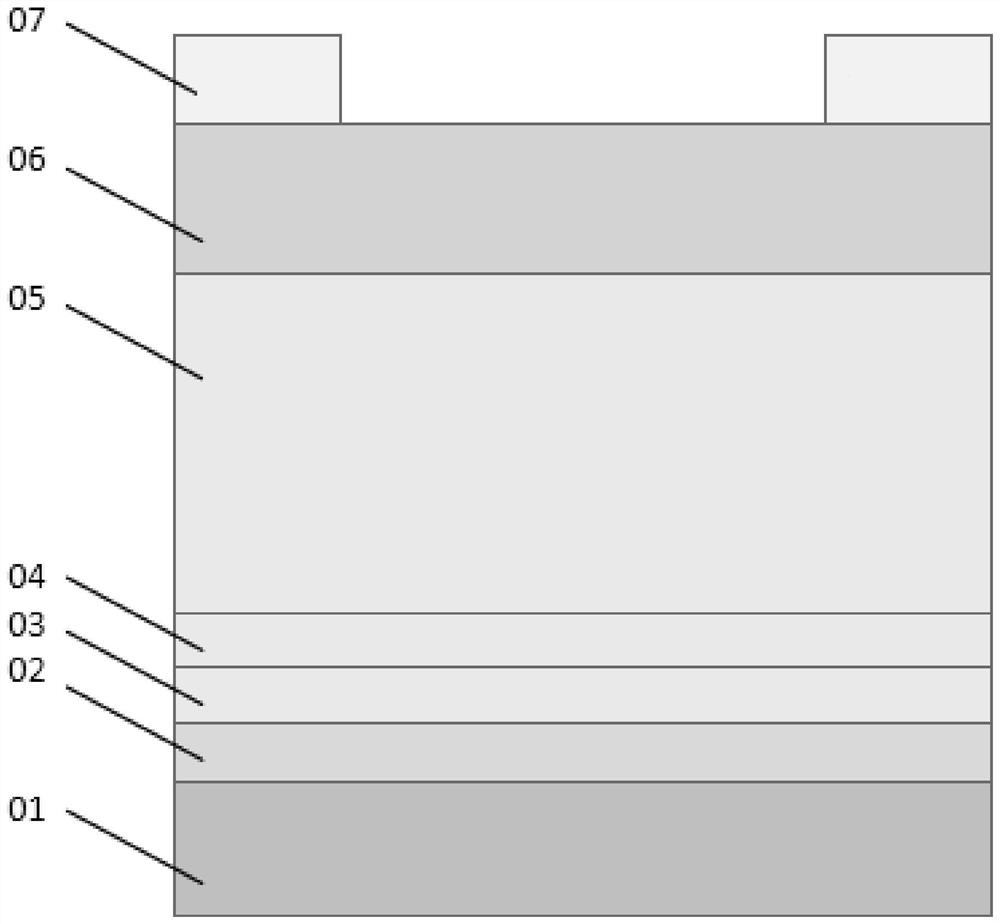

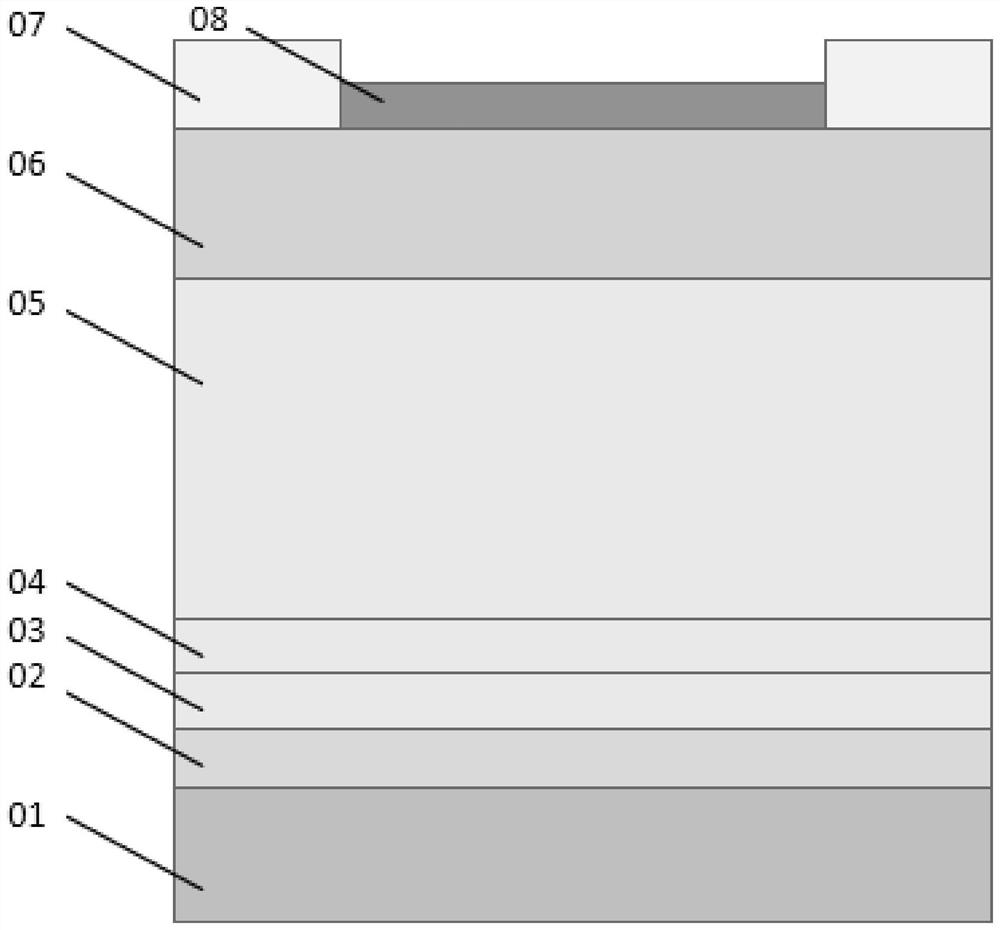

[0032] Example: such as image 3 As shown, a low dark current high-sensitivity photodetector structure includes an epitaxial wafer, the epitaxial wafer includes an InP substrate 01, and a buffer layer 02 and a lower ohmic contact layer 03 are sequentially deposited on the top of the InP substrate 01 from bottom to top. , transition layer 04, absorption layer 05 and window layer 06, upper ohmic contact layer 08 and insulating layer 08 are arranged above the window layer 06; upper ohmic contact layer 08 and insulating layer 07 are located in the same layer, insulating layer 07 is divided into two partly and respectively located on both sides of the upper ohmic contact layer 08 . The thickness of the insulating layer 07 is greater than the thickness of the upper ohmic contact layer 08 . Both parts of the insulating layer 07 have the same structure.

[0033] Its manufacturing method comprises the following steps:

[0034] Step 1: Use InP as the growth substrate, put it into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com