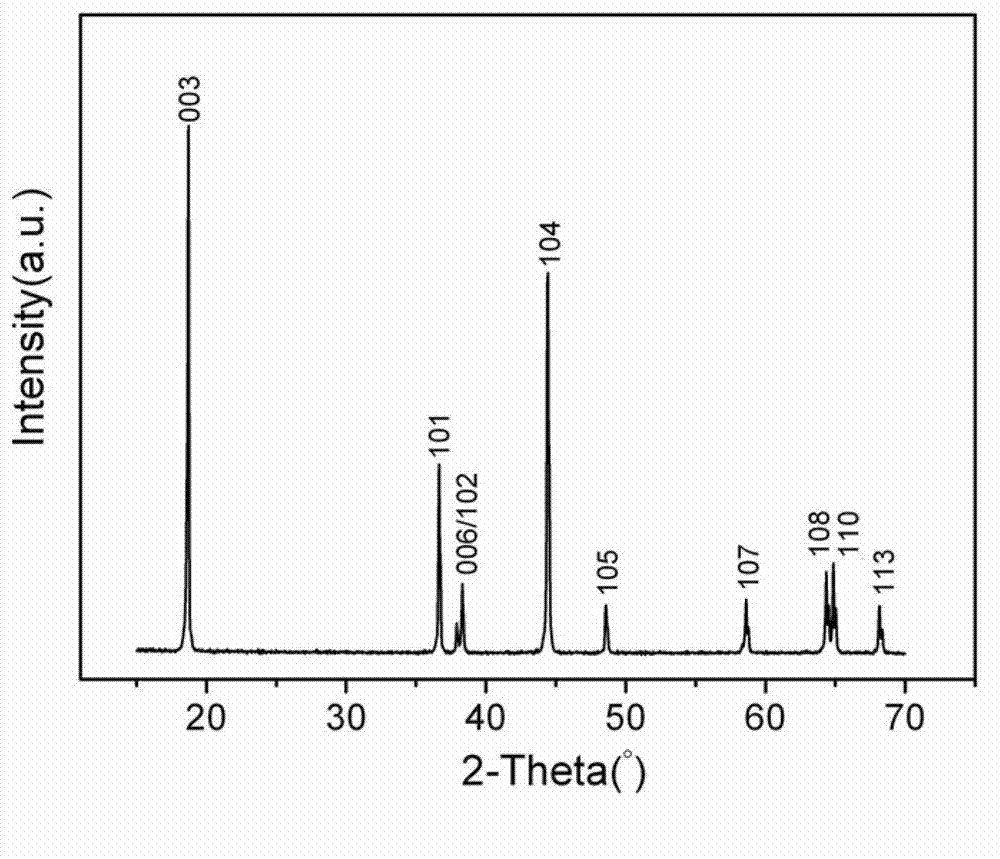

Method for preparing coated lithium ion battery cathode material of lithium nickel manganese oxide

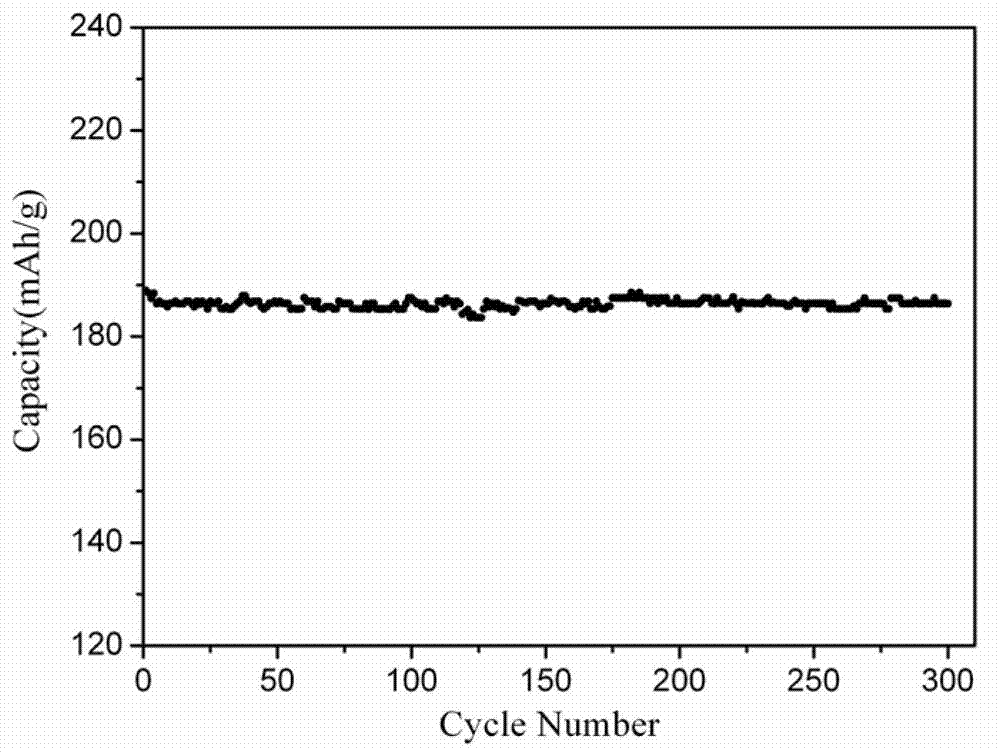

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as fast capacity decay and poor cycle performance, achieve reduced temperature and reaction time, high tap density, and avoid elements. The effect of uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

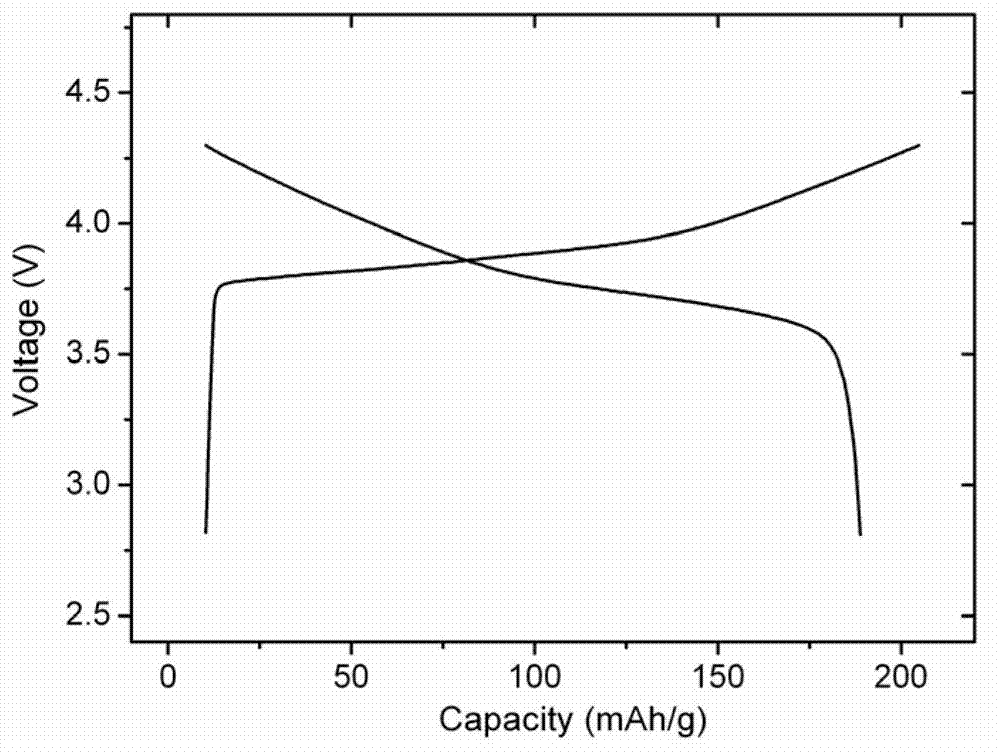

[0023] (1) The nickel-manganese mixed solution (the molar ratio of nickel and manganese metal ions is 3:1) that is configured as a total metal concentration of 2mol / L, 3mol / L ammonia solution and 3mol / L sodium hydroxide solution are pumped continuously with a metering pump into a reactor with a stirring device; the reaction temperature range is controlled at 50°C, the pH value range is 9.0, and the stirring frequency is 100Hz until the pH value of the reaction system reaches 10.5; the precipitate generated by the reaction is introduced into a centrifuge and thrown Dry, and wash with 45°C deionized water until the pH value reaches 11.0; dry the washed precipitate in an oven at 105°C for 6h to remove moisture, and obtain the spherical hydroxide precursor Ni 0.75 mn 0.25 (OH) 2 .

[0024](2) Mix the prepared precursor with the mixed lithium source (the molar ratio is: lithium carbonate: lithium hydroxide = 0.60:0.40) according to the molar ratio of Li: (Ni+Mn) = 1.06:1, and mix...

Embodiment 2

[0027] (1) The nickel-manganese mixed solution with a total metal concentration of 2mol / L (the molar ratio of nickel and manganese metal ions is 1:1), 3mol / L ammonia solution and 3mol / L sodium hydroxide solution are pumped continuously with a metering pump into a reactor with a stirring device; the reaction temperature range is controlled at 50°C, the pH range is 8.5, and the stirring frequency is 100Hz until the pH value of the reaction system reaches 10.0; the precipitate generated by the reaction is introduced into a centrifuge and thrown Dry, and wash with 45°C deionized water until the pH value reaches 10.5; dry the washed precipitate in an oven at 110°C for 6h to remove moisture, and obtain the spherical hydroxide precursor Ni 0.5 mn 0.5 (OH) 2 .

[0028] (2) Mix the prepared precursor with the mixed lithium source (the molar ratio is: lithium carbonate: lithium hydroxide = 0.50:0.50) according to the molar ratio of Li: (Ni+Mn) = 1.05:1, and mix them evenly at 425°C P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com