Method for rapidly dissolving copper in electrolytic copper foil manufacturing process

A manufacturing process, electrolytic copper foil technology, applied in electrolytic process, chemical instruments and methods, electroforming, etc., can solve the problems of slow copper dissolution speed, achieve the effect of simple equipment, simple dissolution method, and inhibition of disproportionation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

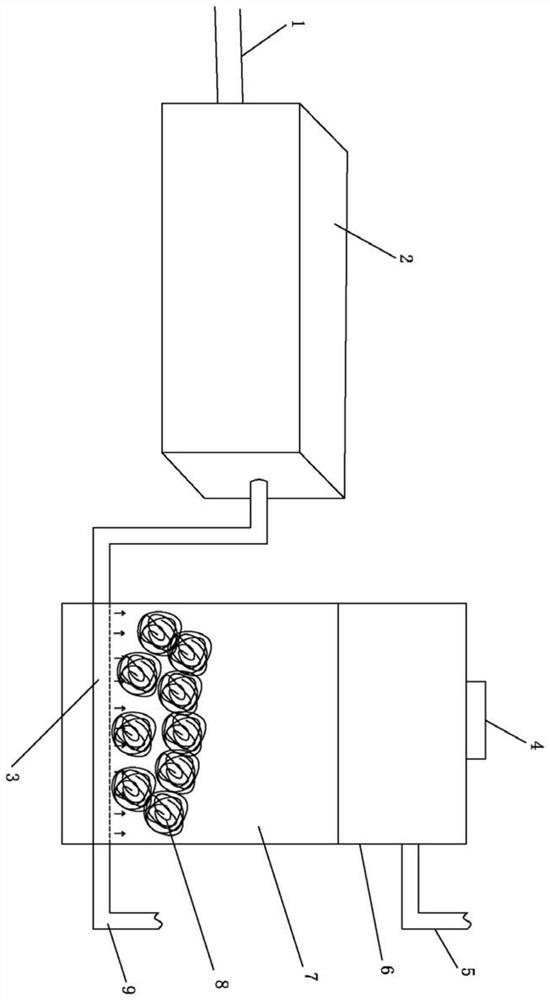

Image

Examples

Embodiment 1

[0019] Embodiment 1 Place 100g of copper cables in 600ml of 100g / L sulfuric acid aqueous solution, feed into nano-oxygen bubbles for stirring, and make copper accelerate the oxidation and dissolution of copper under the environment of oxygen-rich sulfuric acid aqueous solution, and ensure copper dissolution The temperature of the tank was 50°C. The dissolution rate of copper and the concentration of monovalent copper ions are listed in Table 1.

Embodiment 2

[0020] Embodiment 2 Place 100g of copper cables in 600ml of 100g / L sulfuric acid aqueous solution, feed into nano-oxygen bubbles for stirring, and accelerate the oxidation and dissolution of copper under the environment of oxygen-rich sulfuric acid aqueous solution, and ensure copper dissolution The temperature of the tank was 60°C. The dissolution rate of copper and the concentration of monovalent copper ions are listed in Table 1.

Embodiment 3

[0021] Embodiment 3 Place 100g of copper cables in 600ml of 100g / L sulfuric acid aqueous solution, feed into nano-oxygen bubbles for stirring, and accelerate the oxidation and dissolution of copper under the environment of oxygen-rich sulfuric acid aqueous solution, and ensure copper dissolution The temperature of the tank was 65°C. The dissolution rate of copper and the concentration of monovalent copper ions are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com