Modified sodium manganate material as well as preparation method and application thereof

A technology of sodium manganate and sodium salt, applied in the field of preparation of water-based ion batteries, can solve problems such as poor cycle stability of water-based batteries, and achieve the effects of easy mass production, low cost and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

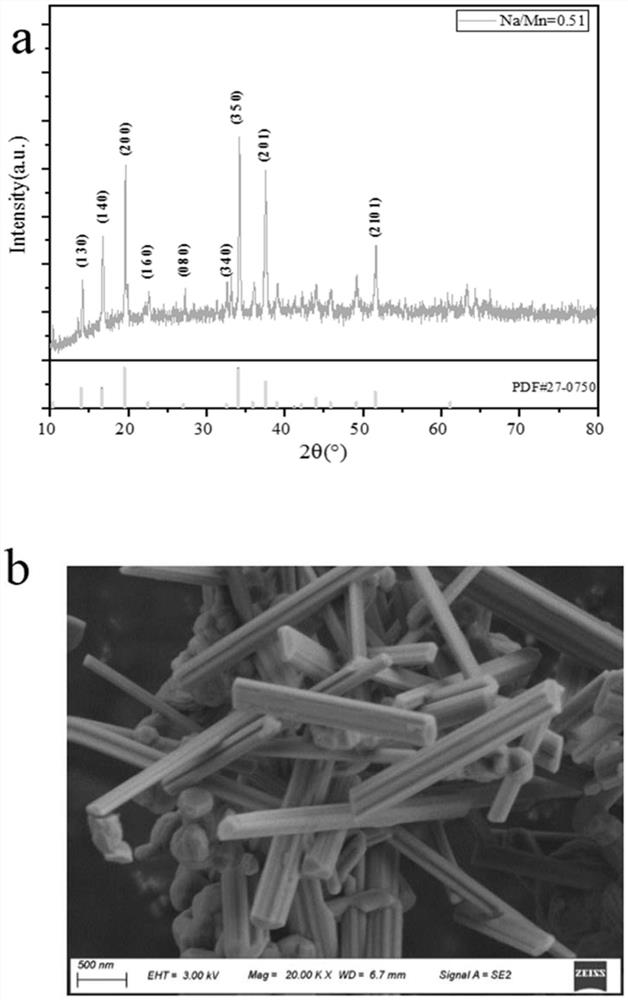

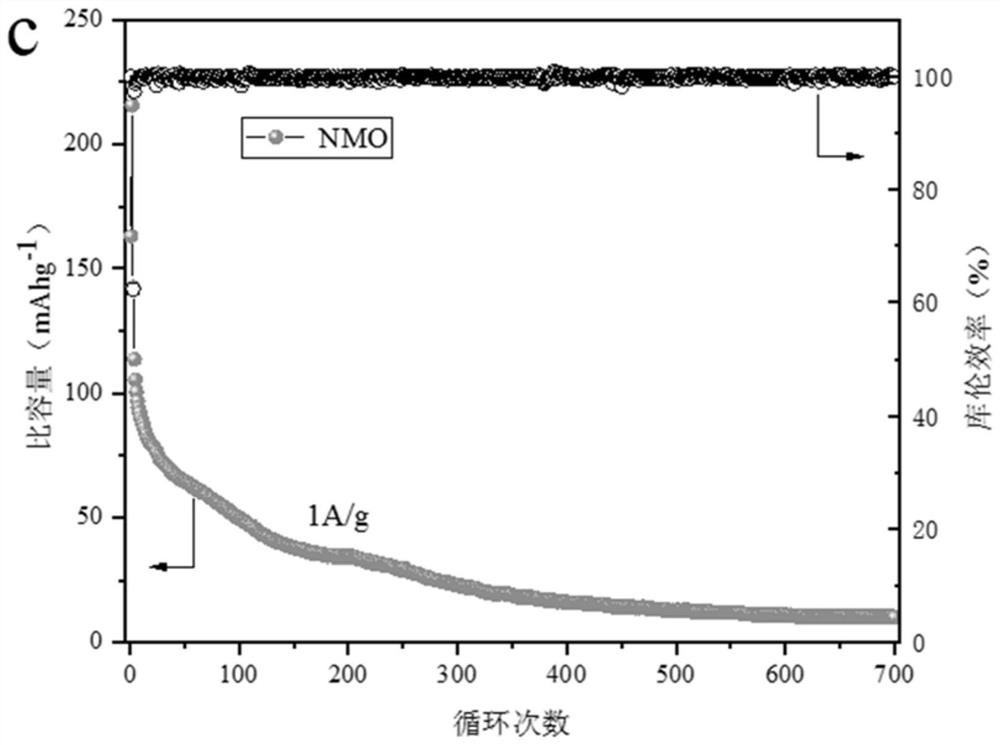

Embodiment 1

[0040] A preparation method of modified sodium manganate material, comprising the following steps:

[0041] Step 1: The tetra-n-butoxide titanium (IV) (C 16 H 36 O 4 Ti, Ti=0.11), anhydrous sodium carbonate (Na2 CO 3 ), manganese acetate tetrahydrate ((CH 3 COO) 2 Mn·4H 2 O) and citric acid were mixed and dissolved in ultrapure water, heated at 80 °C for 4 h, stirred evenly, and then evaporated deionized water to obtain a gel; the molar ratio of coupling agent to the metal ion in the transition metal salt was 1;

[0042] The molar ratio of sodium salt to transition metal salt is 0.51; the molar ratio of titanium salt to manganese salt is 0.11;

[0043] Step 2: put the gel into a preheated oven at 80°C and dry for 12 hours, and obtain a powdered precursor after drying;

[0044] Step 3: After grinding the powdered precursor, put it into a tube furnace for firing at 300°C for 8 hours in an air atmosphere, perform the first firing treatment, and then burn it at 900°C for 9 ...

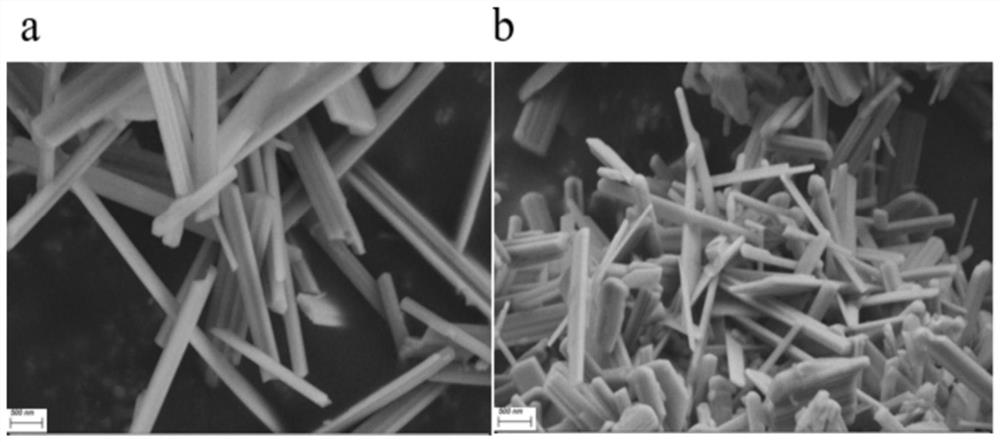

Embodiment 2

[0046] A preparation method of modified sodium manganate material, comprising the following steps:

[0047] Step 1: The tetra-n-butoxide titanium (IV) (C 16 H 36 O 4 Ti, Ti=0.22), anhydrous sodium carbonate (Na 2 CO 3 ), manganese acetate tetrahydrate ((CH 3 COO) 2 Mn·4H 2 O) and citric acid were mixed and dissolved in ultrapure water, heated at 80°C for 5h, stirred evenly, evaporated deionized water to obtain gel; the molar ratio of coupling agent to metal ions in transition metal salt was 1;

[0048] The molar ratio of sodium salt to transition metal salt is 0.51; the molar ratio of titanium salt to manganese salt is 0.22;

[0049] Step 2: put the gel into a preheated oven at 80°C and dry for 12 hours, and obtain a powdered precursor after drying;

[0050] Step 3: After grinding the powdered precursor, put it into a tube furnace for firing at 300°C for 8 hours in an air atmosphere, perform the first firing treatment, and then burn it at 900°C for 9 hours after grindi...

Embodiment 3

[0052] A preparation method of modified sodium manganate material, comprising the following steps:

[0053] Step 1: The tetra-n-butoxide titanium (IV) (C 16 H 36 O 4 Ti, Ti=0.33), anhydrous sodium carbonate (Na 2 CO 3 ), manganese acetate tetrahydrate ((CH 3 COO) 2 Mn·4H 2 O) and citric acid were mixed and dissolved in ultrapure water, heated at 80 °C for 12 h, stirred evenly, and evaporated deionized water to obtain a gel;

[0054] Among them, the molar ratio of the coupling agent to the metal ion in the transition metal salt is 1; the molar ratio of the sodium salt to the transition metal salt is 0.51; the molar ratio of the titanium salt to the manganese salt is 0.33;

[0055] Step 2: put the gel into a preheated oven at 80°C and dry for 12 hours, and obtain a powdered precursor after drying;

[0056] Step 3: After grinding the powdered precursor, put it into a tube furnace for firing at 300°C for 8 hours in an air atmosphere, perform the first firing treatment, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com