Refrigeration cycle apparatus

一种制冷循环、制冷剂的技术,应用在制冷机、制冷组件、制冷和液化等方向,能够解决上升、性能低下等问题,达到抑制歧化反应、高性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

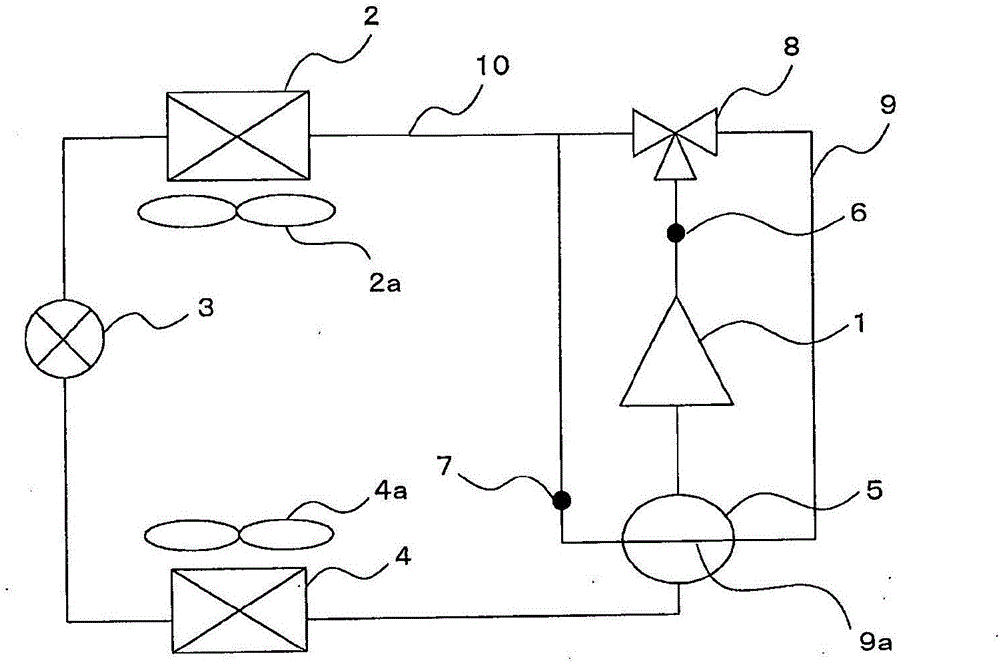

[0042] First, the configuration of the refrigeration cycle apparatus in Embodiment 1 will be described.

[0043] figure 1 It is a schematic configuration diagram of the refrigeration cycle apparatus in Embodiment 1.

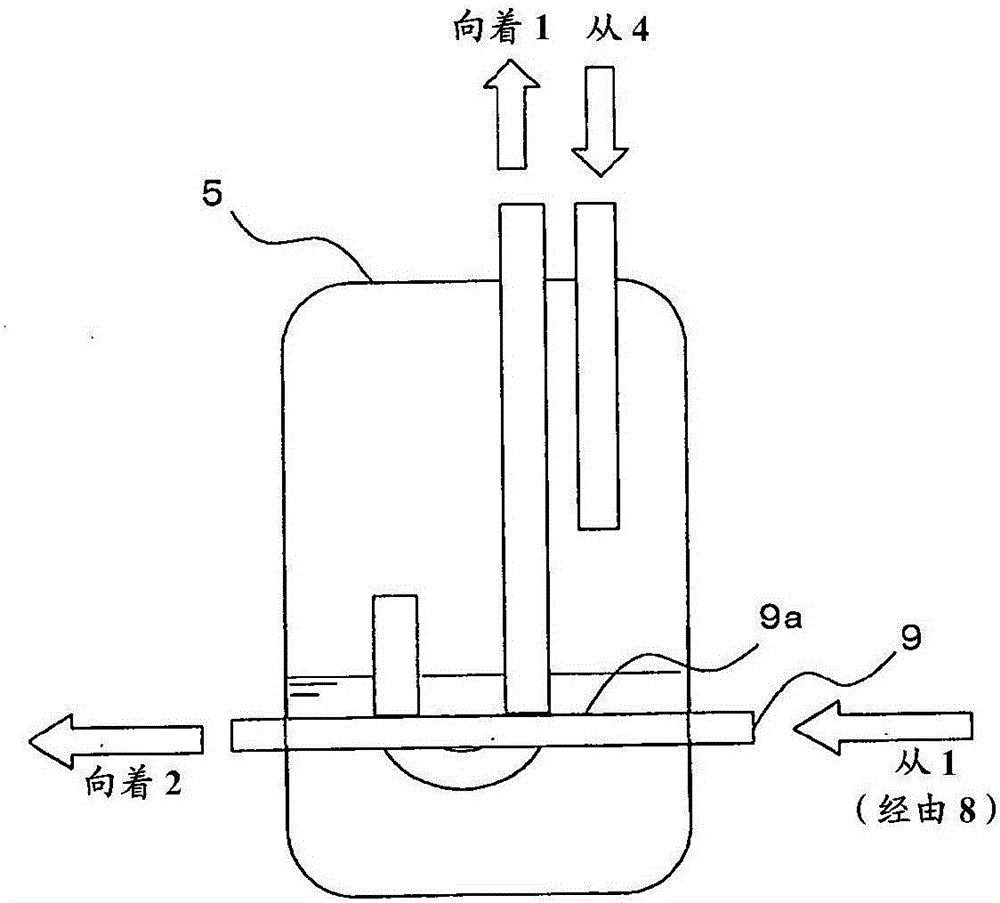

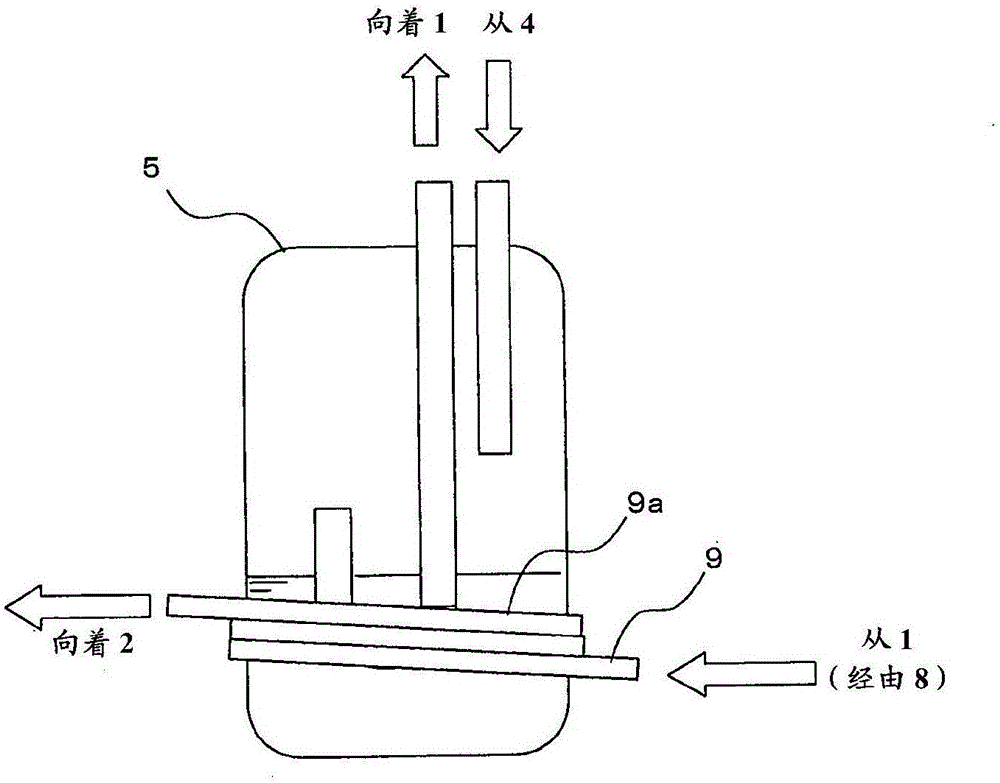

[0044] like figure 1 As shown, the refrigeration cycle device in Embodiment 1 has a main path that sequentially connects the compressor 1, the condenser 2, the expansion valve 3, the evaporator 4, and the accumulator 5 (corresponding to the gas-liquid separator of the present invention). 10. In addition, the refrigerating cycle device has a bypass path 9 branched from the discharge side of the compressor 1 of the main path 10 , passes through the accumulator 5 via the three-way valve 8 , and communicates with the discharge side of the main path 10 . The inlet side of the condenser 2 is connected. And, these respective structural elements are connected by refrigerant piping.

[0045] In addition, the bypass path 9 and the heat exchange portion 9a of the accum...

Embodiment approach 2

[0090] Next, the structure of the refrigeration cycle apparatus in Embodiment 2 is demonstrated.

[0091] Figure 10 It is a schematic configuration diagram of the refrigeration cycle apparatus in Embodiment 2.

[0092] In the refrigeration cycle apparatus of the second embodiment, the basic structure is the same as that of the first embodiment, but there is a difference in that a four-way valve 11 is provided on the downstream side of the three-way valve 8, and the flow direction of the refrigerant can be switched, Therefore, only this point will be described. In addition, the same reference numerals are assigned to the same constituent elements as in Embodiment 1 (in Embodiment 1, the heat exchanger is divided into a condenser 2 and an evaporator 4, and in Embodiment 2, by switching the four-way valve 11, the condenser 2 can sometimes function as an evaporator, and evaporator 4 can sometimes function as a condenser).

[0093] Next, the operation of the refrigeration cycle...

Embodiment approach 3

[0103] Next, the structure of the refrigeration cycle apparatus in Embodiment 3 is demonstrated.

[0104] Figure 13 It is a schematic configuration diagram of the refrigeration cycle apparatus in Embodiment 3.

[0105] In the refrigeration cycle apparatus in Embodiment 3, the basic configuration is the same as in Embodiment 1, but in the initial state of starting the operation, the discharge refrigerant of the compressor 1 is supplied to the accumulator 5, There is also a compressor heating mechanism 13 and an accumulator heating unit 14 in places where the refrigerant tends to accumulate when the compressor 1 and the accumulator 5 are stopped, and they are different in that they can be heated.

[0106] As the compressor heating mechanism 13 , for example, a heating mechanism that heats the compressor 1 by energizing (constrained energization) the motor coil without driving the motor inside the compressor 1 can be used, for example.

[0107] In addition, the outer surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com