Method and device for preparing acetonebutanol by utilizing adsorption carrier fermentation

An acetone-butanol and acetone-butanol fermentation technology, which is applied in the field of fermentation engineering, can solve the problems of affecting the permeability of polymer substrates, complex immobilization methods, and increasing the probability of bacterial infection, so as to improve the composition ratio and increase the contact ratio. Surface, the effect of improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

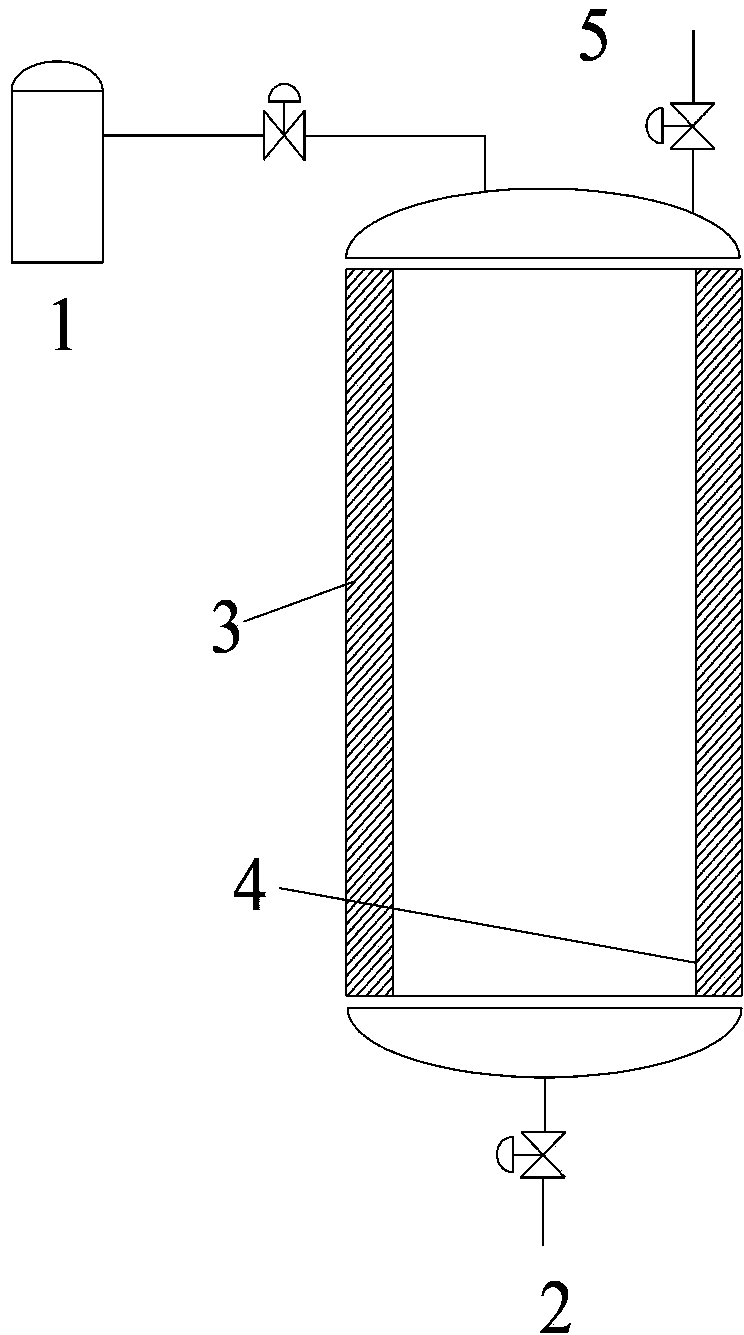

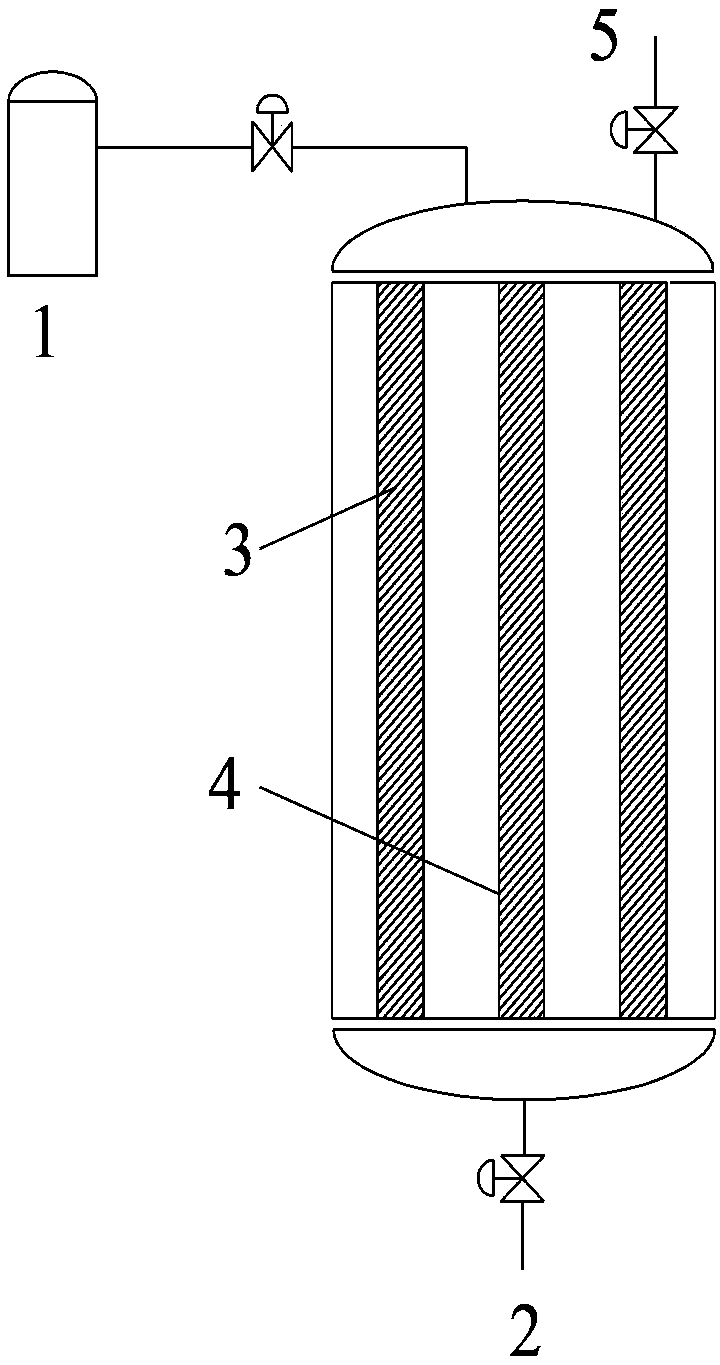

Image

Examples

Embodiment 1

[0024] Using 80g / L glucose as the substrate and steam explosion-delignification pretreated corn stalks as the carrier, the culture medium was sterilized, inoculated with Clostridium acetobutylicum ATCC 824, and fermented for 72 hours to fully utilize the glucose. After fermentation, the discharge port is opened to obtain a fermentation liquid. Compared with the control liquid fermentation experiment, the total solvent production was increased by 57% in the adsorption carrier fermentation.

Embodiment 2

[0026] With 54g / L xylose as the substrate and non-woven fabric as the carrier, after the medium was sterilized, Clostridium acetobutylicum ATCC 824 was inoculated and fermented for 72 hours to fully utilize xylose. After fermentation, the discharge port is opened to separate the fermentation broth and the adsorption carrier. Compared with the control liquid fermentation experiment, the total solvent production was increased by 27% in the adsorption carrier fermentation.

Embodiment 3

[0028] With 60g / L glucose as the substrate and polyurethane foam as the carrier, Clostridium acetobutylicum ATCC 824 was inoculated after sterilization and fermented for 72 hours to fully utilize glucose. After fermentation, the discharge port is opened to obtain a fermentation liquid. Compared with the control liquid fermentation experiment, the total solvent production was increased by 39% in the adsorption carrier fermentation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com