Adsorbing resin for removing impurities from chlorosilane and preparation method of adsorbing resin

A technology of adsorption resin and chlorosilane, which is applied in the field of adsorption resin for chlorosilane impurity removal and its preparation, can solve the problems of reduced purity of chlorosilane and increased production cost, and achieves the effect of strong adsorption capacity and reduced disproportionation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

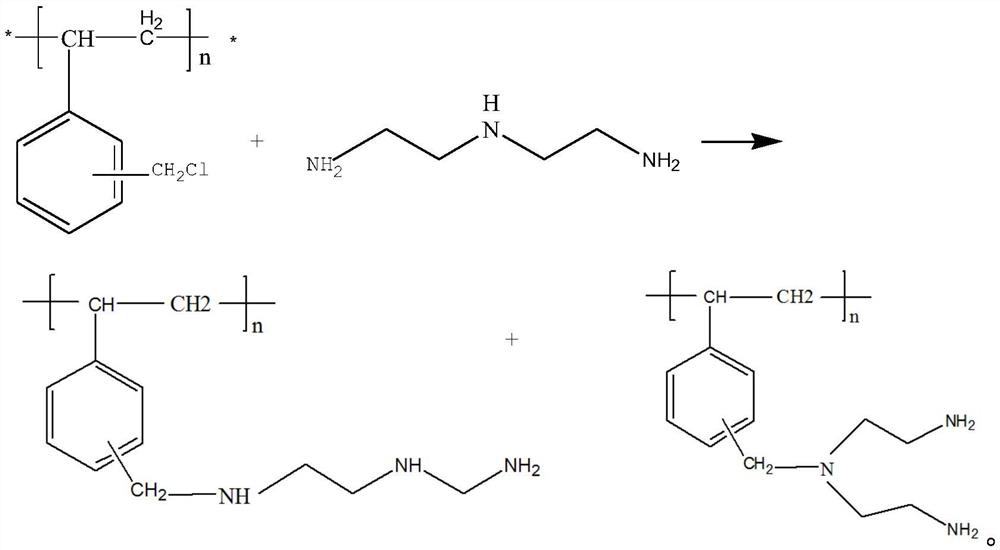

[0015] The embodiment of the present application provides a method for preparing an adsorption resin for impurity removal of chlorosilanes, including:

[0016] The chlorine ball is swelled in an organic solvent and then reacted with a reactant to obtain an initial product; the reactant contains polyamines, and the initial product contains tertiary amines.

[0017] Exemplarily, the chlorine spheres are chloromethylated polystyrene microspheres. Optionally, the organic solvent includes any one of toluene, tetrahydrofuran and 1,2-dichloroethylene. Chloromethylated polystyrene microspheres can swell well in toluene tetrahydrofuran or 1,2-dichloroethylene solution.

[0018] Among them, after the chlorine ball is swelled in the organic solvent, it can undergo a cross-linking reaction with the reactant containing polyamine, and the compound modification of polyamine is introduced on the chlorine ball. It should be noted that the initial product contains both the initial resin and c...

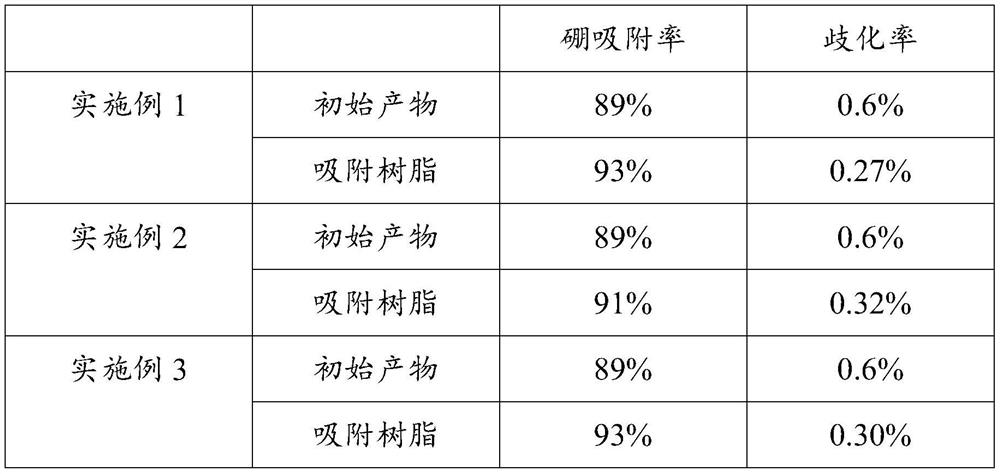

Embodiment 1

[0036] This embodiment provides a method for preparing an adsorption resin for impurity removal by chlorosilanes, which includes:

[0037] Swell chloromethylated polystyrene microspheres in toluene, then add diethylenetriamine, react at a temperature of 90°C for 4 hours to obtain a solution containing the initial product, and then filter to obtain a filtrate, alternating water and ethanol The filtrate was washed to neutral and then vacuum-dried to constant weight to obtain the initial product. Wherein, the mass ratio of chloromethylated polystyrene microspheres to diethylenetriamine is 1:12.

[0038] The initial product was mixed with 0.5wt% potassium permanganate solution, stirred and refluxed at 30°C for 2 hours to obtain an adsorption resin, then cooled, washed until neutral, and vacuum-dried at 80°C. Wherein, the ratio of potassium permanganate solution to initial product is 10mL:1g.

Embodiment 2

[0040] This embodiment provides a method for preparing an adsorption resin for impurity removal by chlorosilanes, which includes:

[0041] Swell chloromethylated polystyrene microspheres in toluene, then add triethylenetetramine, and react at a temperature of 120°C for 5 hours to obtain a solution containing the initial product, then filter to obtain a filtrate, alternately with water and ethanol The filtrate was washed to neutral and then vacuum-dried to constant weight to obtain the initial product. Wherein, the mass ratio of chloromethylated polystyrene microspheres to triethylenetetramine is 1:14.4.

[0042] The initial product was mixed with potassium permanganate solution with a concentration of 1.0wt%, stirred and refluxed at 60°C for 4 hours to obtain an adsorption resin, then cooled, washed until neutral, and vacuum-dried at 80°C. Wherein, the ratio of potassium permanganate solution to initial product is 10mL:1g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com