Catalyst for gas-phase catalytic synthesis of perfluoroiodocarbons and its preparation and application

A technology for perfluoroiodocarbon and compound, which is applied in the field of gas-phase catalytic synthesis of perfluoroiodocarbon compound catalyst and the field of preparation and application thereof, can solve the problems of theoretical upper limit of yield, high temperature, carbon deposition and the like, and is easy to achieve in preparation process conditions The effect of controlling, improving selectivity, and breaking the upper limit of existing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1—— Embodiment 11

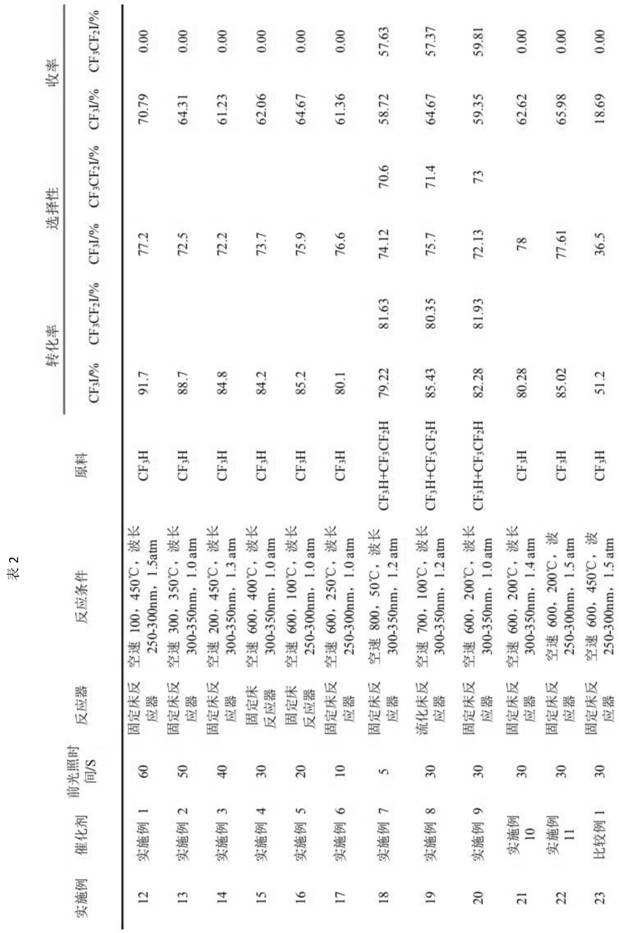

[0048] Weigh dicyandiamide or urea according to literature [Dong, F.; Wu, L.; Sun, Y.; Fu, M.; Wu, Z.; Lee, S.C., Efficient synthesis of polymeric g-C3N4layered materials as novel efficient visible C 3 N 4 , the C 3 N 4 Add it to 0.5M sulfuric acid solution, the ratio of feed to sulfuric acid solution is 1g:50mL, heat in a water bath at 80°C and stir to dissolve. Dry for 12h. Then weigh one lanthanide metal salt and one / two soluble alkali metal salts, and dissolve them to make an impregnating aqueous solution. After being fully dissolved, it is impregnated with the treated carrier in an equal volume, then left at this temperature for a certain period of time, then dried in vacuum (-0.08~-0.0MPa), and finally roasted in an inert atmosphere or a hydrogen atmosphere to obtain the obtained said catalyst. The mass ratio of each element in the catalyst was determined by ICP. The details are shown in Table 1.

Embodiment 12—— Embodiment 18

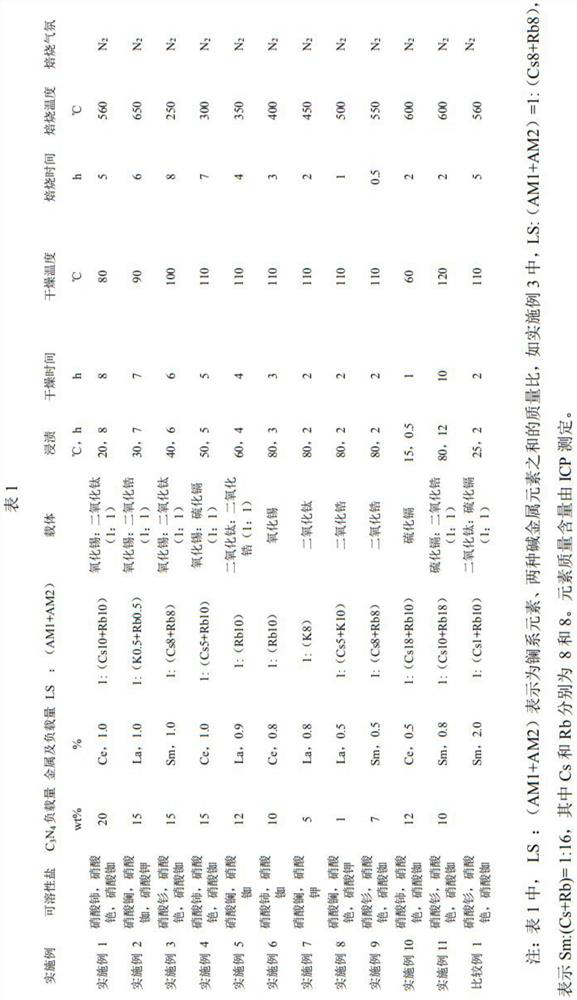

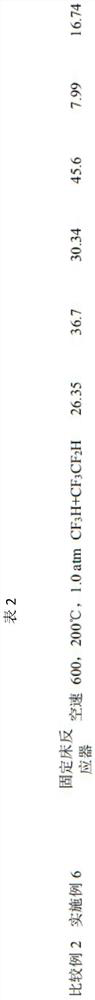

[0053] In a gas-solid reactor such as a fixed bed reactor or a fluidized bed, the perfluoroalkane compound or a mixture of several perfluoroalkane compounds and iodine vapor are simultaneously passed into the reactor according to the ratio of the amount of the substance at 1.0:1.0, and the whole The fluoroalkane compound and iodine vapor are irradiated by the photoreactor before entering the catalyst bed, and the time is not less than 5s. Set the light wavelength to 250-350nm, and the space velocity to not higher than 200-800h -1 , fully contact and react with the catalyst at 50-450°C and 1.0-1.5 atmospheric pressure. After the tail gas is absorbed by alkaline solution, dried and separated, the perfluoroiodocarbon compound is obtained. Products were analyzed by Agilent 7890A gas chromatograph. The details are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com