Antibacterial nano cuprous oxide/chitosan grafted polyacrylate emulsion as well as preparation method and application thereof

A technology of nano-cuprous oxide and polyacrylate emulsion, which is applied in the direction of antifouling/underwater coatings, coatings, paints containing biocides, etc., and can solve the problem that antibacterial polyacrylate materials are rare and have no literature and patent reports or public issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 prepares antibacterial nano cuprous oxide / chitosan grafted polyacrylate emulsion

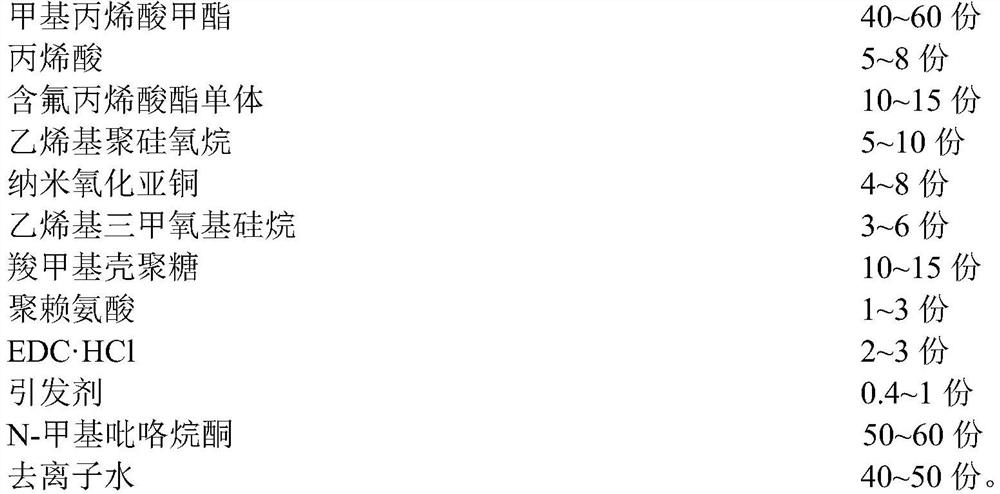

[0034] An antibacterial nano cuprous oxide / chitosan grafted polyacrylate emulsion, comprising the following raw materials in parts by mass:

[0035]

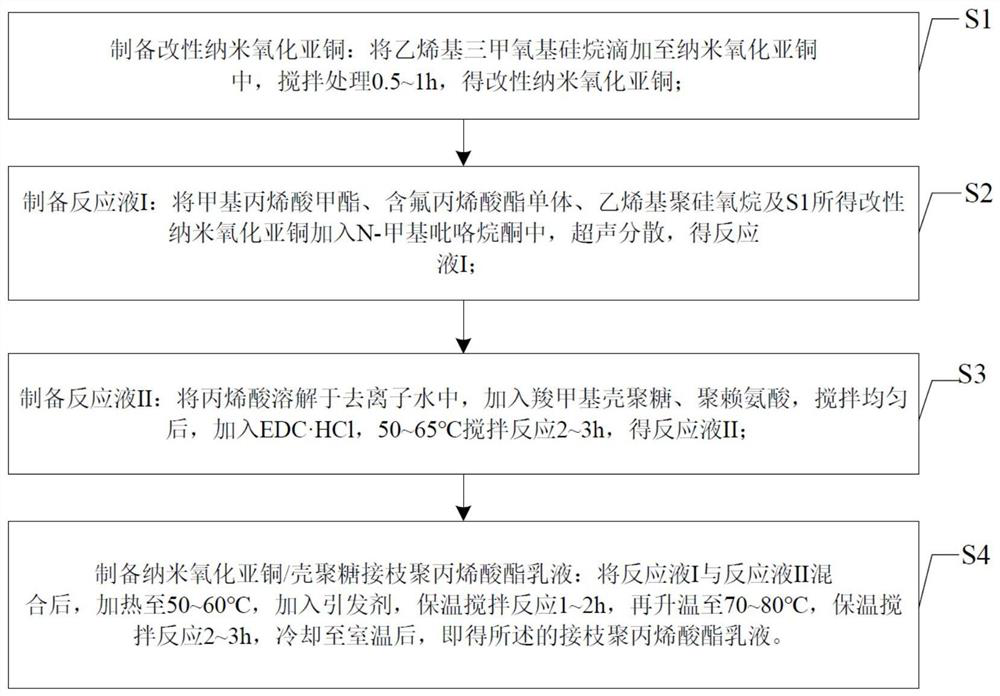

[0036] A preparation method of antibacterial nano cuprous oxide / chitosan grafted polyacrylate emulsion, comprising the following steps:

[0037] S1: Prepare modified nano-cuprous oxide: add vinyltrimethoxysilane dropwise to nano-cuprous oxide with an average particle size of 2nm, and stir for 0.5h to obtain modified nano-cuprous oxide;

[0038] S2: Preparation of reaction solution I: Add methyl methacrylate, hexafluorobutyl methacrylate, vinyl polysiloxane, and modified nano-cuprous oxide obtained in S1 into N-methylpyrrolidone, and ultrasonically disperse to obtain a reaction Liquid I;

[0039] S3: Preparation of reaction solution II: dissolving acrylic acid in deionized water, adding carboxymethyl chitosan and polylysine...

Embodiment 2

[0041] Example 2 Preparation of Antibacterial Nano Cuprous Oxide / Chitosan Grafted Polyacrylate Emulsion

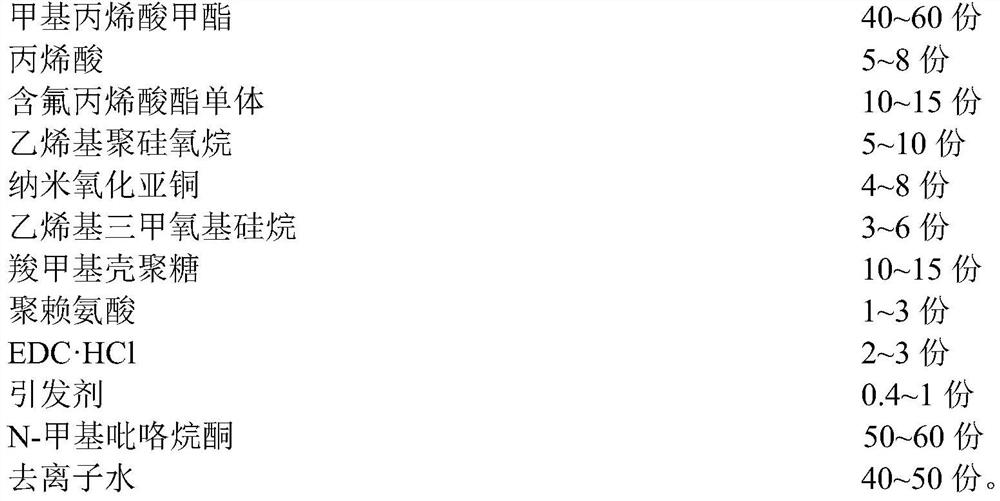

[0042] An antibacterial nano cuprous oxide / chitosan grafted polyacrylate emulsion, comprising the following raw materials in parts by mass:

[0043]

[0044] A preparation method of antibacterial nano cuprous oxide / chitosan grafted polyacrylate emulsion, comprising the following steps:

[0045] S1: Prepare modified nano-cuprous oxide: add vinyltrimethoxysilane dropwise to nano-cuprous oxide with an average particle size of 4nm, and stir for 1 hour to obtain modified nano-cuprous oxide;

[0046] S2: Preparation of reaction solution I: Add methyl methacrylate, hexafluoroisopropyl methacrylate, vinyl polysiloxane and modified nano-cuprous oxide obtained in S1 into N-methylpyrrolidone, and ultrasonically disperse to obtain Reaction solution I;

[0047] S3: Preparation of reaction solution II: Dissolve acrylic acid in deionized water, add carboxymethyl chitosan and polylysin...

Embodiment 3

[0049] Example 3 Preparation of antibacterial nano cuprous oxide / chitosan grafted polyacrylate emulsion

[0050] An antibacterial nano cuprous oxide / chitosan grafted polyacrylate emulsion, comprising the following raw materials in parts by mass:

[0051]

[0052] A preparation method of antibacterial nano cuprous oxide / chitosan grafted polyacrylate emulsion, comprising the following steps:

[0053] S1: Prepare modified nano-cuprous oxide: add vinyltrimethoxysilane dropwise to nano-cuprous oxide with an average particle size of 6 nm, and stir for 1 hour to obtain modified nano-cuprous oxide;

[0054] S2: Preparation of reaction solution I: Add methyl methacrylate, dodecafluoroheptyl acrylate, vinyl polysiloxane and modified nano-cuprous oxide obtained in S1 into N-methylpyrrolidone, and ultrasonically disperse to obtain a reaction solution I;

[0055] S3: Preparation of reaction solution II: dissolving acrylic acid in deionized water, adding carboxymethyl chitosan and poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com