Method for reducing carbon deposition of catalyst in resource utilization of HFC-23

A technology of HFC-23 and catalyst, which is applied in the field of HFC-23 resource utilization, can solve the problems of reduced product selectivity, etc., and achieve the effects of improving stability, good synergy and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

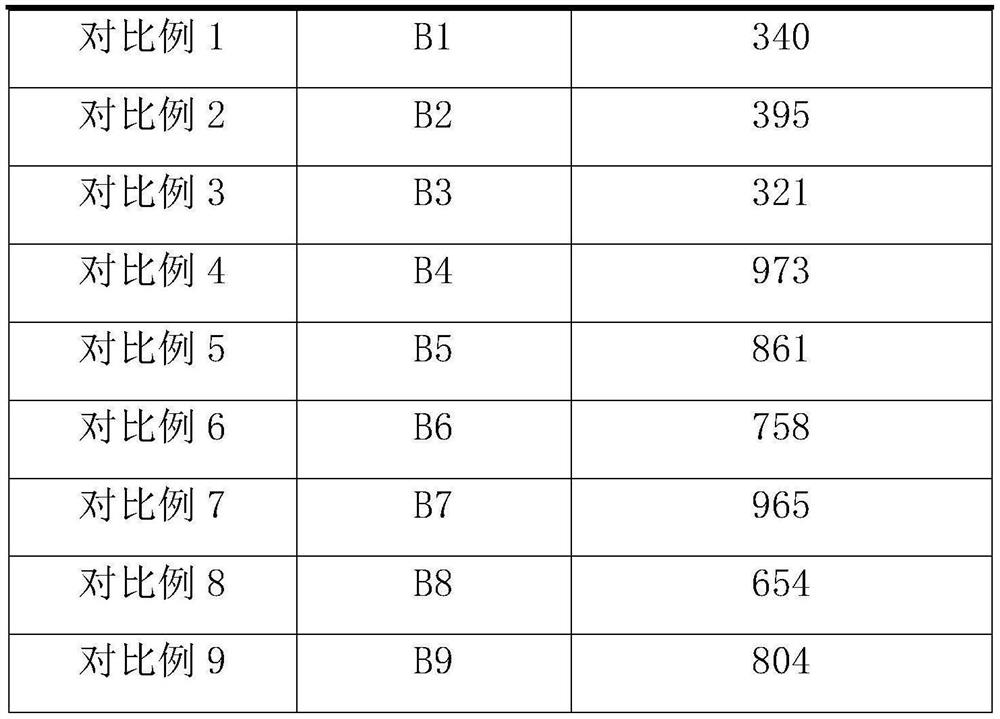

Examples

Embodiment 1

[0034] Catalyst preparation: pretreat the chromium trioxide catalyst (the main catalyst), the pretreatment process includes: 1) 250 ° C fluorination treatment for 2 hours under a mixed atmosphere of 10% hydrogen fluoride and 90% nitrogen; 2) under a hydrogen fluoride atmosphere, Treat at 300°C for 5 hours; 3) Purge nitrogen to lower the temperature. Pour the fluorinated pretreated catalyst into n-hexane, stir and disperse evenly, add the Ru nanocolloid dispersion drop by drop, control the mass content of the Ru load to 0.1%, keep stirring continuously for 4 hours, and the upper layer of the solution becomes transparent After clarification, transfer it to a rotary evaporator, evaporate to dryness at 80°C, dry in an oven at 110°C overnight, and roast in a muffle furnace at 400°C for 6 hours to obtain a shaped catalyst, which is designated as Catalyst 1.

[0035] Recycling of HFC-23: Pass trifluoromethane, chloroform and hydrogen into a reactor containing 50ml of catalyst 1 at a ra...

Embodiment 2

[0037] Catalyst preparation: pretreat the chromium trioxide catalyst (the main catalyst), the pretreatment process includes: 1) 250 ° C fluorination treatment for 2 hours under a mixed atmosphere of 10% hydrogen fluoride and 90% nitrogen; 2) under a hydrogen fluoride atmosphere, Treat at 300°C for 5 hours; 3) Purge nitrogen to lower the temperature. Pour the fluorinated pretreated catalyst into n-hexane, stir and disperse evenly, add the Pt nano-colloid dispersion drop by drop, control the Pt loading at 0.1wt%, keep stirring continuously for 4 hours, and the upper layer of the solution becomes transparent and clear After that, it was transferred into a rotary evaporator, evaporated to dryness at 80°C, dried in an oven at 110°C overnight, and calcined in a muffle furnace at 400°C for 6 hours to obtain a shaped catalyst, which was designated as Catalyst 2.

[0038] Recycling of HFC-23: Pass trifluoromethane, chloroform and hydrogen into a reactor containing 50ml of catalyst 2 at...

Embodiment 3

[0040] Catalyst preparation: pretreat the chromium trioxide catalyst (the main catalyst), the pretreatment process includes: 1) 250 ° C fluorination treatment for 2 hours under a mixed atmosphere of 10% hydrogen fluoride and 90% nitrogen; 2) under a hydrogen fluoride atmosphere, Treat at 300°C for 5 hours; 3) Purge nitrogen to lower the temperature. Pour the fluorinated pretreated catalyst into n-hexane, stir and disperse evenly, add the Pd nano-colloid dispersion drop by drop, control the mass loading of Pd at 0.1%, keep stirring continuously for 4 hours, and the upper layer of the solution becomes transparent and clear After that, it was transferred into a rotary evaporator, evaporated to dryness at 80°C, dried in an oven at 110°C overnight, and calcined in a muffle furnace at 400°C for 6 hours to obtain a shaped catalyst, which was designated as Catalyst 3.

[0041] Recycling of HFC-23: Pass trifluoromethane, chloroform and hydrogen into a reactor containing 50ml of catalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com