Method for preparing ultrahigh-purity ethyl methyl carbonate through continuous rectification device

An ultra-high-purity technology of ethyl methyl carbonate, applied in the field of ethyl methyl carbonate production, can solve the problems of ethyl methyl carbonate disproportionation reaction content, low yield, long operation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

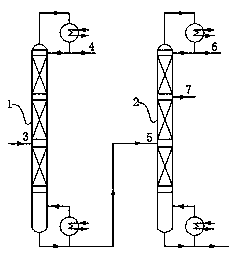

[0019] Such as figure 1 As shown, the present invention discloses a method for producing ultra-high-purity ethyl methyl carbonate by a continuous rectification device, comprising: rectification tower one 1, rectification tower two 2, characterized in that: said rectification tower one Add ethyl methyl carbonate through the feed inlet-3 provided on 1, the discharge outlet-4 that the tower top of described rectification tower-1 is provided with takes off gas phase light component, the tower in the bottom of described rectification tower-1 inner bottom The still material is transported to the feed inlet 25 by the conveying pump and enters the rectification tower 2 2, and the discharge port 2 6 provided on the top of the rectification tower 2 sloughs out gas phase light components, and the upper part of the rectification tower 2 2 The set outlet three 7 extracts high-purity ethyl methyl carbonate product, and the heavy component of the tower still material at the inner bottom of t...

Embodiment 2

[0027] Such as figure 1 As shown, the present invention discloses a method for producing ultra-high-purity ethyl methyl carbonate by a continuous rectification device, comprising: rectification tower one 1, rectification tower two 2, characterized in that: said rectification tower one Add ethyl methyl carbonate through the feed inlet-3 provided on 1, the discharge outlet-4 that the tower top of described rectification tower-1 is provided with takes off gas phase light component, the tower in the bottom of described rectification tower-1 inner bottom The still material is transported to the feed inlet 25 by the conveying pump and enters the rectification tower 2 2, and the discharge port 2 6 provided on the top of the rectification tower 2 sloughs out gas phase light components, and the upper part of the rectification tower 2 2 The set outlet three 7 extracts high-purity ethyl methyl carbonate product, and the heavy component of the tower still material at the inner bottom of t...

Embodiment 3

[0035] Such as figure 1As shown, the present invention discloses a method for producing ultra-high-purity ethyl methyl carbonate by a continuous rectification device, comprising: rectification tower one 1, rectification tower two 2, characterized in that: said rectification tower one Add ethyl methyl carbonate through the feed inlet-3 provided on 1, the discharge outlet-4 that the tower top of described rectification tower-1 is provided with takes off gas phase light component, the tower in the bottom of described rectification tower-1 inner bottom The still material is transported to the feed inlet 25 by the conveying pump and enters the rectification tower 2 2, and the discharge port 2 6 provided on the top of the rectification tower 2 sloughs out gas phase light components, and the upper part of the rectification tower 2 2 The set outlet three 7 extracts high-purity ethyl methyl carbonate product, and the heavy component of the tower still material at the inner bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com