A kind of rare earth tungsten-molybdenum alloy used for electrode and preparation method thereof

A rare earth tungsten and molybdenum alloy technology, applied in the field of alloy research, can solve the problems of poor electrical conductivity of tungsten and molybdenum alloys, insufficient alloy sintering, and low recrystallization temperature, so as to improve processing performance, strengthen grain boundary bonding force, and improve resistance The effect of high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

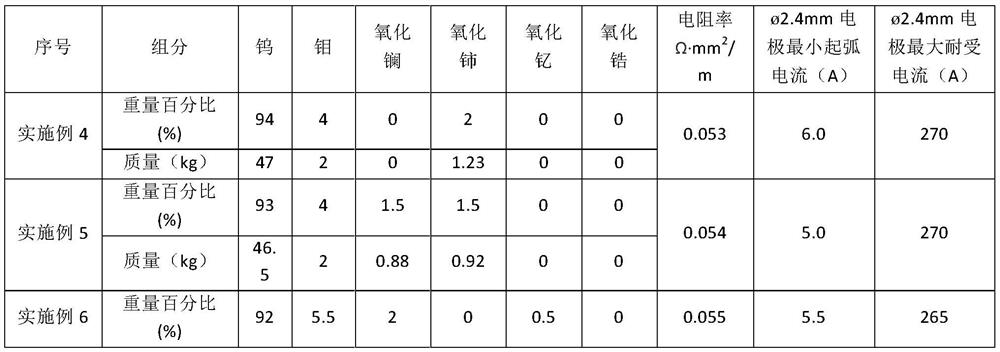

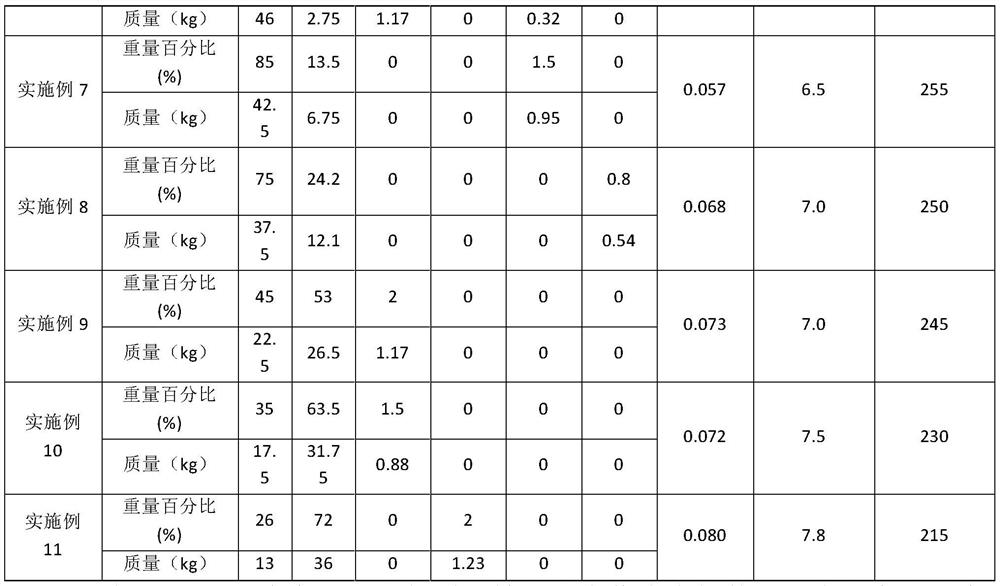

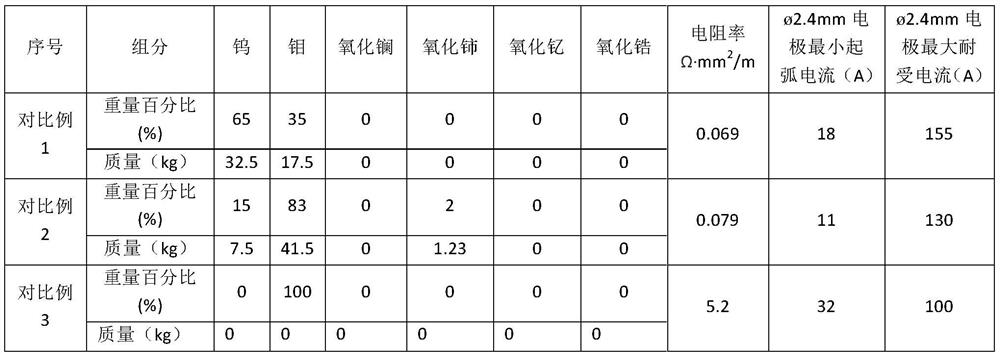

Examples

Embodiment 1

[0047] The preparation of rare earth tungsten-molybdenum alloy includes the following steps:

[0048] 1) Powder mixing: According to the weight ratio of 64% tungsten, 33.5% molybdenum and 2.5% rare earth, put 32kg of tungsten powder, 16.75kg of molybdenum powder, 0.88kg of lanthanum oxide, 0.32kg of yttrium oxide and 0.34kg of zirconia into the In the "V" type mixer, mix for 0.5h to obtain synthetic powder;

[0049] 2) Powder filling: Take 920 grams of synthetic powder and put it into the rubber sleeve on the vibration platform, vibrate for 0.5h, vibrate until it is uniform and dense, and then seal it with a plug;

[0050] 3) Forming: Place the sealed rubber sleeve on the rubber sleeve frame, then put the rubber sleeve frame into the barrel of the cold isostatic press, increase the pressure from 0MPa to 145-165MPa within 5-6min, The duration of the pressure holding process under 165MPa is 1-5min, and then the pressure relief is completed within 3-5min. After the cool pressing...

Embodiment 2

[0057] The preparation of rare earth tungsten-molybdenum alloy includes the following steps:

[0058] 1) Powder mixing: According to the weight ratio of 30% tungsten, 68.5% molybdenum and 1.5% rare earth, put 15kg tungsten powder, 34.25kg molybdenum powder, and 0.92kg cerium oxide into the "V" type mixer, mix for 0.5h, get synthetic powder;

[0059] 2) Powder filling: Take 1000 grams of synthetic powder and put it into the rubber sleeve on the vibration platform, vibrate for 0.5h, vibrate until it is uniform and compact, and then seal it with a plug;

[0060] 3) Forming: Place the sealed rubber sleeve on the rubber sleeve frame, then put the rubber sleeve frame into the cylinder of the cold isostatic press, increase the pressure from 0MPa to 155MPa within 5min, and maintain the pressure at 155MPa The duration is 3 minutes, and then the pressure relief is completed within 4 minutes. After the cool pressing is completed, the material rack is taken out, and the compact is obtain...

Embodiment 3

[0067] The preparation of rare earth tungsten-molybdenum alloy includes the following steps:

[0068] 1) Powder mixing: according to the weight ratio of 90% tungsten, 8% molybdenum and 2% rare earth, put 45kg tungsten powder, 4kg molybdenum powder, and 1.23kg cerium oxide into a "V" type mixer, and mix for 0.5h to obtain synthetic powder;

[0069] 2) Powder filling: Take 1350 grams of synthetic powder and put it into the rubber sleeve on the vibration platform, vibrate for 0.5h, vibrate until it is uniform and dense, and then seal it with a plug;

[0070] 3) Forming: Place the sealed rubber sleeve on the rubber sleeve frame, then put the rubber sleeve frame into the cylinder of the cold isostatic press, increase the pressure from 0MPa to 160MPa within 5min, and maintain the pressure at 160MPa The duration is 3 minutes, and then the pressure relief is completed within 4 minutes. After the cool pressing is completed, the material rack is taken out, and the compact is obtained b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com