Special steel drainage agent and preparation method thereof

A kind of technology of drainage agent and variety, applied in foundry equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of unstable self-opening rate, molten steel pollution, high cost, and achieve high refractoriness, pollution removal, and resistance to molten steel. The effect of erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

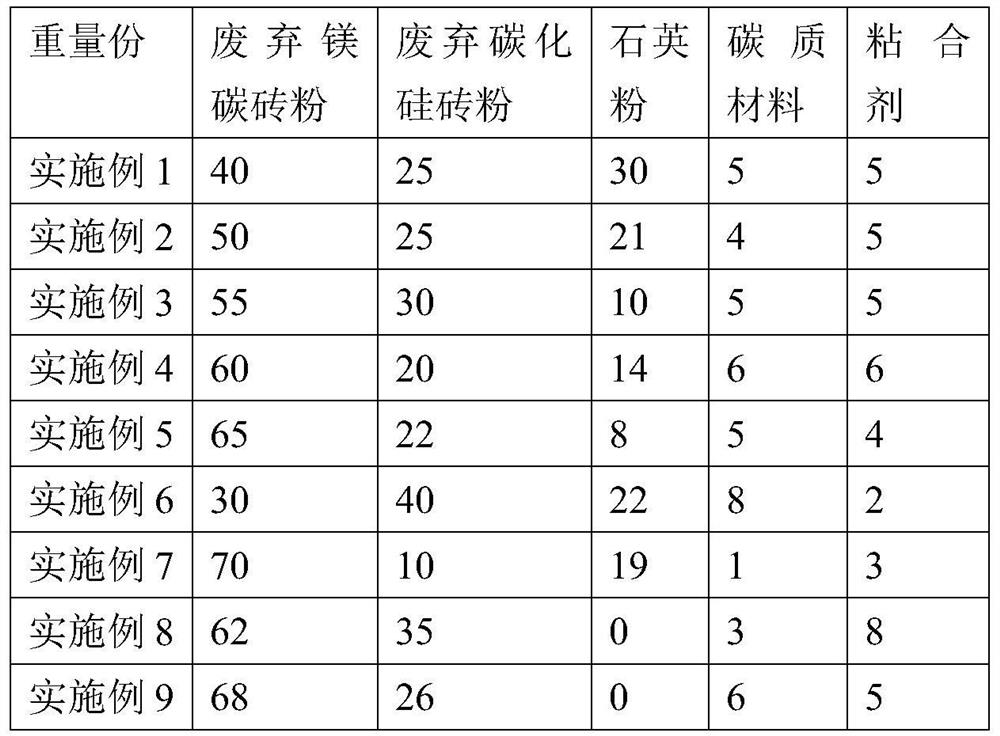

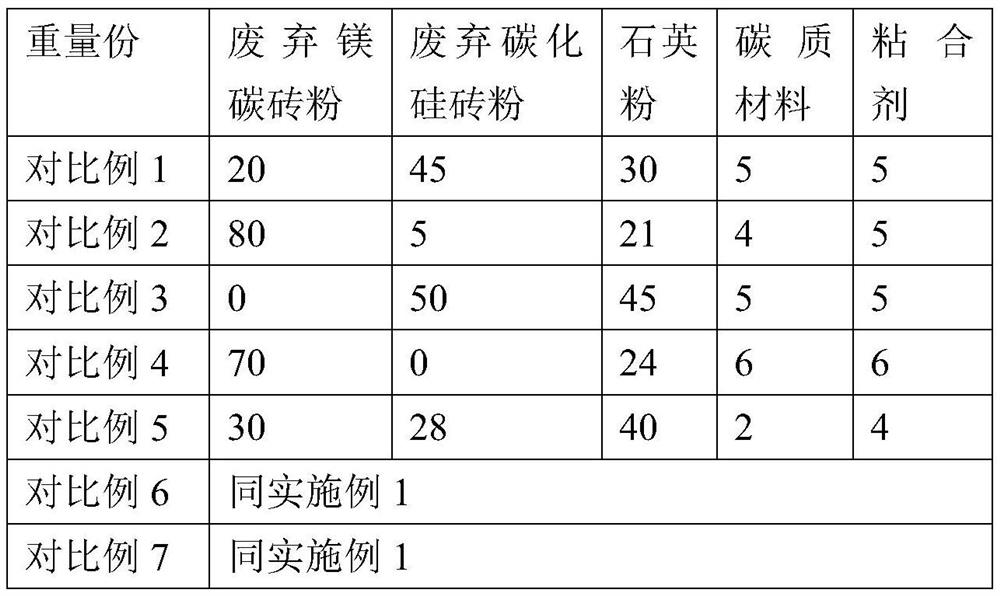

Embodiment 1

[0039] Take the waste magnesia carbon brick powder and waste silicon carbide brick powder, quartz powder, carbonaceous material and adhesive through grinding and iron removal treatment according to Table 1; after accurate measurement, the waste magnesia carbon brick powder and waste silicon carbide brick Add the powder into the granulation tray, add the binder and rotate and stir for 15 minutes, then add the carbonaceous material, continue to rotate and roll for 5 minutes, and transport it to the sifting device, sieve the material and send it to the storage tank. 0.3-1.5mm > 96%, of which 0.3-0.6mm > 40%, 0.6-1.0mm > 40%, 1.0-1.2mm > 15%; then transported into the drying system for drying, the drying temperature is 650 ° C, The exhaust air temperature is 150°C, the drying flow rate is controlled at 3 tons per hour, and the drum speed is 30r / min to ensure that the moisture content is within 0.1%. After being cooled by the cooling drum, it is packaged and put into storage.

Embodiment 2

[0041] Take the waste magnesia carbon brick powder and waste silicon carbide brick powder, quartz powder, carbonaceous material and adhesive through grinding and iron removal treatment according to Table 1; after accurate measurement, the waste magnesia carbon brick powder and waste silicon carbide brick Add the powder into the granulation tray, add the binder and rotate and stir for 10 minutes, then add the carbonaceous material, continue to rotate and roll for 5 minutes, and transport it to the sifting device, sieve the material and send it to the storage tank. 0.3-1.5mm > 96%, of which 0.3-0.6mm > 40%, 0.6-1.0mm > 40%, 1.0-1.2mm > 15%; then transported into the drying system for drying, the drying temperature is 630 ° C, The exhaust air temperature is 120°C, the drying flow rate is controlled at 2.5 tons per hour, and the drum speed is 25r / min to ensure that the moisture content is within 0.1%. After being cooled by the cooling drum, it is packaged and put into storage.

Embodiment 3

[0043] Take the waste magnesia carbon brick powder and waste silicon carbide brick powder, quartz powder, carbonaceous material and adhesive through grinding and iron removal treatment according to Table 1; after accurate measurement, the waste magnesia carbon brick powder and waste silicon carbide brick Put the powder into the granulation tray, add the binder and rotate and stir for 12 minutes, then add the carbonaceous material, continue to rotate and roll for 5 minutes, and transport it to the sifting device, sieve the material and send it to the storage tank. 0.3-1.5mm > 96%, of which 0.3-0.6mm > 40%, 0.6-1.0mm > 40%, 1.0-1.2mm > 15%; then transported into the drying system for drying, the drying temperature is 670 ° C, The exhaust air temperature is 170°C, the drying flow rate is controlled at 3 tons per hour, and the drum speed is 30r / min to ensure that the moisture content is within 0.1%. After being cooled by the cooling drum, it is packaged and put into storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com