Preparation method of NCM811-type high-nickel ternary positive electrode material

A cathode material, high nickel technology, applied in the field of nickel-cobalt-manganese ternary cathode material production, can solve the problems of increasing Li+ diffusion kinetic resistance, low tap density, poor high temperature performance, etc., to improve cycle performance and charge-discharge Capacity, suppression of phase transition, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] a. Mixing: using ternary precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 Lithium hydroxide is used as a raw material, and the total molar ratio of lithium and nickel-cobalt-manganese metal is 1.05:1 during batching, mixed and ground, so that lithium, nickel-cobalt-manganese are evenly mixed;

[0027] b. Primary sintering: Sinter the uniformly mixed above-mentioned materials in stages using a tube furnace with pure oxygen. The first stage of sintering is at a temperature of 400 °C for 4 h; the second stage of sintering is at a temperature of 600 °C for 3 h; Three-stage sintering, sintering temperature 750 ℃, sintering 10h, after sintering is completed, lower to room temperature;

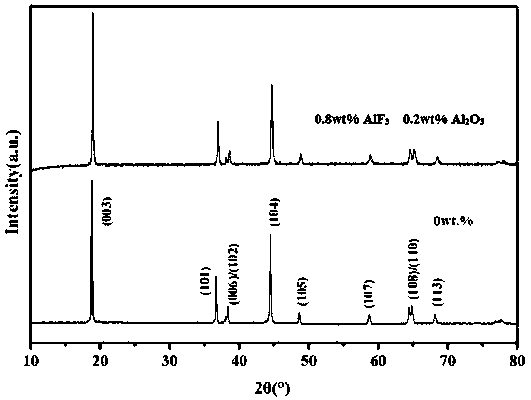

[0028] c. Coating: The material obtained by primary sintering is crushed, sieved, and mixed with nano-Al 2 o 3 and AlF 3 As a coating agent, doped with nano-Al 2 o 3 and AlF 3 The usage of the corresponding precursor is 0.2% and 0.8%, respectively, and the mechanical fusion machine with a rotati...

Embodiment 2

[0033] a. Mixing: using ternary precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 Lithium hydroxide is used as a raw material, and the total molar ratio of lithium and nickel-cobalt-manganese metal is 1.01:1 during batching, mixed and ground, so that lithium, nickel-cobalt-manganese are evenly mixed;

[0034] b. Primary sintering: The uniformly mixed raw meal is sintered in stages using a tube furnace with pure oxygen. The first stage is sintered at 500°C for 6 hours; the second stage is sintered at 700°C for 4 hours; the third stage is sintered Stage sintering, the sintering temperature is 870 ° C for 15 h; after the sintering is completed, the temperature is lowered to room temperature 25 ° C, and finally the lithium-ion battery cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 ;

[0035] c. Coating: The material obtained by primary sintering is crushed, sieved, and mixed with nano-Al 2 o 3 and LiF as a coating agent, doped with nano-Al 2 o 3 The amount of the precursor correspondi...

Embodiment 3

[0040] a. Mixing: using ternary precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 And Lithium Retard as raw material, lithium and nickel-cobalt-manganese metal total molar ratio 1.09:1 during batching, mixing and grinding, lithium, nickel-cobalt-manganese are evenly mixed;

[0041] b. Primary sintering: The uniformly mixed raw meal was sintered in stages using a tube furnace with pure oxygen. The first stage of sintering was held at 500 °C for 6 h; the second stage of sintering was held at 700 °C for 4 h; Three-stage sintering, the sintering temperature is 800 ° C for 15 h; after the sintering is completed, the temperature is lowered to room temperature 25 ° C, and finally the lithium-ion battery cathode material LiNi is obtained. 0.8 co 0.1 mn 0.1 o 2 ;

[0042] c. Coating: The material obtained by primary sintering is crushed, sieved, and mixed with nano-Al 2 o 3 and LiF as a coating agent, doped with nano-Al 2 o 3 The amount of the precursor corresponding to LiF is 0.3% and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com