Preparation method of modified watermelon peel adsorbent

A technology of watermelon rind and adsorbent, applied in the field of preparation of modified watermelon rind adsorbent, to achieve the effects of easy availability of raw materials, low preparation cost, and great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

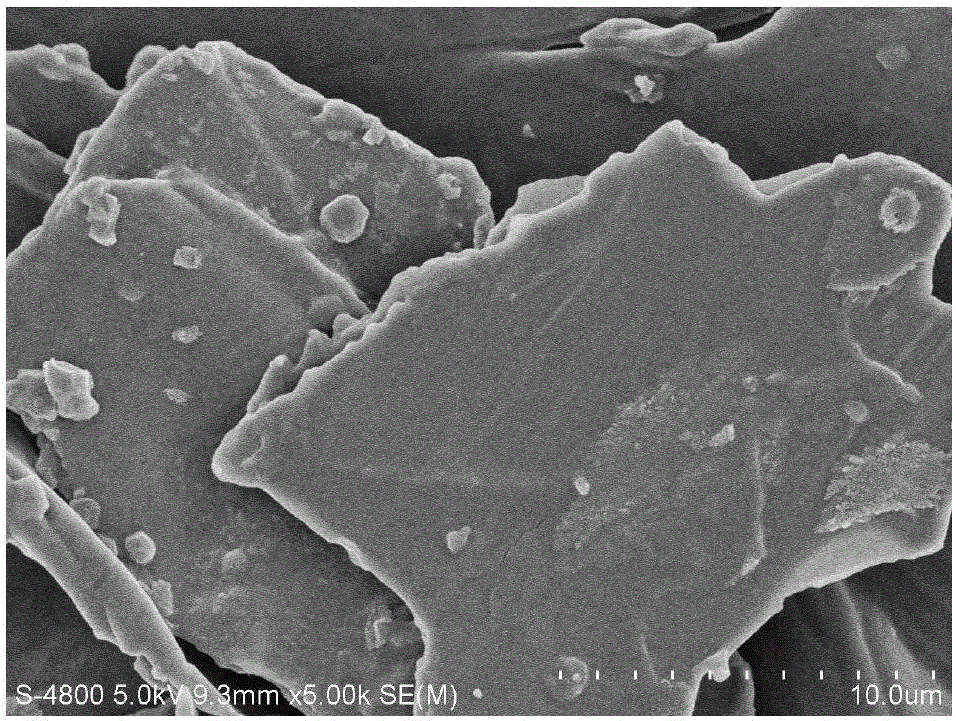

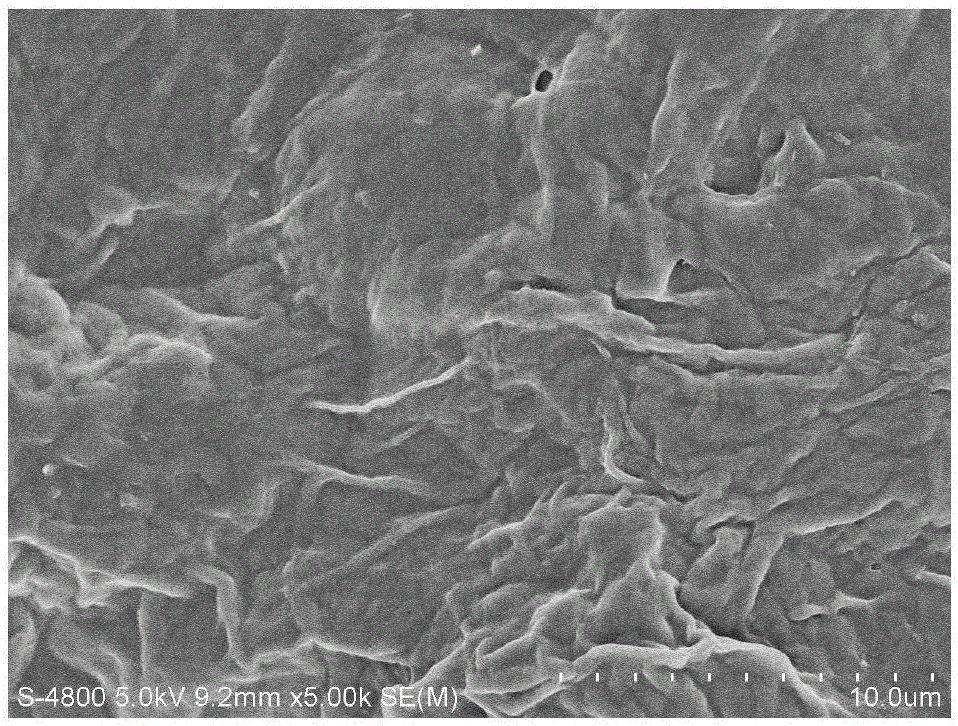

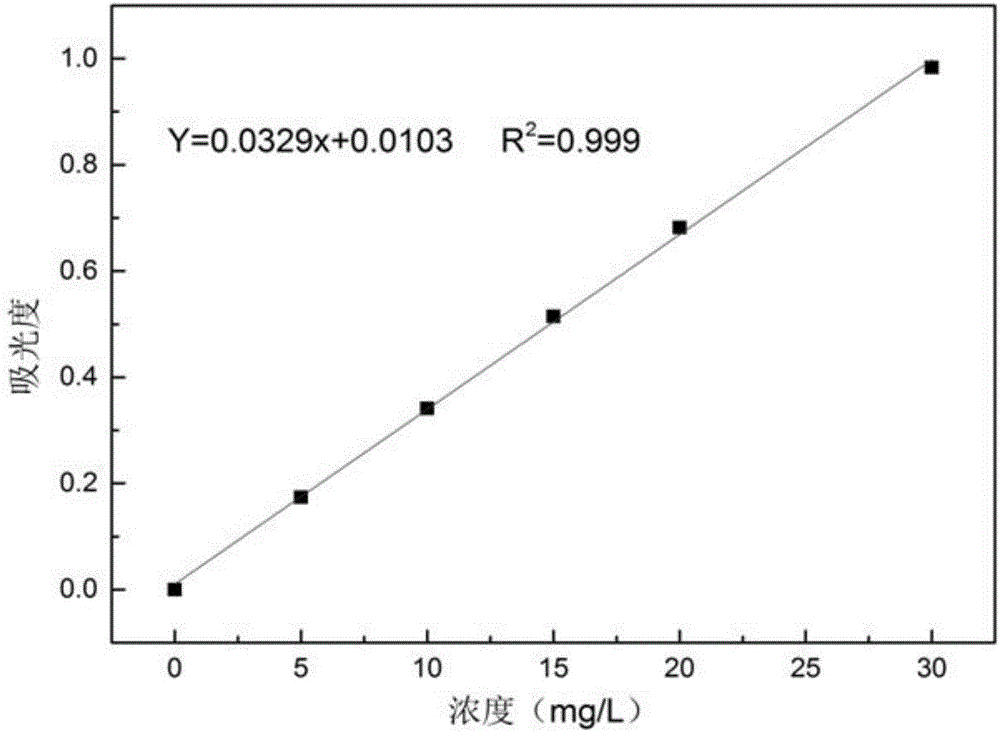

Image

Examples

Embodiment 1

[0028] The preparation method of modified watermelon rind adsorbent of the present invention comprises the steps:

[0029] Step 1, prepare watermelon rind powder: remove the red pulp part on the recovered watermelon rind, cut the watermelon rind that has removed the red pulp part into small pieces with an area of 5 square centimeters and place it in deionized water for 1 hour, and after cooling, The watermelon rind pieces are soaked in an ethanol solution with a volume fraction of 50% (v / v) for 5 hours, cleaned with deionized water after soaking, dried at 80° C., and then pulverized through an 80-mesh sieve to obtain watermelon rind powder; ethanol Able to sterilize and prevent pesticides and other substances from affecting materials;

[0030] Step 2, soak 6g of watermelon rind powder in 300mL of 8% phosphoric acid solution by mass for 10 hours; wash the soaked watermelon rind powder with deionized water until the pH of the effluent after cleaning is neutral; phosphoric acid...

Embodiment 2

[0035] The preparation method of modified watermelon rind adsorbent of the present invention comprises the steps:

[0036] Step 1, prepare watermelon rind powder: remove the red pulp part on the recovered watermelon rind, cut the watermelon rind that has removed the red pulp part into small pieces with an area of 5 square centimeters and place it in deionized water for 2 hours, and after cooling, The watermelon rind pieces were soaked in an ethanol solution with a volume fraction of 60% (v / v) for 3 hours, washed with deionized water after soaking, dried at 105° C., and then pulverized through an 80-mesh sieve to obtain watermelon rind powder;

[0037] Step 2, soak 6g of watermelon rind powder in 300mL of 5% phosphoric acid solution by mass for 12 hours; wash the soaked watermelon rind powder with deionized water until the pH of the effluent after cleaning is neutral;

[0038] Step 3, add 300mL of deionized water to 3g of washed watermelon rind powder, and add 8mL of sodium h...

Embodiment 3

[0042] The preparation method of modified watermelon rind adsorbent of the present invention comprises the steps:

[0043] Step 1, prepare watermelon rind powder: remove the red pulp part on the recovered watermelon rind, cut the watermelon rind that has removed the red pulp part into small pieces with an area of 5 square centimeters and place it in deionized water for 3 hours, and after cooling, Watermelon rind pieces were soaked in an ethanol solution with a volume fraction of 40% (v / v) for 4 hours, washed with deionized water after soaking, dried at 105° C., and then pulverized through an 80-mesh sieve to obtain watermelon rind powder;

[0044] Step 2, soak 6g of watermelon rind powder in 300mL of 10% phosphoric acid solution by mass for 15 hours; wash the soaked watermelon rind powder with deionized water until the pH of the effluent after cleaning is neutral;

[0045] Step 3, add 300mL of deionized water to 3g of washed watermelon rind powder, and add 5mL of sodium hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com