Coating composition of nano cellulose, its uses and a method for its manufacture

一种纳米纤维素、组合物的技术,应用在水性涂料组合物领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1a

[0082] Example 1a. Preparation of Microfibrillated Cellulose (Nanocellulose)

[0083] The cellulose selected for the production of microfibrillated cellulose was obtained from Bleached long-fiber kraft kraft pulp (Kraft pulp) (fully bleached kraft pulp mainly based on spruce that is completely chlorine-free). Kraft pulp was mechanically treated in a Claflin cone homogenizer using a specific energy consumption of 2000 kWh / ton combined with homogenization. Homogenization was done using a high pressure homogenizer (model 12.56VH, APV, Rannie LAB) at a consistency of 0.5 to 1% with 5 passes and a pressure of 1000 bar [8].

Embodiment 1b

[0084] Example 1b. Preparation of Microfibrillated Cellulose (Nanocellulose)

[0085] The cellulose selected for the production of microfibrillated cellulose was obtained from Bleached long-fiber kraft kraft pulp (fully bleached kraft pulp mainly based on spruce that is completely chlorine-free). Kraft pulp was mechanically treated in a Claflin cone homogenizer using a specific energy consumption of 2000 kWh / ton combined with homogenization. Homogenization was done using a high pressure homogenizer (model 12.56VH, APV, Rannie LAB) at a consistency of 0.5 to 1% with 5 passes and a pressure of 1000 bar [8].

[0086] Nanocellulose concentrates (1% to 4%) are obtained by centrifugation or evaporation from 0.5% to 1.0% aqueous dispersions of nanocellulose produced by the homogenization process. Centrifugation was performed in a Heraeus 400R (Thermo Fisher Scientific Inc., Waltham, MA, USA) at 2500 rpm and 22°C during 60 minutes. This treatment is repeated until the desired con...

Embodiment 2

[0087] Example 2. Preparation and testing of compositions according to the invention

[0088] Table 1: Surfactants selected for testing

[0089]

[0090] According to principles known to those skilled in the art, cationic surfactants according to Table 2 were added to 1% to 4% of the aqueous dispersion of nanocellulose (Example 1b). The composition was stirred for 10 minutes after adding the surfactant and the pH of the composition was adjusted to neutral pH (pH 6 to 7) by adding HCl and / or NaOH. The compositions were evaporated to different dry matter contents (2.24% to 5.55%) in an oven at 75°C. A summary about sample preparation and its rheological testing is shown in Table 2.

[0091] Table 2: Summary table of tests performed on different solutions

[0092]

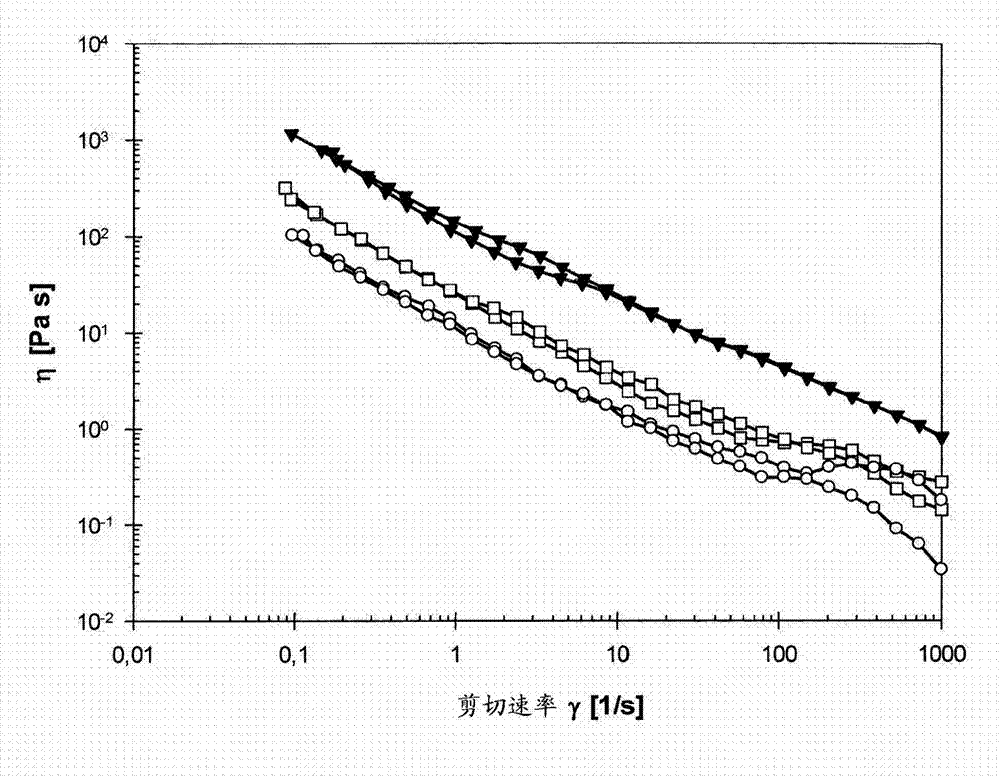

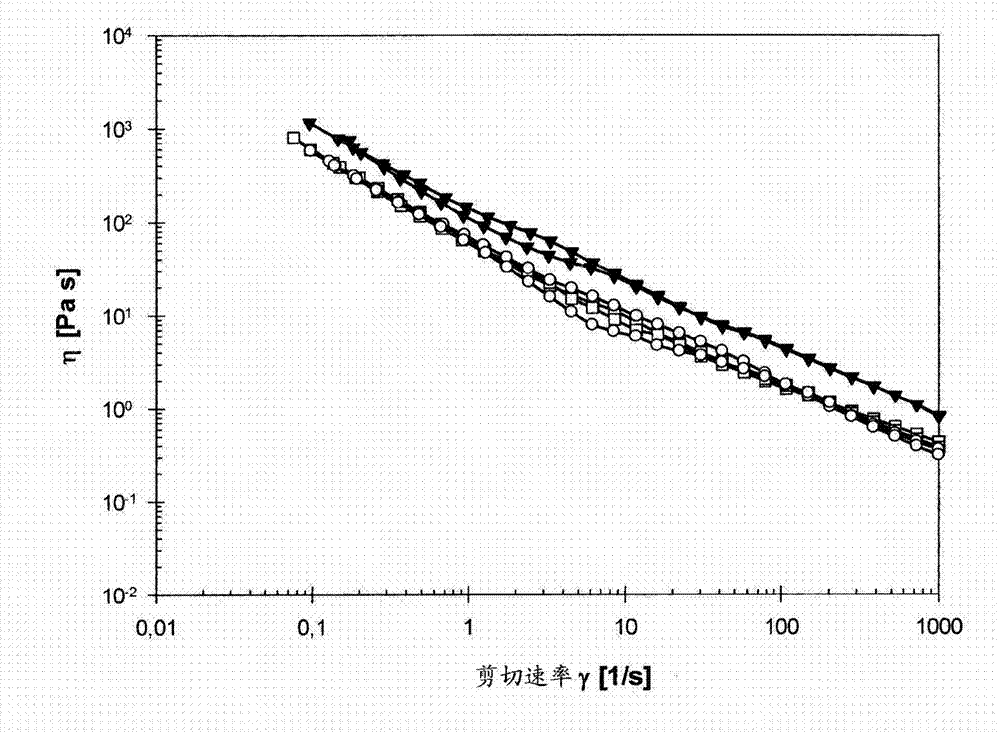

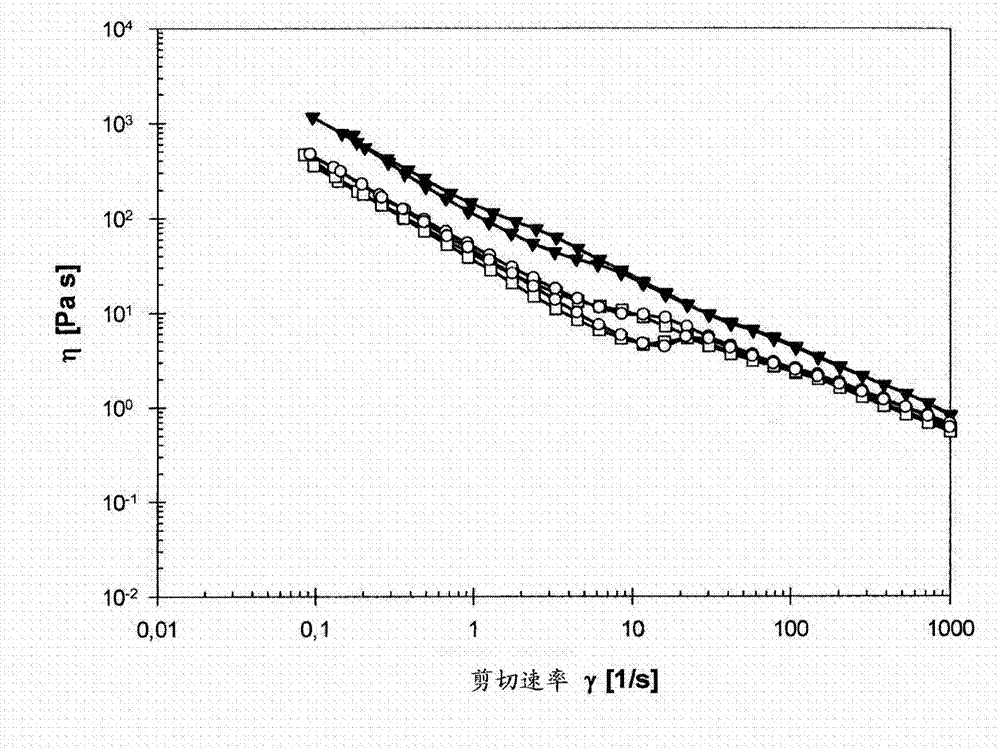

[0093] Rheological measurement

[0094] The low-shear and oscillatory rheological properties of the nanocellulose dispersions were measured on a Physica MCR 301 (Anton Paar GmbH, Graz, Austria) rotationa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| base weight | aaaaa | aaaaa |

| coating mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com