Graphene-based polyurethane composite preparation method

An alkenyl polyurethane and composite material technology, applied in the field of composite materials, can solve the problems of single function, unable to meet application requirements, low strength, etc., and achieve the effects of excellent comprehensive performance, good application value, and improved low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of graphene-based polyurethane composite material, its step is as follows:

[0022] Step 1, prepare graphene oxide according to the Hummers method, ultrasonically disperse graphene oxide in a mixed solution of ethylene glycol and water with a volume ratio of 1:2, make a graphene oxide solution with a concentration of 2 mg / ml, and adjust the pH value of the solution To 10, add polyvinyl alcohol, molybdenum disulfide, vinyl tri-n-butoxysilane, octadecyltrimethylammonium bromide and N-methylpyrrolidone solution, stir evenly, then add isocyanate and vitamin C at 85 ℃ for 8 hours, alternately washed with deionized water and absolute ethanol until neutral, and freeze-dried to obtain modified graphene; the graphene oxide, polyvinyl alcohol, molybdenum disulfide, vinyl tri-n-butoxy The molar ratio of silane, octadecyltrimethylammonium bromide, N-methylpyrrolidone, isocyanate and vitamin C is 1:0.2:1.3:0.1:0.6:15:0.4:0.7;

[0023] Step 2, diphenylmethane ...

Embodiment 2

[0026] The preparation method of graphene-based polyurethane composite material, its step is as follows:

[0027] Step 1, prepare graphene oxide according to the Hummers method, ultrasonically disperse graphene oxide in a mixed solution of ethylene glycol and water with a volume ratio of 3:5, and prepare a graphene oxide solution with a concentration of 20mg / ml, and adjust the pH value of the solution For 13, add polyvinyl alcohol, molybdenum disulfide, vinyl tri-n-butoxysilane, octadecyltrimethylammonium bromide and N-methylpyrrolidone solution, stir evenly, then add isocyanate and vitamin C at 110 react at ℃ for 20 hours, alternately wash with deionized water and absolute ethanol until neutral, and freeze-dry to obtain modified graphene; the graphene oxide, polyvinyl alcohol, molybdenum disulfide, vinyl tri-n-butoxy The molar ratio of silane, octadecyltrimethylammonium bromide, N-methylpyrrolidone, isocyanate and vitamin C is 4:0.5:1.8:0.8:1.2:22:1.3:1.6;

[0028] Step 2, d...

Embodiment 3

[0031] The preparation method of graphene-based polyurethane composite material, its step is as follows:

[0032] Step 1, prepare graphene oxide according to the Hummers method, ultrasonically disperse graphene oxide in a mixed solution of ethylene glycol and water with a volume ratio of 2:3.5, and prepare a graphene oxide solution with a concentration of 11mg / ml, adjust the pH value of the solution For 12, add polyvinyl alcohol, molybdenum disulfide, vinyl tri-n-butoxysilane, octadecyltrimethylammonium bromide and N-methylpyrrolidone solution, stir evenly, then add isocyanate and vitamin C at 98 react at ℃ for 14 hours, alternately wash with deionized water and absolute ethanol until neutral, and freeze-dry to obtain modified graphene; the graphene oxide, polyvinyl alcohol, molybdenum disulfide, vinyl tri-n-butoxy The molar ratio of silane, octadecyltrimethylammonium bromide, N-methylpyrrolidone, isocyanate and vitamin C is 2.5:0.3:1.5:0.5:0.9:18:0.8:1.2;

[0033]Step 2, dip...

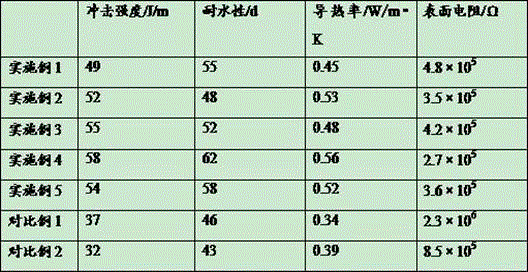

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Water resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com