Phase change heat storage coating, and preparation method and application thereof

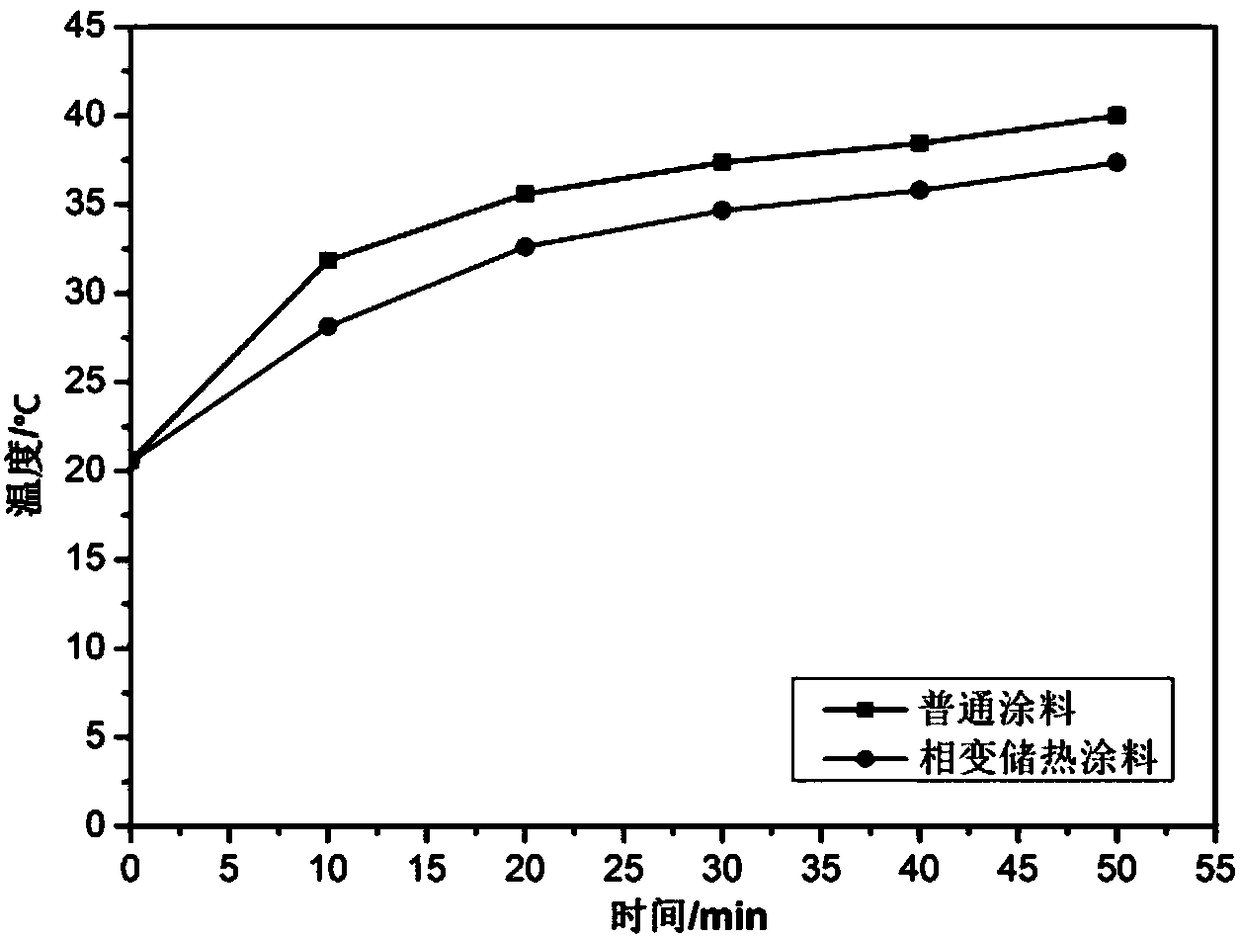

A technology of phase change heat storage and coating, applied in the direction of heat exchange materials, epoxy resin coatings, chemical instruments and methods, etc., can solve problems such as roughness, no phase change coating preparation research, phase change heat storage cement board thickness, etc. , to achieve the effect of improving thermal conductivity, excellent temperature regulation performance, and reducing indoor temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of phase change thermal storage paint, its preparation method comprises the following steps:

[0041] (1) 25g of lauryl alcohol, 1.5g of styrene maleic anhydride sodium salt and 50g of water were stirred at a high speed at 40°C, and the pH was adjusted to 3-4 with citric acid to obtain a core material emulsion;

[0042] (2) Add 11g of melamine, 21.5g of formaldehyde and 10g of graphene oxide aqueous dispersion into a round bottom flask, heat and stir until the liquid becomes clear, adjust the pH of the liquid to 8-9 with MA-95, and continue at 70°C React for 3h to obtain a solution containing the wall material prepolymer;

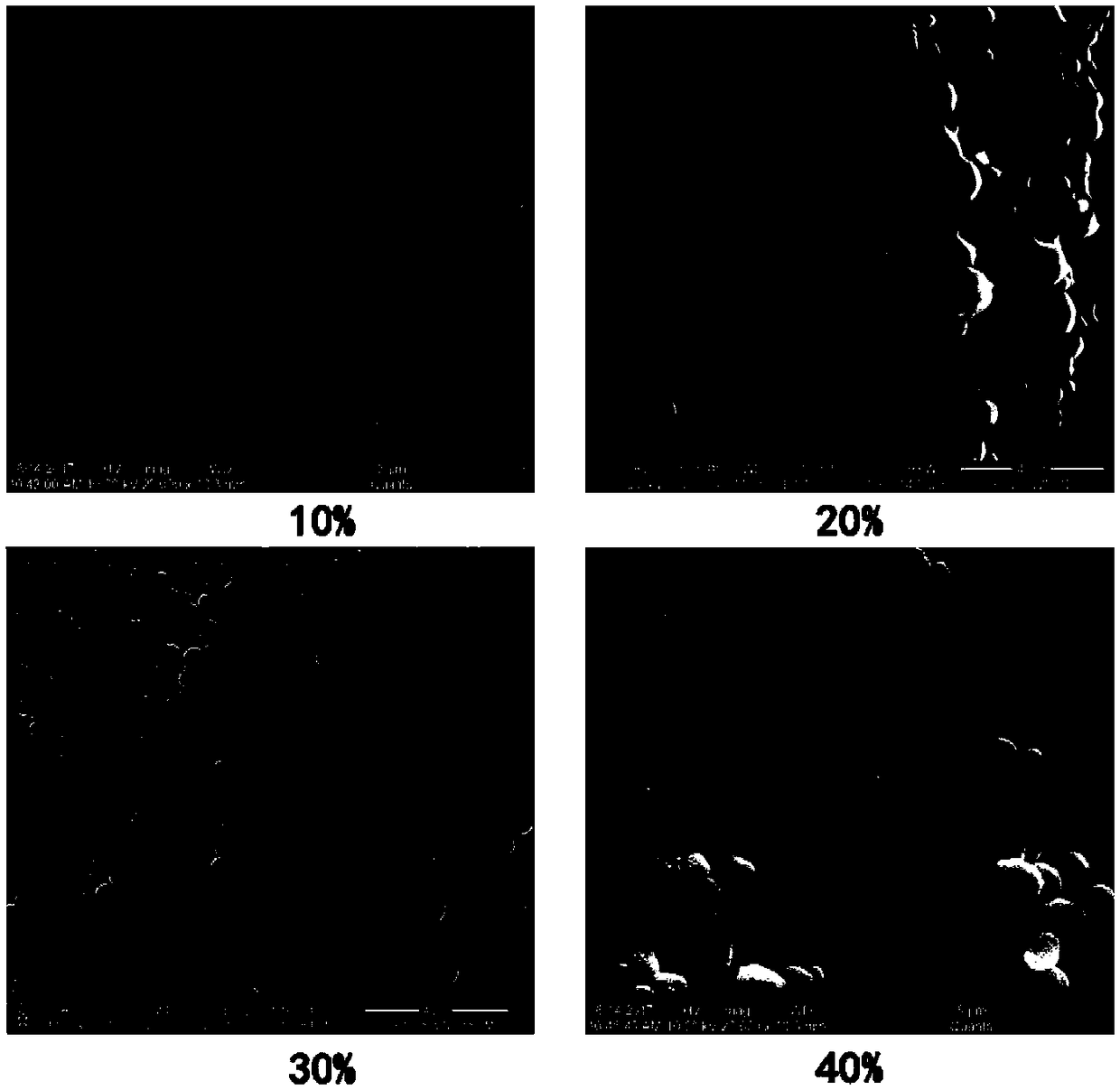

[0043] (3) Slowly add the solution containing the wall material prepolymer in step (2) dropwise to the core material emulsion obtained in step (1), and react for 3 hours; filter the product under reduced pressure, and wash it successively with absolute ethanol and water Several times, dry in a 50°C oven to obtain phase-change microcapsules; ...

Embodiment 2

[0051] A kind of phase change thermal storage paint, its preparation method comprises the following steps:

[0052] (1) 25g of lauryl alcohol, 1.5g of styrene maleic anhydride sodium salt and 50g of water were stirred at a high speed at 40°C, and the pH was adjusted to 3-4 with citric acid to obtain a core material emulsion;

[0053] (2) Add 11g of melamine, 21.5g of formaldehyde and 10g of graphene oxide aqueous dispersion into a round bottom flask, heat and stir until the liquid becomes clear, adjust the pH of the liquid to 8-9 with MA-95, and continue at 70°C React for 3h to obtain a solution containing the wall material prepolymer;

[0054] (3) Slowly add the solution containing the wall material prepolymer in step (2) dropwise to the core material emulsion obtained in step (1), and react for 3 hours; filter the product under reduced pressure, and wash it successively with absolute ethanol and water Several times, dry in a 50°C oven to obtain phase-change microcapsules; ...

Embodiment 3

[0062] A kind of phase change thermal storage paint, its preparation method comprises the following steps:

[0063] (1) 25g of lauryl alcohol, 1.5g of styrene maleic anhydride sodium salt and 50g of water were stirred at a high speed at 40°C, and the pH was adjusted to 3-4 with citric acid to obtain a core material emulsion;

[0064] (2) Add 11g of melamine, 21.5g of formaldehyde and 10g of graphene oxide aqueous dispersion into a round bottom flask, heat and stir until the liquid becomes clear, adjust the pH of the liquid to 8-9 with MA-95, and continue at 70°C React for 3h to obtain a solution containing the wall material prepolymer;

[0065] (3) The solution containing the wall material prepolymer in step (2) is slowly added dropwise to the core material emulsion obtained in step (1), and the reaction is continued for 3 hours; Wash several times and dry in an oven at 50°C to obtain phase change microcapsules;

[0066] (4) Use the phase-change microcapsules obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com